Step Up Transformer

In the dynamic world of modern electrical systems, step-up transformers play a crucial role in enhancing efficiency and ensuring reliable power transmission over long distances. Imagine a world where electricity could not be effectively transported from power plants to our homes and industries; step-up transformers are the unsung heroes preventing this scenario. They boost voltage levels, enabling the seamless flow of electricity, minimizing energy losses, and supporting our everyday needs. Unlike step-down transformers, which decrease voltage for safe use in homes and businesses, step-up transformers increase voltage for efficient long-distance power transmission.

In this blog post, we delve into the fascinating world of step-up transformers, unveiling seven powerful facts that highlight their significance, exploring the various types available, and showcasing their diverse applications. From renewable energy systems like wind farms to essential industrial uses, step-up transformers are integral to our electrical infrastructure. Join us as we uncover the technical specifications, installation best practices, and the latest technological advancements, ensuring you gain a comprehensive understanding of these vital components.

What is a Step-Up Transformer?

Basic Explanation

Definition and Core Purpose

A step-up transformer is a type of electrical transformer designed to increase (step up) the voltage from the primary side to the secondary side while maintaining the same frequency. Its core purpose is to boost the voltage of electrical power, making it suitable for efficient long-distance transmission. This helps in minimizing energy losses that occur due to resistance in the transmission lines, ensuring that electricity reaches its destination with minimal loss.

Principle of Operation

How It Works

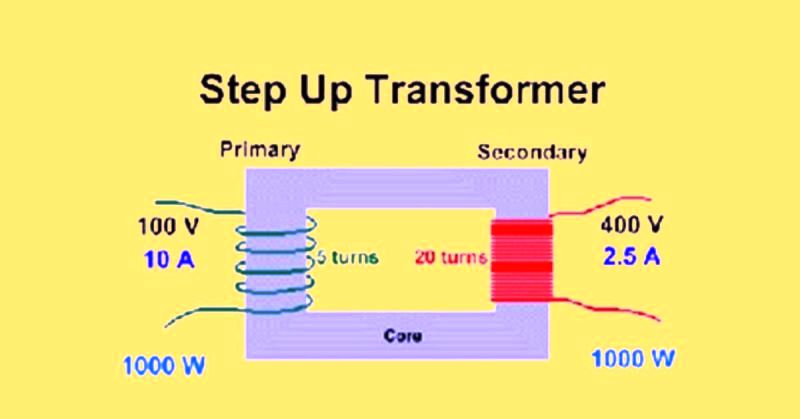

The operation of a step-up transformer is based on the principle of electromagnetic induction. It consists of two main windings: the primary winding and the secondary winding, both wound around a common magnetic core. Here’s how it works:

- Primary Winding: The primary winding is connected to the input voltage source. When an alternating current (AC) flows through this winding, it creates a varying magnetic field around the core.

- Magnetic Core: The magnetic core, usually made of laminated iron, serves to efficiently transfer the magnetic field created by the primary winding to the secondary winding. The core enhances the magnetic coupling between the windings.

- Secondary Winding: The secondary winding is connected to the output load. As the magnetic field from the primary winding changes, it induces a voltage in the secondary winding according to Faraday’s Law of Electromagnetic Induction.

What Causes More Voltage to Be Induced in a Step-Up Transformer?

The increased voltage in a step-up transformer is primarily caused by the difference in the number of turns between the primary and secondary windings. Here’s how it works:

- Turns Ratio: In a step-up transformer, the secondary winding has more turns of wire compared to the primary winding. According to Faraday’s Law of Electromagnetic Induction, the induced voltage in the windings is directly proportional to the number of turns. More turns in the secondary winding result in a higher voltage being induced compared to the primary side.

- Magnetic Flux: As the alternating current (AC) flows through the primary winding, it creates a changing magnetic field in the transformer’s core. This magnetic flux induces a voltage in both the primary and secondary windings. The greater the number of turns in the secondary winding, the greater the induced voltage.

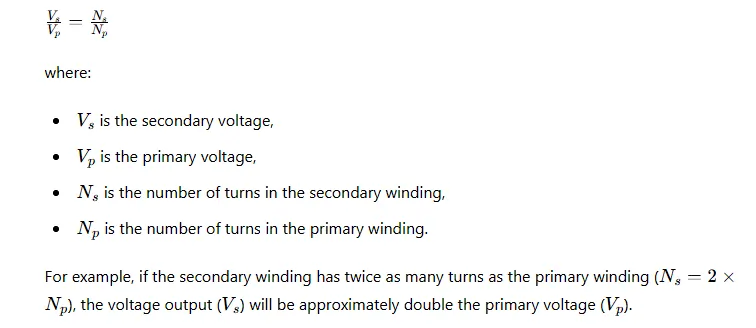

The voltage induced in the secondary winding depends on the turns ratio between the primary and secondary windings. In a step-up transformer, the number of turns in the secondary winding is greater than in the primary winding. This turns ratio determines the magnitude of the voltage increase. The relationship between the primary and secondary voltages is given by the formula:

Key Applications in Various Industries

Power Generation and Transmission

Role in Enhancing Efficiency and Reliability

Step-up transformers play a pivotal role in the power generation and transmission process by significantly enhancing the efficiency and reliability of electrical power delivery. In power plants, electricity is typically generated at relatively low voltages. However, transmitting this low-voltage power over long distances would result in substantial energy losses due to the resistance of the transmission lines. Step-up transformers are employed to increase the voltage to much higher levels, often in the range of hundreds of kilovolts, before the electricity is transmitted through the power grid.

This voltage boost reduces the current flowing through the transmission lines, which in turn minimizes resistive losses according to the formula P=I2RP = I^2RP=I2R, where PPP is the power loss, III is the current, and RRR is the resistance. By keeping the current low and the voltage high, step-up transformers ensure that the power is delivered more efficiently and with greater reliability over long distances.

Specific Examples

Renewable Energy Systems

- Wind Farms:

- In wind farms, electricity is generated by wind turbines at medium voltage levels. Step-up transformers are used to increase this voltage to a higher level suitable for transmission to the power grid. Each wind turbine typically has a dedicated step-up transformer to handle the voltage conversion before the electricity is fed into the main transmission lines.

- Solar Power Plants:

- Similar to wind farms, solar power plants generate electricity at lower voltages. Step-up transformers are crucial in these systems to elevate the voltage of the direct current (DC) generated by the solar panels to alternating current (AC) suitable for grid transmission. This process not only facilitates the efficient transfer of power but also integrates the renewable energy generated into the existing electrical grid seamlessly.

Industrial and Commercial Applications

- Manufacturing Plants:

- Large manufacturing plants often require high-voltage power for operating heavy machinery and equipment. Step-up transformers are used within these facilities to convert the lower utility voltage to the higher voltage levels required by industrial machinery. This ensures the efficient operation of equipment, reducing energy consumption and operational costs.

- Commercial Buildings:

- In commercial buildings, step-up transformers are used to supply high-voltage power for specific applications such as elevators, HVAC systems, and large-scale lighting systems. By stepping up the voltage, these transformers help in managing the electrical load more efficiently, leading to lower energy bills and enhanced reliability of power supply.

- Data Centers:

- Data centers, which house vast amounts of servers and networking equipment, rely on a steady and efficient power supply. Step-up transformers are used to ensure that these centers receive high-voltage power, which is then stepped down to the required levels for server racks and other equipment. This dual-stage voltage management helps in optimizing power distribution and reducing losses, ensuring the reliability and uptime of critical data infrastructure.

Marine Applications

- Shipboard Power Systems:

- In marine vessels, step-up transformers are essential for managing the power distribution from generators to various onboard systems. Ships generate power at lower voltages but require higher voltages for propulsion systems and other high-power applications. Step-up transformers ensure that the generated power is efficiently transmitted to these critical systems.

- Offshore Platforms:

- Offshore oil and gas platforms, as well as wind energy installations, rely on step-up transformers to manage power distribution. These platforms generate power at low voltages but need to transmit it over significant distances to shore-based facilities. Step-up transformers boost the voltage, minimizing transmission losses and ensuring reliable power delivery to and from the offshore installations.

Technical Specifications and Types

| Aspect | Description |

|---|---|

| Technical Specifications | Voltage Levels |

| Step-up transformers can handle a wide range of voltage levels, from low (110V) to high (500kV). | |

| Power Ratings | |

| Power ratings can vary from a few kilowatts (kW) to several hundred megawatts (MW). | |

| Efficiency Metrics | |

| Modern step-up transformers typically have efficiencies between 95% to 99%. | |

| Efficiency depends on factors such as core material, winding quality, and cooling methods. | |

| Different Types | Core-Type Transformers |

| Feature windings placed around a laminated iron core. | |

| Suitable for high voltage and high-power applications. | |

| Shell-Type Transformers | |

| Windings are enclosed by the core. | |

| Provide better short-circuit strength and are often used in industrial applications. | |

| Autotransformers | |

| Have a single winding that acts as both primary and secondary. | |

| More efficient and compact, suitable for applications with small voltage differences. | |

| Examples of Popular Types | Power Transformers |

| Used in power generation stations and transmission substations. | |

| Feature high efficiency and capacity for large power transfers. | |

| Distribution Transformers | |

| Used to distribute electricity to end-users at various voltage levels. | |

| Typically smaller and more widely distributed than power transformers. | |

| Instrument Transformers | |

| Include current and voltage transformers used for measurement and protection. | |

| Provide accurate readings for monitoring and control systems. | |

| Isolation Transformers | |

| Designed to decouple two circuits for safety and noise reduction. | |

| Often used in sensitive equipment and medical devices. |

Detailed Descriptions

Technical Specifications

- Voltage Levels: Step-up transformers are capable of handling a broad spectrum of voltage levels, ranging from low voltages like 110V to very high voltages up to 500kV or more. The exact voltage level depends on the specific application and requirements.

- Power Ratings: These transformers can support a variety of power ratings. Small step-up transformers may handle a few kilowatts (kW), while large industrial and utility transformers can manage several hundred megawatts (MW). The power rating determines the transformer’s ability to handle electrical load without overheating or becoming inefficient.

- Efficiency Metrics: Modern step-up transformers are designed to achieve high efficiency, typically ranging from 95% to 99%. Efficiency is crucial for minimizing energy losses during voltage conversion and transmission. Factors influencing efficiency include the quality of core materials, winding construction, and the cooling systems used to manage heat dissipation.

Different Types

- Core-Type Transformers: These transformers have windings that are placed around a laminated iron core, which provides a path for the magnetic flux. They are suitable for high voltage and high-power applications due to their robust design and ability to handle large electrical loads.

- Shell-Type Transformers: In shell-type transformers, the windings are enclosed by the core, providing better protection against short circuits and mechanical stresses. They are commonly used in industrial applications where durability and reliability are paramount.

- Autotransformers: Autotransformers feature a single winding that serves as both the primary and secondary winding. They are more efficient and compact compared to conventional transformers and are ideal for applications where the voltage difference between input and output is small.

Examples of Popular Types

- Power Transformers: These transformers are primarily used in power generation stations and transmission substations. They are designed to transfer large amounts of electrical power at high voltages, ensuring efficient long-distance transmission with minimal energy loss.

- Distribution Transformers: Used to distribute electricity from transmission lines to end-users, distribution transformers operate at lower voltage levels compared to power transformers. They are smaller in size and are widely deployed to provide electricity to residential, commercial, and industrial users.

- Instrument Transformers: Instrument transformers, including current and voltage transformers, are used for measurement and protection purposes in electrical systems. They provide accurate readings for monitoring and control, ensuring the safety and efficiency of electrical operations.

- Isolation Transformers: These transformers are designed to isolate two circuits from each other, providing safety and reducing electrical noise. They are commonly used in sensitive equipment, medical devices, and applications where clean and stable power is essential.

Installation and Best Practices

Installation Guidelines

| Step | Description |

|---|---|

| 1. Site Selection | Choose a suitable location with adequate space, ventilation, and minimal exposure to moisture and contaminants. |

| 2. Foundation Preparation | Ensure a strong, level foundation that can support the weight of the transformer. Use vibration-damping materials if necessary. |

| 3. Transformer Placement | Carefully position the transformer on the foundation. Use lifting equipment as needed to avoid damage. |

| 4. Grounding | Connect the transformer’s grounding terminal to the earth ground to ensure safety and protection against electrical faults. |

| 5. Primary and Secondary Connections | Connect the primary winding to the power source and the secondary winding to the load. Ensure proper insulation and secure connections. |

| 6. Cooling System Setup | Install and connect the cooling system (e.g., oil coolers, fans) to prevent overheating during operation. |

| 7. Protection Devices | Install protective devices such as circuit breakers, fuses, and surge protectors to safeguard against electrical faults. |

| 8. Testing | Perform initial testing, including insulation resistance, continuity, and ratio tests, to verify correct installation. |

| 9. Commissioning | Gradually energize the transformer and monitor its performance to ensure it is operating correctly. |

| 10. Documentation | Keep detailed records of the installation process, including test results and settings for future reference. |

Best Practices

| Aspect | Description |

|---|---|

| Regular Maintenance | Schedule regular inspections and maintenance to identify and address issues early. Includes checking oil levels, cooling systems, and connections. |

| Load Management | Ensure the transformer is not overloaded. Use load management practices to distribute the electrical load evenly. |

| Temperature Monitoring | Install temperature sensors to continuously monitor the transformer’s operating temperature and prevent overheating. |

| Oil Quality Checks | For oil-cooled transformers, regularly check and replace the insulating oil to maintain dielectric strength and cooling efficiency. |

| Cleaning | Keep the transformer and surrounding area clean from dust, dirt, and debris to prevent insulation degradation and overheating. |

| Safety Protocols | Implement strict safety protocols, including proper signage, personal protective equipment (PPE), and emergency procedures. |

| Vibration Monitoring | Monitor and minimize vibration levels to prevent mechanical stress and potential damage to the transformer. |

| Training | Ensure that personnel involved in the operation and maintenance of the transformer are adequately trained and certified. |

| Documentation Updates | Regularly update documentation with maintenance records, test results, and any modifications made to the transformer. |

Advantages and Benefits

Key Benefits

| Benefit | Description |

|---|---|

| Voltage Boosting | Step-up transformers increase voltage levels, making power transmission over long distances more efficient and cost-effective. |

| Reduced Energy Losses | By increasing the voltage and reducing the current, step-up transformers minimize resistive losses in transmission lines. |

| Enhanced Power Quality | They help maintain stable voltage levels, improving the overall quality and reliability of the power supply. |

| Scalability | Step-up transformers can be designed to handle various voltage levels and power ratings, making them adaptable to different applications. |

| Improved Grid Efficiency | They support the integration of renewable energy sources into the grid, enhancing overall efficiency and sustainability. |

| Safety and Protection | Equipped with protective devices, step-up transformers ensure safety and protect electrical systems from faults and surges. |

Comparative Analysis

| Aspect | Step-Up Transformers | Other Transformer Types |

|---|---|---|

| Voltage Conversion | Increase voltage levels for efficient transmission. | Step-down transformers decrease voltage for end-user safety. |

| Efficiency | High efficiency (95%-99%) in reducing transmission losses. | Similar efficiency, but tailored for different applications. |

| Application | Used primarily in power generation and transmission systems. | Used in various applications, including distribution and isolation. |

| Cost-Effectiveness | Reduces overall transmission costs by minimizing energy losses. | Other types focus on different cost-saving aspects. |

| Integration with Renewable Energy | Essential for integrating renewable energy sources like wind and solar power. | Used for distribution but less critical in renewable integration. |

| Adaptability | Can be designed for a wide range of voltage levels and power ratings. | Each type of transformer is specialized for specific uses. |

Maintenance and Troubleshooting

Maintenance Tips

| Tip | Description |

|---|---|

| Regular Visual Inspections | Conduct routine visual inspections to check for signs of wear, corrosion, oil leaks, and physical damage. |

| Oil Level and Quality Checks | Regularly monitor and maintain the oil level and quality in oil-cooled transformers to ensure effective cooling. |

| Cleaning and Debris Removal | Keep the transformer and its surroundings clean from dust, dirt, and debris to prevent overheating and insulation degradation. |

| Cooling System Maintenance | Inspect and service cooling systems, including fans, radiators, and oil coolers, to ensure proper heat dissipation. |

| Tightening Connections | Regularly tighten electrical connections to prevent arcing and overheating due to loose connections. |

| Vibration Monitoring | Monitor and mitigate vibration levels to avoid mechanical stress and potential damage to the transformer. |

| Testing and Calibration | Perform regular electrical tests, such as insulation resistance and transformer turns ratio (TTR) tests, to ensure proper functioning. |

| Protective Device Checks | Test and maintain protective devices like circuit breakers and surge protectors to ensure they operate correctly during faults. |

| Temperature Monitoring | Install temperature sensors and monitor transformer temperatures to prevent overheating and ensure efficient operation. |

Common Issues and Solutions

| Issue | Description | Solution |

|---|---|---|

| Overheating | Excessive temperature rise due to high load, inadequate cooling, or environmental factors. | Ensure proper ventilation, check and maintain cooling systems, and reduce load if necessary. |

| Oil Leaks | Oil leaks from gaskets, seals, or fittings in oil-cooled transformers. | Inspect and replace damaged gaskets and seals, tighten fittings, and maintain proper oil levels. |

| Loose Connections | Loose electrical connections causing arcing, overheating, and potential failures. | Regularly tighten connections, use lock washers or thread-locking compounds to secure fasteners. |

| Vibration and Noise | Excessive vibration and noise indicating potential mechanical issues or loose components. | Monitor vibration levels, secure loose components, and use vibration-damping materials if needed. |

| Insulation Degradation | Insulation breakdown due to aging, contamination, or excessive heat. | Perform regular insulation resistance tests, clean and replace degraded insulation materials. |

| Cooling System Failures | Malfunctioning fans, radiators, or oil coolers reducing cooling efficiency. | Inspect and service cooling systems, replace faulty components, and ensure adequate airflow. |

| Electrical Faults | Short circuits, ground faults, or open circuits within the transformer windings. | Conduct electrical tests to identify faults, repair or replace damaged windings, and ensure proper insulation. |

| Protective Device Malfunctions | Failure of circuit breakers, fuses, or surge protectors to operate during faults. | Test and maintain protective devices, replace faulty components, and ensure proper settings and calibration. |

FAQ on “Step Up Transformer”

Q: What is the primary function of a step-up transformer?

A: To increase voltage levels.

Q: How does a step-up transformer improve power transmission efficiency?

A: By minimizing resistive losses.

Q: Where are step-up transformers commonly used?

A: In power plants and renewable energy systems.

Q: What are key maintenance practices for step-up transformers?

A: Regular inspections and oil quality checks.

Conclusion

In summary, step-up transformers are indispensable components in the modern electrical landscape, playing a crucial role in enhancing the efficiency and reliability of power transmission across various industries. By boosting voltage levels, they ensure the efficient delivery of electricity over long distances, integrate renewable energy sources seamlessly into the grid, and support the robust operation of industrial, commercial, and marine applications. Adhering to best practices in installation, maintenance, and troubleshooting further enhances their performance and longevity. Embracing these powerful devices not only optimizes energy use but also paves the way for a more sustainable and efficient future.