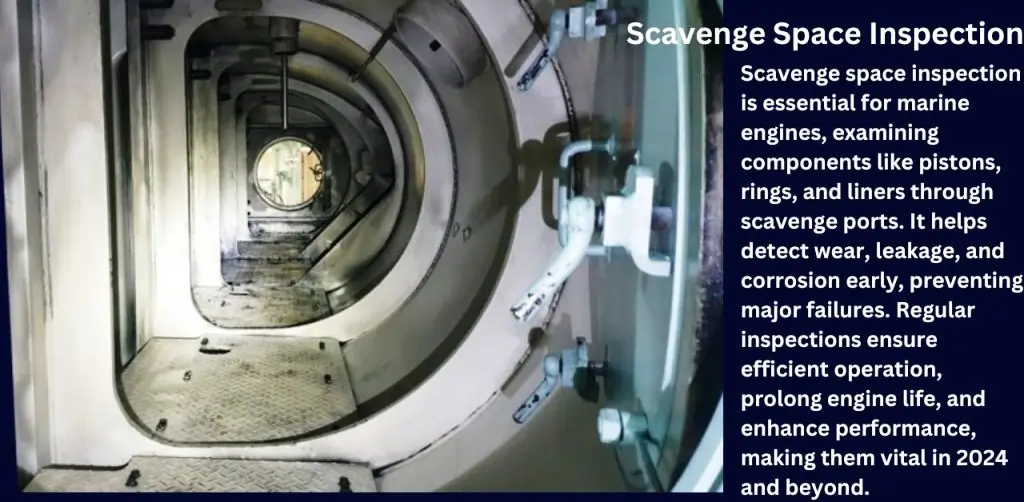

Scavenge Space Inspection

Scavenge space inspection is a vital maintenance procedure for marine engines, ensuring the engine operates efficiently and reliably. This inspection involves examining critical components like pistons, piston rings, and cylinder liners through scavenge ports, which provides valuable insight into the condition of the engine. By thoroughly inspecting these parts, engineers can detect early signs of leakage from pistons or cylinder covers and identify wear issues, such as frictional damage or corrosion on the liner surface. Early detection of these issues helps prevent costly repairs, maintains engine performance, and ensures the longevity of the vessel’s main engine.

Understanding Scavenge Space Inspection

Definition and Purpose: Scavenge space inspection is a critical process in marine engine maintenance, designed to assess the condition of internal engine components through scavenge ports. The primary purpose is to detect early signs of wear, corrosion, and leakage in key parts, ensuring the engine operates smoothly and efficiently.

Components Inspected: During the inspection, engineers focus on examining the following critical components:

- Pistons

- Piston Rings

- Cylinder Liners

- Scavenge Receiver

These parts are essential for the engine’s performance, and regular inspections help identify potential problems before they escalate into major failures.

Importance of Running Cooling Water and Lubricating Oil Pumps: During the scavenge space inspection, it’s crucial to keep the cooling water and lubricating oil pumps running. This ensures that the engine components remain at a stable temperature and are properly lubricated, minimizing the risk of damage during the inspection and maintaining engine safety.

Preparation for Scavenge Space Inspection

Permission & Immobilization: Before conducting a scavenge space inspection, it is crucial to obtain the necessary permissions from port authorities or the ship’s bridge for main engine immobilization. This ensures the engine can be safely inspected without disrupting operations.

Safety Precautions:

- Engine Stop Indicator Cock: Make sure the engine stop indicator cock is open to prevent any accidental start during the inspection.

- Turning Gear Engagement: Engage the turning gear to the main engine, allowing safe manual turning of the engine during inspection.

Pre-Inspection Checklist:

- Verify that the cooling water and lubrication systems are functioning to maintain proper temperature and lubrication of components.

- Prepare the required tools and safety equipment to ensure the inspection is carried out efficiently and safely.

Scavenge Space Inspection Procedure

Opening Scavenge Ports: To begin the scavenge space inspection, open all under-piston scavenge space doors as well as the scavenge air receiver door. This provides access to the critical components that need to be examined. Ensure proper ventilation of the scavenge space by using a portable blower, which will create a safe environment for inspection.

Inspection Steps:

- Inspect Piston Crown and Cylinder Wall: When the piston is positioned below the scavenge ports, carefully inspect the piston crown and the surface of the cylinder wall.

- Check for Frictional Wear: Examine the sliding surfaces of the cylinder liner and piston for signs of frictional wear, which can lead to reduced engine efficiency.

- Inspect for Acidic Corrosion: Look for acidic corrosion on the cylinder liner, typically manifesting in a distinctive clover leaf pattern.

- Examine for Abrasion: Check for evidence of abrasion caused by mechanical wear, corrosion, and combustion remnants, which can degrade the liner’s condition over time.

Detailed Inspection of Key Components

Piston Rings & Skirt:

- Turn the engine to bring the piston rings and skirt into view through the scavenge ports.

- Carefully inspect the piston rings for any signs of micro-seizures on both the rings and the cylinder liner surface, which can lead to reduced engine efficiency and potential damage.

- Verify the free movement and springiness of the piston rings by pressing them lightly. This ensures they are functioning correctly and maintaining proper sealing within the cylinder.

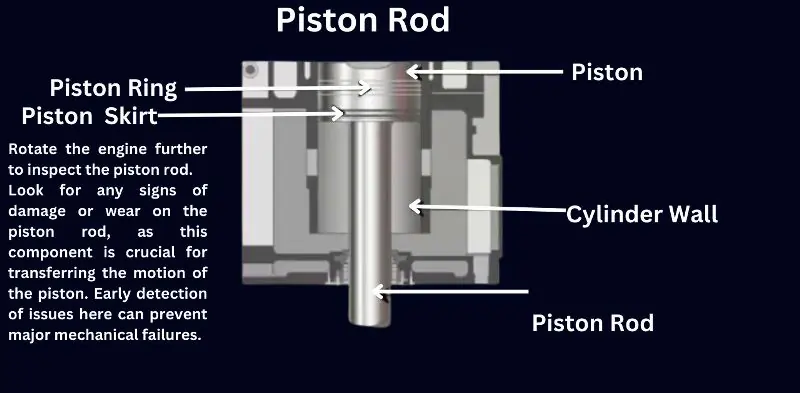

Piston Rod:

- Rotate the engine further to inspect the piston rod.

- Look for any signs of damage or wear on the piston rod, as this component is crucial for transferring the motion of the piston. Early detection of issues here can prevent major mechanical failures.

Common Issues Detected During Scavenge Space Inspections

Leakage from Pistons or Cylinder Covers: One of the most frequent issues detected during scavenge space inspections is leakage from the pistons or cylinder covers. This can lead to a loss of compression and reduced engine performance, requiring immediate attention to avoid further damage.

Acidic Corrosion on Cylinder Liners: Acidic corrosion is another common problem, often identifiable by a clover leaf pattern on the liner surface. This type of corrosion is caused by acidic combustion by-products and can lead to accelerated wear of the cylinder liner.

Mechanical Wear or Combustion-Related Damage on the Liner: Mechanical wear or damage resulting from combustion remnants is often observed during inspections. These issues can degrade the liner surface, reducing its efficiency and potentially causing engine failure if not addressed promptly.

Micro-Seizures on Piston Rings and Liner Surfaces: Micro-seizures, small localized welding of the piston rings to the liner surface, are a sign of inadequate lubrication or excessive friction. Detecting these early can help prevent more severe damage to the engine components.

Post-Inspection Guidelines

Record Findings and Document Issues: After completing the scavenge space inspection, it is essential to carefully record all observations. Document any detected issues such as wear, corrosion, or leakage. Accurate documentation ensures proper follow-up and maintenance scheduling.

Plan Maintenance or Part Replacement: Based on the inspection findings, plan for any necessary maintenance or part replacements. Addressing issues early, such as worn piston rings or damaged liners, helps prevent more extensive repairs and ensures the engine operates efficiently.

Ensure Proper Reassembly and Secure Closing of Scavenge Ports: Once the inspection and maintenance planning are complete, ensure the proper reassembly of all components. Double-check that all scavenge ports and doors are securely closed to prevent operational hazards or leaks when the engine is restarted. This final step ensures the safety and reliability of the engine post-inspection.

FAQ on Scavenge Space Inspection

Q: What is scavenge space inspection?

A: It’s the inspection of engine components like pistons and liners through scavenge ports.

Q: What are the two types of scavenging?

A: The two types are loop flow scavenging and uniflow scavenging.

Q: What is the scavenging space in the engine?

A: It’s the area where air is supplied to the cylinder for combustion.

Q: What is the importance of scavenge space inspection?

A: It helps detect wear, leakage, and corrosion in key engine components.

Conclusion

Scavenge space inspections are crucial for maintaining the efficiency and reliability of marine engines. By regularly inspecting critical components like pistons, rings, and liners, potential issues such as wear, corrosion, and leakage can be detected early, preventing costly engine failures. Consistent inspections ensure smooth engine operation, prolonging the life of essential parts and reducing the risk of unexpected breakdowns.