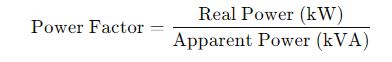

Power Factor Formula

Power factor is a critical aspect of electrical systems that measures the efficiency of power usage. It represents the ratio between real power, which performs work, and apparent power, which flows to the equipment. A high power factor indicates efficient utilization of electrical power, leading to reduced energy losses and lower electricity costs. The power factor formula, defined as Power Factor = Real Power (kW) / Apparent Power (kVA), plays a pivotal role in assessing and improving system performance. By leveraging this formula, we can identify inefficiencies and implement corrective measures.

In this blog post, we will explore seven advanced tips for enhancing your power factor using the power factor formula. These tips will help you optimize energy consumption, reduce operational costs, and achieve superior system efficiency. Let’s delve into these strategies and unlock the full potential of your electrical systems.

7 The Most Amazing Tips for Boost

Power Factor on a Ship

Power factor is an important electrical parameter that indicates the efficiency of power usage on a ship. It is the ratio of real power (measured in kilowatts, kW) to apparent power (measured in kilovolt-amperes, kVA) in an electrical system. It provides a measure of how effectively electrical power is being used to perform work.

Key Concepts:

- Real Power (kW): This is the actual power used by the ship’s electrical equipment to perform useful work, like running motors, lighting, or navigation systems.

- Apparent Power (kVA): This is the total power supplied to the ship, which includes both real power and reactive power (power that does no useful work but is needed to maintain magnetic fields in inductive loads).

- Reactive Power (kVAR): Power that supports the magnetic fields in equipment such as motors and transformers but does not perform actual work.

The formula for power factor is:

Ideal vs. Poor Power Factor:

- Ideal Power Factor: An ideal power factor is 1 (or 100%), which means that all the supplied electrical power is being used efficiently for work. In practice, power factor values typically range from 0.8 to 1.

- Poor Power Factor: A lower power factor (below 1) means more reactive power is present, causing inefficiencies. For instance, a power factor of 0.7 means that only 70% of the supplied power is used for work, while the rest is reactive power, causing unnecessary load on the generators.

Why Power Factor Matters on a Ship:

- Fuel Efficiency: A low power factor results in inefficiencies that can lead to higher fuel consumption because the ship’s generators must produce more apparent power to meet the same demand for real power.

- Equipment Overload: A poor power factor can cause generators and electrical equipment to run hotter, potentially leading to overheating and reduced lifespan of electrical components.

- Voltage Stability: Maintaining a good power factor helps stabilize voltage levels onboard, ensuring that electrical systems operate smoothly without fluctuations.

Improving Power Factor on Ships:

- Power Factor Correction: Ships often use capacitors or synchronous condensers to improve power factor. Capacitors provide reactive power, reducing the burden on the generators and improving overall efficiency.

- Efficient Equipment: Using more efficient motors and equipment with lower reactive power demands can also help improve power factor.

In-Depth Explanation of the Power Factor Formula

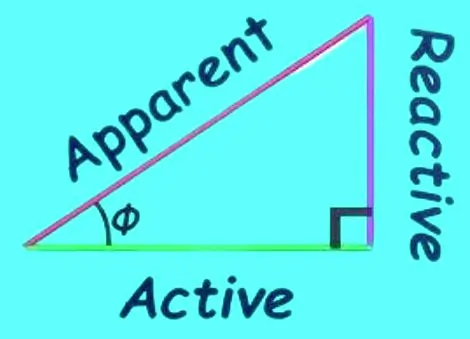

The power factor formula calculates the ratio of real power to apparent power, incorporating the phase angle (θ) between the current and voltage waveforms. Real power, measured in kilowatts (kW), represents the actual work done by electrical energy. Apparent power, measured in kilovolt-amperes (kVA), is the total power supplied by the source, combining both real and reactive power.

Detailed Discussion of Real Power, Reactive Power, and Apparent Power

- Real Power (P): The useful power that performs actual work, such as turning motors or lighting lamps.

- Reactive Power (Q): The power consumed in maintaining the electric and magnetic fields in inductive and capacitive loads. It does not perform any useful work but is necessary for the functioning of AC systems.

- Apparent Power (S): The combination of real power and reactive power. It represents the total power supplied by the source to produce both the actual work and maintain the electric fields.

The Significance of Phase Angle in Power Factor Calculation

The phase angle, represented by θ (theta), is the angle of difference between the current and voltage waveforms in an AC system. It plays a crucial role in power factor calculation. A smaller phase angle indicates a higher power factor, meaning the current and voltage are more in sync, leading to better efficiency. Conversely, a larger phase angle signifies a lower power factor, indicating inefficiencies due to the lag or lead between current and voltage. Understanding and managing the phase angle is vital for optimizing power factor and improving overall system performance.

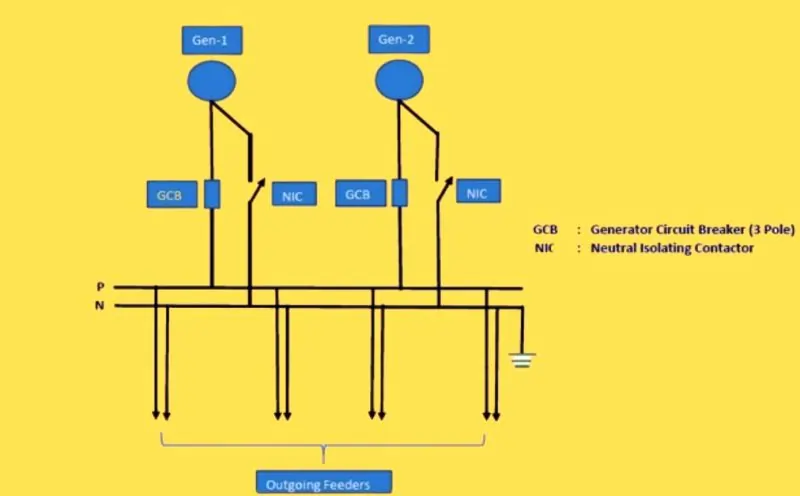

Power Factor in Generator Synchronization

Power factor plays a crucial role in the paralleling and synchronization of generators. Proper synchronization ensures that multiple generators can operate together efficiently, sharing the load and maintaining system stability. Here’s an in-depth look at why power factor is significant in this process:

Understanding Paralleling and Synchronization

Paralleling generators involves connecting two or more generators to work together as a single power source. Synchronization is the process of matching the voltage, frequency, phase angle, and waveform of these generators before they are connected to a common bus. Successful synchronization ensures that generators share the load evenly and operate efficiently without causing instability or damage.

Role of Power Factor in Synchronization

- Voltage Matching:

- Power factor influences the voltage levels of generators. A poor power factor can cause voltage fluctuations, making it difficult to match the voltages of generators accurately.

- Maintaining a high power factor ensures stable voltage levels, facilitating smoother synchronization.

- Phase Angle Alignment:

- The phase angle, which is directly related to power factor, must be aligned between generators. Any misalignment can lead to circulating currents and potential damage.

- A consistent power factor helps in maintaining the correct phase angle, making it easier to align generators during synchronization.

- Load Sharing:

- Generators must share the load proportionately based on their capacities. An unbalanced power factor can cause uneven load sharing, leading to inefficiencies and potential overloading of one or more generators.

- By optimizing the power factor, load sharing becomes more efficient, preventing overloading and ensuring balanced operation.

- System Stability:

- Synchronizing generators with different power factors can lead to instability, with potential oscillations and fluctuations in the power supply.

- A high and stable power factor contributes to overall system stability, minimizing the risk of power fluctuations and ensuring a steady power supply.

- Reactive Power Management:

- Reactive power, influenced by the power factor, affects the ability of generators to support inductive loads. Poor reactive power management can lead to voltage drops and instability.

- Proper synchronization includes managing reactive power to maintain voltage stability and system reliability.

Benefits of Maintaining High Power Factor During Synchronization

- Improved Efficiency: High power factor reduces losses in the system, ensuring that more of the generated power is used effectively.

- Reduced Stress on Generators: Balanced load sharing and voltage stability decrease mechanical and electrical stress on generators, extending their lifespan.

- Enhanced Reliability: Stable synchronization minimizes the risk of power interruptions and system failures, ensuring a reliable power supply.

- Cost Savings: Efficient operation and reduced losses lead to lower operational costs and energy savings.

Precision in Measurement Techniques

Accurate measurement of power factors is essential for optimizing electrical system efficiency. Advanced techniques and high-precision instruments play a critical role in ensuring precise calculations of real power (kW) and apparent power (kVA). Here’s how these advanced methods and tools can enhance power factor measurement:

Advanced Techniques for Measuring Real and Apparent Power

- Digital Power Analyzers: Utilize digital power analyzers for real-time monitoring and precise measurements of real and apparent power. These devices can capture instantaneous power values, providing accurate and detailed data.

- Smart Meters: Employ smart meters that use advanced algorithms to calculate power consumption accurately. Smart meters can distinguish between real and reactive power, ensuring precise power factor calculation.

- Data Loggers: Implement data loggers to record power usage over time. These devices help in analyzing power trends and identifying periods of inefficiency, allowing for targeted improvements.

High-Precision Instruments and Their Role in Power Factor Calculation

- True RMS Meters: Use True RMS (Root Mean Square) meters to measure AC power accurately. Unlike standard meters, True RMS meters can handle complex waveforms and provide precise readings of real power.

- Power Quality Analyzers: Deploy power quality analyzers to measure various power parameters, including voltage, current, and harmonics. These analyzers help in identifying power quality issues that affect the power factor.

- Phasor Measurement Units (PMUs): Incorporate PMUs for high-speed, synchronized measurements of electrical waveforms. PMUs provide accurate phase angle data, crucial for calculating power factor in complex systems.

Addressing Complex Measurement Challenges in Different Environments

- Industrial Settings: In industrial environments with heavy machinery, use robust instruments that can withstand high temperatures, vibrations, and electrical noise. Advanced shielding and filtering techniques can help mitigate measurement interference.

- Commercial Buildings: In commercial buildings with varied load types, employ versatile instruments capable of measuring both linear and non-linear loads accurately. Ensure regular calibration of instruments to maintain measurement accuracy.

- Remote Locations: For remote or harsh environments, use portable, battery-operated instruments designed for field use. Ensure that these instruments have adequate data storage and communication capabilities for remote data analysis.

Precision in Measurement Techniques

| Guideline | Description |

|---|---|

| Precision in Measurement Techniques | Accurate measurement of power factors is essential for optimizing electrical system efficiency. Advanced techniques and high-precision instruments play a critical role in ensuring precise calculations of real power (kW) and apparent power (kVA). |

| Advanced Techniques for Accurately Measuring Real and Apparent Power | Digital Power Analyzers: Utilize digital power analyzers for real-time monitoring and precise measurements of real and apparent power. These devices can capture instantaneous power values, providing accurate and detailed data. Smart Meters: Employ smart meters that use advanced algorithms to calculate power consumption accurately. Smart meters can distinguish between real and reactive power, ensuring precise power factor calculation. Data Loggers: Implement data loggers to record power usage over time. These devices help in analyzing power trends and identifying periods of inefficiency, allowing for targeted improvements. |

| High-Precision Instruments and Their Role in Power Factor Calculation | True RMS Meters: Use True RMS (Root Mean Square) meters to measure AC power accurately. Unlike standard meters, True RMS meters can handle complex waveforms and provide precise readings of real power. Power Quality Analyzers: Deploy power quality analyzers to measure various power parameters, including voltage, current, and harmonics. These analyzers help in identifying power quality issues that affect the power factor. Phasor Measurement Units (PMUs): Incorporate PMUs for high-speed, synchronized measurements of electrical waveforms. PMUs provide accurate phase angle data, crucial for calculating power factor in complex systems. |

| Addressing Complex Measurement Challenges in Different Environments | Industrial Settings: In industrial environments with heavy machinery, use robust instruments that can withstand high temperatures, vibrations, and electrical noise. Advanced shielding and filtering techniques can help mitigate measurement interference. Commercial Buildings: In commercial buildings with varied load types, employ versatile instruments capable of measuring both linear and non-linear loads accurately. Ensure regular calibration of instruments to maintain measurement accuracy. Remote Locations: For remote or harsh environments, use portable, battery-operated instruments designed for field use. Ensure that these instruments have adequate data storage and communication capabilities for remote data analysis. |

Integrating Power Factor Formula in Load Flow Analysis

Integrating the power factor formula into load flow analysis is essential for optimizing the performance and efficiency of electrical grids. This process involves utilizing the power factor formula to assess and enhance the distribution of electrical power across the grid, ensuring stability, reducing losses, and improving overall system efficiency. Here’s a detailed look at how to effectively integrate the power factor formula in load flow analysis:

Utilizing the Power Factor Formula in Load Flow Analysis for Electrical Grids

The power factor formula, Power Factor (PF) = Real Power (P) / Apparent Power (S), is crucial in load flow analysis as it helps determine the efficiency of power usage within the grid. By calculating the power factor for different segments of the grid, operators can identify areas where power is being used inefficiently and make necessary adjustments. This ensures that the real power delivered to the load is maximized while minimizing losses associated with reactive power.

Advanced Load Flow Analysis Techniques and Software Tools

Advanced techniques and software tools are vital for accurate load flow analysis. Some of the most effective methods and tools include:

- Newton-Raphson Method: A widely used iterative method for solving nonlinear equations in load flow analysis. It offers fast convergence and high accuracy, making it suitable for large and complex power systems.

- Fast Decoupled Load Flow (FDLF) Method: This method simplifies the load flow problem by decoupling active and reactive power equations, resulting in faster computation times and reduced memory requirements.

- Gauss-Seidel Method: An iterative technique that is easy to implement and useful for small to medium-sized power systems. It provides good initial estimates for more advanced methods.

- Power System Analysis Software (PSA): Tools like ETAP, PSS/E, and DIgSILENT PowerFactory offer comprehensive load flow analysis capabilities. These software tools incorporate the power factor formula, allowing for detailed analysis and optimization of power distribution.

Case Studies on Optimizing Load Flow Using Power Factor Data

Real-world case studies highlight the importance of integrating power factor data in load flow analysis to optimize grid performance:

- Case Study 1: Industrial Power System Optimization

- Background: A large industrial facility experienced frequent voltage fluctuations and high energy costs.

- Approach: Load flow analysis was conducted using the power factor formula to identify areas with poor power factor.

- Solution: Capacitor banks were installed to correct the power factor, and the load flow analysis was used to optimize their placement.

- Results: The facility achieved a 15% reduction in energy costs and improved voltage stability.

- Case Study 2: Urban Distribution Network Efficiency

- Background: An urban distribution network faced issues with energy losses and low power factor in certain areas.

- Approach: Advanced load flow analysis techniques were employed, utilizing power factor data to pinpoint problem areas.

- Solution: Reactive power compensation devices were strategically installed, and load flow analysis was used to fine-tune their settings.

- Results: The network saw a 10% decrease in energy losses and a significant improvement in overall efficiency.

- Case Study 3: Renewable Energy Integration

- Background: A utility company integrating renewable energy sources faced challenges with power quality and grid stability.

- Approach: Load flow analysis incorporating the power factor formula was used to assess the impact of renewable energy on the grid.

- Solution: Advanced control strategies and power factor correction were implemented based on the analysis.

- Results: Enhanced grid stability and improved power quality, with a seamless integration of renewable energy sources.

Harmonics and Their Impact on Power Factor

| Guideline | Description |

|---|---|

| Understanding the Role of Harmonics in Power Factor Degradation | Harmonics are voltage or current waveforms that are integer multiples of the fundamental frequency. They distort the waveform, causing a decrease in power quality and power factor. High harmonic content leads to increased reactive power, thus lowering the power factor. This can result in inefficient power usage and potential damage to electrical equipment. |

| Advanced Methods for Measuring and Mitigating Harmonics | Harmonic Analyzers: Utilize harmonic analyzers to measure the harmonic content in electrical systems accurately. These devices provide detailed harmonic spectrum analysis, helping identify the sources and levels of harmonics. Power Quality Meters: Deploy power quality meters that can measure voltage, current, and harmonic distortion simultaneously. These meters offer real-time monitoring and data logging capabilities. Filters and Compensators: Implement harmonic filters (passive, active, or hybrid) to mitigate harmonic distortion. These devices are designed to eliminate specific harmonic frequencies, thus improving the power factor. Custom-designed compensators can also be used to neutralize harmonic effects. |

| Using the Power Factor Formula to Analyze Harmonic Impacts | The power factor formula, Power Factor (PF) = Real Power (P) / Apparent Power (S), can be used to analyze the impact of harmonics on power factor. Harmonics increase the apparent power (S) without contributing to real power (P), thus lowering the power factor. By measuring real power and apparent power, and analyzing the harmonic content, one can determine the extent to which harmonics degrade the power factor. Advanced software tools can also simulate harmonic impacts and help in designing effective mitigation strategies. |

Power Factor Formula in Energy Management Systems

Integrating the power factor formula into comprehensive energy management systems is crucial for optimizing energy consumption, reducing costs, and enhancing the efficiency of electrical systems. Here’s a detailed description of how the power factor formula can be utilized within energy management systems:

Integration of Power Factor Formula in Comprehensive Energy Management Systems

The power factor formula, Power Factor (PF) = Real Power (P) / Apparent Power (S), is a vital tool for assessing and improving the efficiency of energy usage. By incorporating this formula into energy management systems, operators can monitor and control the power factor across different segments of the electrical network. This integration enables real-time analysis and corrective actions, ensuring that energy is used efficiently and effectively.

- Real-Time Monitoring: Advanced sensors and meters continuously measure real power and apparent power, providing accurate and up-to-date power factor data.

- Automated Control: Energy management systems can automatically adjust reactive power compensation devices, such as capacitors and inductors, to maintain an optimal power factor.

- Data Analytics: The system collects and analyzes power factor data, identifying trends and anomalies that can indicate inefficiencies or potential issues.

Advanced Energy Management Strategies Leveraging Power Factor Data

Utilizing power factor data within energy management strategies can lead to significant improvements in system performance and energy savings. Some advanced strategies include:

- Load Balancing: By analyzing power factor data, operators can identify imbalances in the system and redistribute loads to maintain a stable power factor, reducing losses and improving efficiency.

- Demand Response: Power factor data helps in implementing demand response strategies, where the system adjusts energy consumption during peak periods to maintain an optimal power factor and reduce demand charges.

- Predictive Maintenance: Continuous monitoring of power factor data can predict potential equipment failures or inefficiencies, allowing for proactive maintenance and reducing downtime.

FAQ on the “Power Factor Formula”

Q1: What is the power factor formula?

A1: The power factor formula is PF = Real Power (P) / Apparent Power (S).

Q2: Why is a high power factor important?

A2: A high power factor indicates efficient use of electrical power, reducing energy losses and costs.

Q3: How can I improve my power factor?

A3: Improve power factor by using capacitors, power factor correction devices, and load balancing.

Q4: What tools measure power factor accura

A4: Tools like digital power analyzers, smart meters, and power quality analyzers measure power factor accurately.

Conclusion

Optimizing power factor is essential for enhancing the efficiency and reliability of electrical systems. By integrating the power factor formula into energy management practices, you can achieve significant energy savings, reduce operational costs, and improve system performance. Advanced techniques and tools for measuring and analyzing power factor, along with strategic approaches to load balancing, demand response, and predictive maintenance, offer substantial benefits. Real-world case studies highlight the success and practicality of these methods. Embrace these strategies to unlock the full potential of your energy management system and ensure a sustainable, efficient, and cost-effective power infrastructure.