Power Transformers

Power transformers play a crucial role in modern electrical systems, ensuring the efficient transmission and distribution of electricity over long distances. These devices adjust voltage levels, enabling us to enjoy reliable power in our homes, businesses, and industries. Despite their importance, many people aren’t familiar with the details and innovations that make power transformers so vital.

In this blog post, we’ll uncover nine amazing facts about power transformers that will enhance your understanding and appreciation of their functionality. From the different types and specifications to the latest technological advancements and their contributions to energy efficiency, you’ll get a comprehensive look at why power transformers are indispensable in our daily lives. Let’s explore the fascinating world of power transformers and discover what makes them truly remarkable.

What Are Power Transformers?

Definition

Power transformers are electrical devices used to transfer electrical energy between two or more circuits through electromagnetic induction. They are essential components in electrical power systems, designed to change the voltage levels of electrical power, either stepping up (increasing) or stepping down (decreasing) the voltage to meet the requirements of different applications.

Basic Working Principle

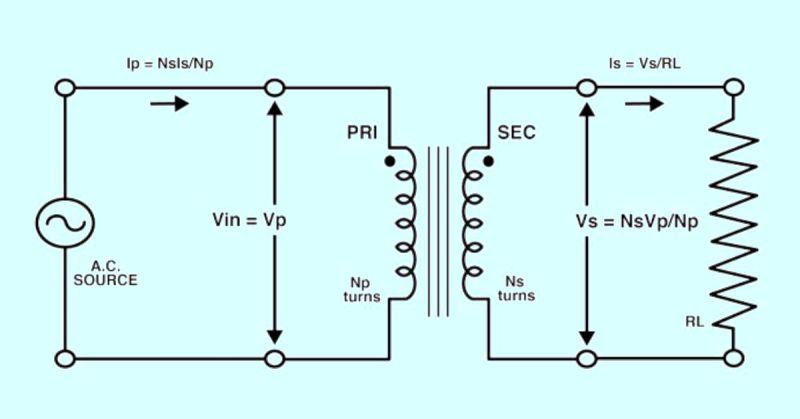

Power transformers operate on the principle of electromagnetic induction. They consist of two main parts: the primary winding and the secondary winding, both of which are wrapped around a magnetic core. When an alternating current (AC) flows through the primary winding, it generates a magnetic field in the core. This magnetic field induces a voltage in the secondary winding, thus transferring electrical energy from the primary to the secondary circuit. The voltage level in the secondary winding depends on the ratio of the number of turns in the primary winding to the number of turns in the secondary winding, known as the turn ratio.

Importance in Electrical Systems

Power transformers play a critical role in the transmission and distribution of electrical power. In power generation plants, they step up the voltage to high levels to minimize energy losses during long-distance transmission. High-voltage transmission reduces the current flowing through the lines, which in turn reduces resistive losses. When the electrical power reaches substations near the consumption areas, step-down transformers reduce the voltage to safer, usable levels suitable for homes, businesses, and industrial facilities. This efficient voltage regulation ensures the reliable and safe delivery of electricity from power plants to end users, making power transformers indispensable in modern electrical systems.

Types of Power Transformers

Step-Up and Step-Down Transformers

Step-Up Transformers: These transformers increase the voltage from a lower level to a higher level. They are primarily used in power generation stations where the voltage generated by the alternators is stepped up for efficient transmission over long distances. By increasing the voltage, step-up transformers reduce the current in the transmission lines, minimizing energy losses due to resistance.

Applications: Step-up transformers are crucial in power plants and renewable energy installations like solar farms and wind turbines, where they raise the generated voltage to suitable levels for long-distance transmission.

Step-Down Transformers: These transformers decrease the voltage from a higher level to a lower level. They are typically used in substations and near end-user locations to step down the high transmission voltage to safer, usable levels for residential, commercial, and industrial use.

Applications: Step-down transformers are widely used in electrical distribution systems to provide the appropriate voltage levels for consumer devices and equipment.

Isolation Transformers

Purpose: Isolation transformers are designed to isolate the primary and secondary windings, providing electrical separation between the two circuits. This isolation enhances safety by preventing direct electrical connection, which can protect against electric shocks and reduce noise in sensitive equipment.

Benefits:

- Safety: Isolation transformers are used in medical equipment, laboratory instruments, and other sensitive applications to ensure safety by isolating the user from the high voltage.

- Noise Reduction: They help in minimizing electrical noise and interference, making them ideal for use in communication systems, audio equipment, and industrial control systems.

Applications: Isolation transformers are commonly used in sensitive electronic equipment, industrial machinery, and healthcare devices to provide a clean and safe power supply.

Distribution Transformers

Use in Power Distribution Networks: Distribution transformers are essential components in the electrical distribution system. They step down the voltage from high levels used in transmission lines to lower levels suitable for use in homes, businesses, and industries. Unlike power transformers used in generation and transmission, distribution transformers are typically located closer to the end users and are designed for continuous operation at or near their rated capacity.

Applications:

- Residential Areas: Distribution transformers provide the final voltage transformation in the electric power distribution system, delivering the appropriate voltage to households.

- Commercial and Industrial Facilities: These transformers supply power to commercial buildings, factories, and other industrial facilities, ensuring the machinery and equipment operate efficiently and safely.

- Renewable Energy Systems: In renewable energy systems, distribution transformers connect solar panels and wind turbines to the local grid, stepping down the voltage as needed.

Specifications and Ratings

| Aspect | Description |

|---|---|

| Voltage and Power Ratings | Transformers are rated based on their primary and secondary voltage levels, as well as their power handling capacity, typically expressed in kilovolt-amperes (kVA) or megavolt-amperes (MVA). The voltage rating indicates the maximum voltage the transformer can handle without breakdown, while the power rating indicates the maximum amount of electrical power the transformer can deliver. Properly matching these ratings to the application ensures safe and efficient operation. |

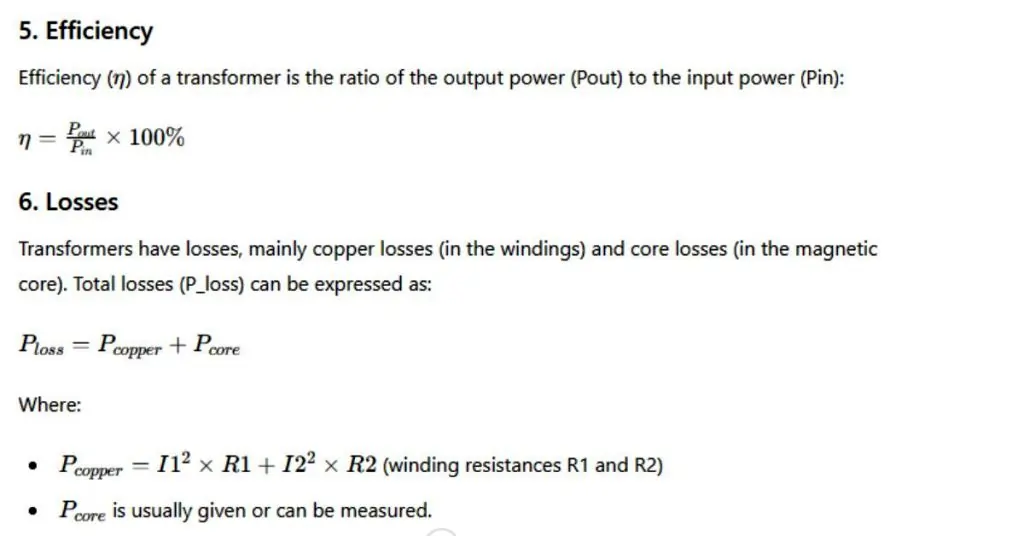

| Efficiency Ratings | Efficiency in power transformers is crucial as it determines the amount of power loss during operation. Efficiency is typically expressed as a percentage and calculated by comparing the output power to the input power. Higher efficiency ratings mean less energy is wasted as heat, resulting in lower operating costs and better performance. Efficiency is especially important in large-scale power transmission, where even small losses can translate into significant energy waste. |

| Cooling Methods | Oil-Cooled Transformers: These use mineral oil or synthetic oil to dissipate heat generated during operation. The oil circulates through the transformer, absorbing heat from the core and windings, and then passes through a radiator or cooling fins where the heat is released into the surrounding air. Oil-cooled transformers are highly efficient in heat dissipation and are commonly used in high-power applications. Air-Cooled Transformers: Also known as dry-type transformers, these use air as the cooling medium. The heat generated is dissipated through natural convection or forced air circulation using fans. Air-cooled transformers are generally used in lower power applications or where oil is not suitable due to environmental or safety concerns. They require less maintenance but may not be as efficient in cooling as oil-cooled transformers. |

Power Transformer Calculations and Key Formulas

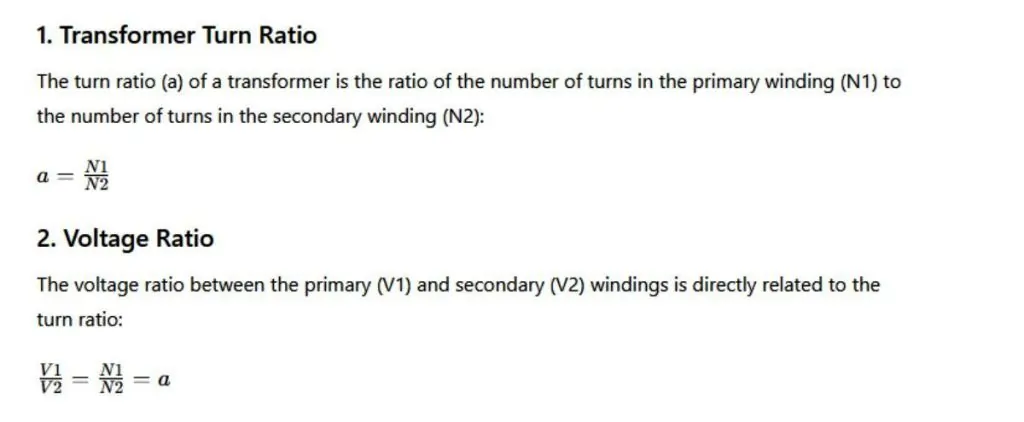

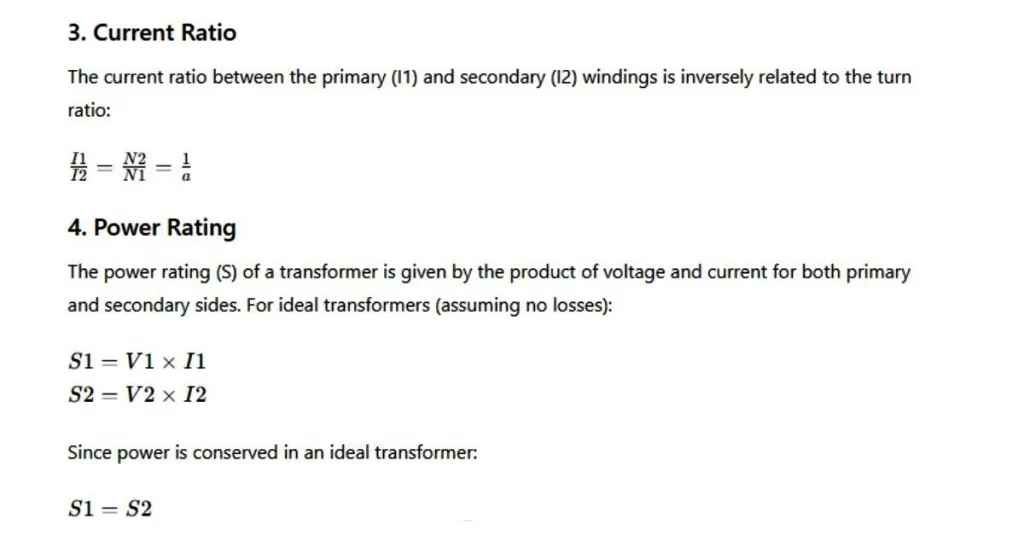

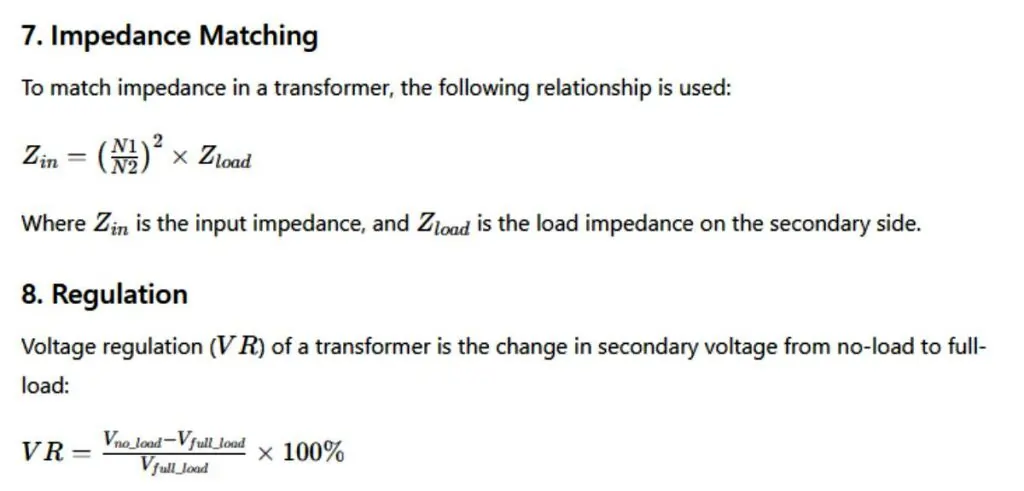

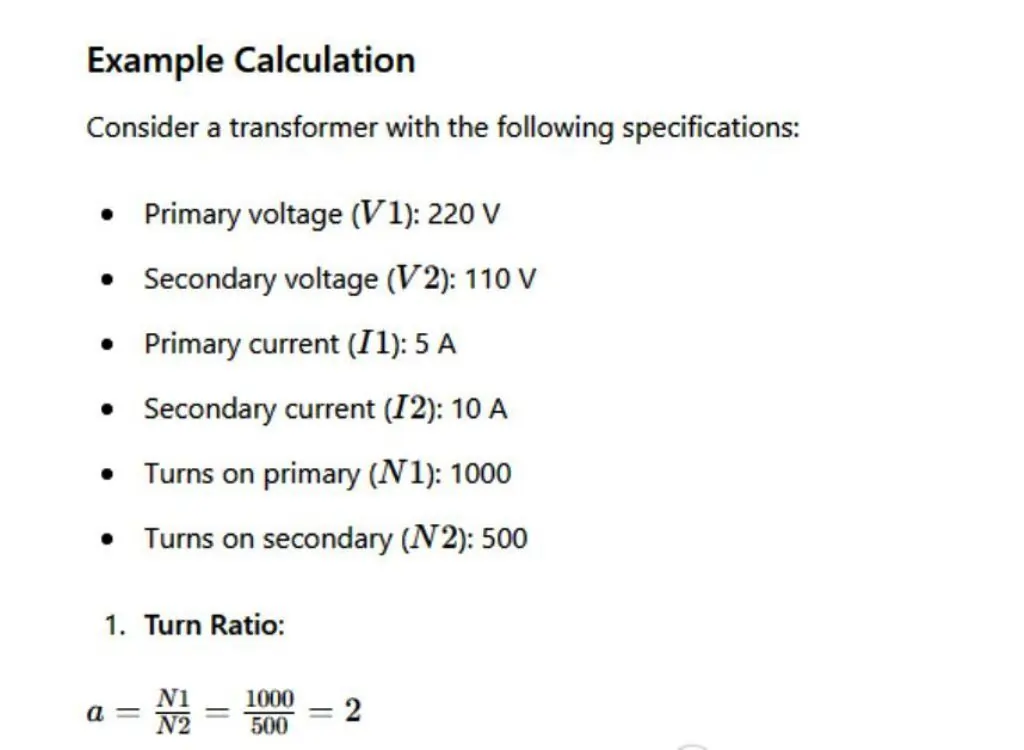

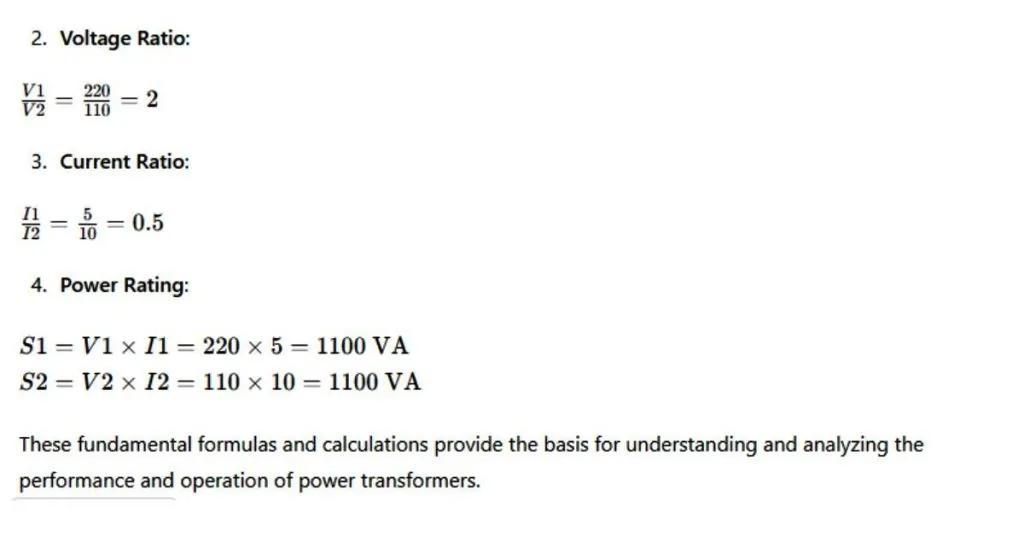

Power transformer calculations often involve several key parameters and formulas to determine their performance and characteristics. Below are some fundamental formulas used in power transformer working calculations:

Installation and Usage

Residential Applications

Power transformers play a critical role in residential settings by ensuring that homes receive electricity at a safe and usable voltage level. Typically, power from the grid is transmitted at high voltages to minimize energy loss during distribution. Near residential areas, step-down transformers are used to reduce this high voltage to a lower level suitable for household appliances and lighting. These transformers are often mounted on poles or installed in substations and are vital for maintaining a stable and reliable power supply to homes, protecting electrical devices from voltage fluctuations and ensuring safety.

Commercial and Industrial Uses

In commercial and industrial environments, power transformers are essential for managing the significant electrical demands of these settings. Commercial buildings, such as offices, shopping centers, and hospitals, use transformers to step down the high voltage from the grid to levels suitable for lighting, HVAC systems, and other equipment. In industrial facilities, transformers are often used to provide power to heavy machinery, manufacturing equipment, and other high-demand applications. These transformers must handle large loads and ensure continuous, reliable power to support complex operations. Additionally, industrial transformers may have specialized features to withstand harsh conditions, such as high temperatures and vibrations.

Installation Guidelines

Proper installation of power transformers is crucial for their efficient and safe operation. Here are some key guidelines:

- Site Selection:

- Choose a location with adequate space for installation and maintenance.

- Ensure the site is well-ventilated to facilitate cooling.

- Avoid areas prone to flooding or extreme weather conditions.

- Foundation and Mounting:

- Install the transformer on a solid, level foundation to prevent vibrations and movement.

- Use appropriate mounting hardware to secure the transformer in place.

- Electrical Connections:

- Follow the manufacturer’s wiring diagrams and guidelines.

- Ensure all connections are tight and secure to prevent arcing and overheating.

- Use proper insulation and grounding techniques to enhance safety.

- Cooling and Ventilation:

- For oil-cooled transformers, ensure the cooling radiators or fins are free from obstructions.

- For air-cooled transformers, provide adequate clearance around the unit for airflow.

- Regularly inspect and maintain cooling systems to ensure efficient heat dissipation.

- Safety Measures:

- Install protective devices such as circuit breakers and fuses to prevent overloads.

- Use signage and barriers to restrict access to the transformer area.

- Follow all local electrical codes and standards to ensure compliance and safety.

- Testing and Commissioning:

- Perform insulation resistance tests and other electrical tests before energizing the transformer.

- Check for any signs of damage or defects.

- Gradually apply power and monitor the transformer for stable operation.

Maintenance and Troubleshooting

| Aspect | Description |

|---|---|

| Routine Maintenance Tips | Visual Inspections: Regularly inspect the transformer for signs of oil leaks, corrosion, and physical damage. Oil Analysis: For oil-cooled transformers, periodically test the oil for contaminants and degradation. Cleaning: Keep the transformer and surrounding area clean to prevent dust and debris buildup, which can affect cooling. Cooling System Check: Ensure that cooling systems (radiators, fans, etc.) are functioning correctly. Electrical Testing: Conduct insulation resistance tests, winding resistance tests, and other electrical tests to monitor the transformer’s condition. Tightening Connections: Check and tighten all electrical connections to prevent arcing and overheating. Load Monitoring: Monitor the load on the transformer to ensure it is operating within its rated capacity. Temperature Monitoring: Regularly check the temperature of the transformer to detect overheating issues early. |

| Common Issues | Overheating: Caused by excessive load, poor ventilation, or cooling system failure. Address by reducing the load, improving ventilation, or repairing the cooling system. Oil Leaks: Can lead to insulation breakdown and overheating. Identify and repair leaks promptly. Electrical Arcing: Due to loose connections or insulation failure. Tighten connections and replace damaged insulation. Corrosion: Affects the structural integrity and performance. Regular cleaning and protective coatings can prevent corrosion. Noise: Unusual sounds may indicate internal issues such as loose components or magnetic flux problems. Investigate and resolve the source of noise. |

| Troubleshooting Guide | Overheating: 1. Check the load and reduce if necessary. 2. Inspect and clean cooling systems. 3. Verify the ventilation around the transformer. 4. Check for oil levels and top up if required. <br> 5. Perform electrical tests to identify internal faults. Oil Leaks: 1. Identify the source of the leak. 2. Tighten or replace leaking gaskets and seals. 3. Drain and refill the oil if contaminated. 4. Conduct oil analysis to ensure oil quality. Electrical Arcing: 1. Turn off the transformer and disconnect from the circuit. 2. Inspect all electrical connections and tighten them. 3. Replace damaged insulation materials. 4. Conduct a thorough electrical test before re-energizing. Corrosion: 1. Inspect for signs of rust and corrosion. 2. Clean the affected areas and apply anti-corrosion coatings. 3. Replace severely corroded components. Noise: 1. Identify the type and source of the noise. 2. Tighten any loose components. 3. Check for magnetic flux leakage and address as needed. 4. Consult with a specialist if the noise persists. |

Safety and Standards of Power Transformers

| Aspect | Description |

|---|---|

| Safety Precautions | Proper Training: Ensure personnel handling transformers are adequately trained and knowledgeable about safety protocols. Personal Protective Equipment (PPE): Use appropriate PPE such as gloves, safety glasses, and insulated tools. De-energize Before Maintenance: Always de-energize and lock out transformers before performing any maintenance work. Grounding: Properly ground the transformer and associated equipment to prevent electric shock and ensure safe operation. Clear Signage: Display clear warning signs and safety instructions around transformer installations. Safe Distance: Maintain a safe distance from live parts and ensure non-authorized personnel are kept away. Regular Inspections: Conduct regular safety inspections to identify and mitigate potential hazards. Emergency Procedures: Establish and train staff on emergency procedures in case of transformer failure or fire. |

| Industry Standards and Certifications | IEEE Standards: The Institute of Electrical and Electronics Engineers (IEEE) provides comprehensive standards for transformer design, testing, and operation, including IEEE C57 series. These standards ensure reliability, safety, and performance. IEC Standards: The International Electrotechnical Commission (IEC) sets global standards for electrical, electronic, and related technologies. Key standards for transformers include IEC 60076 series, covering general requirements, temperature rise, insulation, and more. ANSI Standards: The American National Standards Institute (ANSI) also provides standards for transformers, ensuring they meet specific performance and safety criteria in the US. ISO Certifications: International Organization for Standardization (ISO) certifications, such as ISO 9001 for quality management and ISO 14001 for environmental management, help manufacturers maintain high standards in transformer production. NEMA Standards: The National Electrical Manufacturers Association (NEMA) sets standards for electrical equipment, including transformers, ensuring they meet safety, efficiency, and performance requirements. UL Certification: Underwriters Laboratories (UL) certification ensures that transformers meet safety standards and have been tested for potential risks such as fire, electric shock, and mechanical hazards. |

Applications of Power Transformers in Various Sectors

| Aspect | Description |

|---|---|

| Energy Distribution | Power transformers are essential in both national and regional energy distribution networks. They step up the voltage at generation plants for efficient long-distance transmission, minimizing energy losses. Near consumption areas, step-down transformers reduce the voltage to safer levels for distribution to homes, businesses, and industries. This voltage regulation ensures the stable and efficient delivery of electricity, supporting the infrastructure needed for modern society. |

| Industrial Processes | In industrial settings, power transformers play a critical role by providing the necessary voltage levels for various manufacturing processes and heavy machinery operations. They ensure the continuous and reliable supply of electricity required for equipment such as motors, conveyors, welding machines, and other industrial tools. Transformers also help in managing voltage variations and protecting sensitive equipment from electrical surges, contributing to the overall efficiency and safety of industrial operations. |

| Renewable Energy Integration | Power transformers are vital in integrating renewable energy sources like solar and wind power into the grid. They step up the voltage generated by renewable energy installations to match the grid’s transmission voltage, facilitating efficient long-distance transport of green energy. Additionally, they play a crucial role in microgrids and distributed generation systems by managing voltage levels and ensuring the stability and reliability of renewable energy systems. This integration supports the transition to sustainable energy solutions and helps reduce the carbon footprint. |

FAQ on “Power Transformers”

Q: What is a power transformer?

A: It changes voltage levels for electricity transmission and distribution.

Q: What do step-up and step-down transformers do?

A: Step-up increases voltage; step-down decreases voltage.

Q: Why is transformer maintenance important?

A: It ensures efficiency and prevents failures.

Q: How do transformers aid renewable energy?

A: They match renewable energy voltage to grid standards.

Conclusion

Power transformers are indispensable components of modern electrical systems, ensuring the efficient transmission and distribution of electricity across various sectors. From residential applications to large-scale industrial processes and renewable energy integration, these transformers play a critical role in maintaining stable and reliable power. Understanding their types, specifications, maintenance, safety measures, and diverse applications enhances our appreciation of their functionality and importance. As technology advances, power transformers continue to evolve, contributing to a more efficient and sustainable energy future. Stay informed and embrace the remarkable world of power transformers to harness their full potential in powering our lives.