Stuffing Box

A stuffing box plays a crucial role in sealing rotating or reciprocating shafts, preventing fluid leaks that could otherwise lead to mechanical damage. It’s an essential component in marine engines and industrial machinery, ensuring smooth operations by controlling fluid leakage around the moving shafts. In marine environments, where water, oil, and other fluids need to be sealed off, a properly installed stuffing box is vital for efficient performance and longevity of equipment.

This tutorial will provide a detailed guide to the stuffing box process, from selecting packing materials to understanding and adjusting the clearances. We will also cover the key components involved in installation and explain how to maintain and troubleshoot common issues. With this comprehensive information, you’ll learn everything you need to know for optimal stuffing box performance in 2024.

What is a Stuffing Box?

A stuffing box is a sealing device used to prevent fluid leakage along a rotating or reciprocating shaft in machinery. Its primary purpose is to ensure that fluids, such as water or oil, stay contained within a system while still allowing the shaft to move smoothly. Stuffing boxes are vital in various applications, especially in marine engines and industrial machinery, where maintaining a reliable seal is crucial for proper operation.

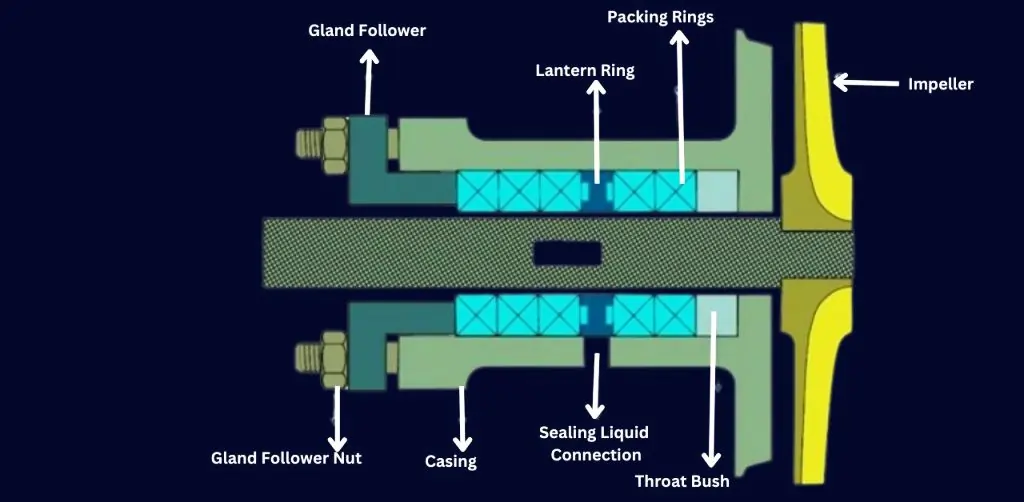

Components of a Stuffing Box:

- Gland: A component that compresses the packing material around the shaft to create a seal.

- Packing Material: Soft rings, usually made of graphite, PTFE, or fibers, that are layered inside the stuffing box to block leaks.

- Shaft: The rotating or reciprocating element passing through the stuffing box.

- Sleeve: A protective barrier placed over the shaft to prevent wear and corrosion.

Types of Stuffing Boxes:

- Mechanical: Uses mechanical seals for enhanced sealing performance.

- Braided: Made from braided fibers to provide a flexible and durable seal.

- Rubber: Utilizes rubber seals for applications requiring greater flexibility.

The Stuffing Box Process: Step-by-Step Explanation

Step 1: Preparing the Stuffing Box for Installation

Begin by thoroughly inspecting the stuffing box components, including the gland, sleeve, and shaft. Look for any signs of wear, damage, or corrosion. If any part is compromised, it should be replaced or repaired before proceeding to ensure an effective seal.

Step 2: Selecting the Appropriate Packing Material

Choosing the correct packing material is crucial for the stuffing box’s performance. Common materials include:

- Graphite: Excellent for high temperatures and pressures.

- PTFE: Suitable for chemical resistance.

- Natural Fibers: Ideal for lower temperature applications. Select a material that matches the operating conditions of your system.

Step 3: Layering the Packing Material

Carefully cut the packing rings to size and insert them into the stuffing box. Ensure staggered joints between layers to minimize leakage. Place the rings one by one, ensuring they are tightly packed.

Step 4: Tightening the Gland Nut

Tighten the gland nut carefully, ensuring even pressure across all packing layers. Avoid over-tightening, as this could damage the packing or shaft, leading to premature wear. Adjust the pressure gradually to achieve an effective seal.

Clearances in Stuffing Box Installation

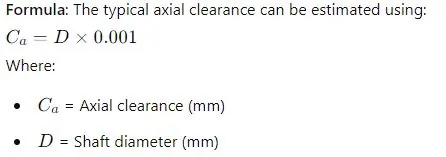

Axial Clearance

Axial clearance refers to the gap between the packing material and the shaft in the axial direction, crucial for allowing smooth shaft movement without excessive friction or wear. Insufficient clearance can cause overheating, while excessive clearance leads to leakage.

Recommended Values: For marine and industrial applications, typical axial clearance values range from 0.05 mm to 0.1 mm, depending on the equipment size and operating conditions.

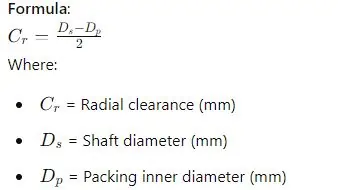

Radial Clearance

Radial clearance is the distance between the shaft and the packing material’s inner surface. Proper radial clearance ensures the shaft can move smoothly, maintaining an effective seal.

- Recommended Values: Typical radial clearance values range from 0.2 mm to 0.4 mm. Incorrect clearances can cause leakage or increased wear.

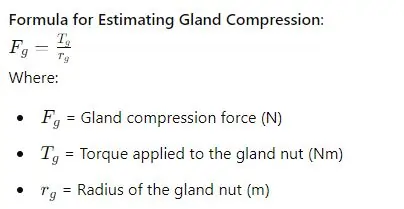

Gland Tightening Clearance

Gland tightening clearance is essential during the adjustment of the gland nut to maintain uniform packing compression without over-tightening.

Guidelines: The gland nut should be tightened gradually, ensuring uniform compression of the packing material. Monitoring torque is critical to avoid over-compression, which could damage the packing and shaft.

Common Issues and Troubleshooting with Stuffing Boxes

| Issue | Causes | Troubleshooting Steps |

|---|---|---|

| Leakage Problems | – Worn or damaged packing material – Misalignment of the shaft – Improper axial or radial clearance | 1. Inspect packing for wear and replace if necessary. 2. Realign the shaft. 3. Adjust axial and radial clearances based on recommended values. |

| Excessive Heat Generation | – Excessive friction due to over-tightening – Incorrect clearances causing packing to over-compress | 1. Loosen gland nut to reduce friction. 2. Apply proper lubrication to reduce heat. 3. Re-adjust clearances to minimize compression and friction. |

| Excessive Shaft Wear | – Incorrect or abrasive packing material – Improper radial clearance leading to shaft contact with packing | 1. Replace packing with material suited for the application. 2. Measure and adjust radial clearance to prevent shaft contact with the packing. 3. Conduct regular inspections to detect wear early. |

Maintenance Tips for Long-Lasting Stuffing Boxes

Proper maintenance of stuffing boxes is essential to ensure efficient performance and extend the lifespan of both the packing material and the shaft. Here are the key maintenance tips to follow:

1. Regular Inspection Schedule

- Establish a routine inspection schedule to monitor the condition of key stuffing box components, including the gland, packing material, and shaft.

- Inspections should be carried out at regular intervals depending on the operating conditions, typically every 3-6 months in marine and industrial applications.

- Look for signs of wear, leakage, or excessive friction, and address any issues immediately to avoid further damage.

2. Best Practices for Replacing Packing Materials

- When replacing packing materials, ensure that the old packing is completely removed before installing new rings.

- Select packing materials suited to the system’s operational conditions, such as graphite for high temperatures or PTFE for chemical resistance.

- Cut packing rings to the appropriate size, ensuring proper joint staggering to prevent leaks.

- Replace packing whenever signs of excessive wear or leakage are evident, or during scheduled maintenance.

3. Maintaining Proper Clearances

- Always maintain the recommended axial and radial clearances during installation and re-tightening. This ensures smooth operation without excessive friction or leakage.

- Avoid over-tightening the gland nut, as this can deform the packing and damage the shaft. Tighten gradually to apply even pressure.

- After re-tightening, monitor the system for any signs of leakage or friction and adjust clearances as needed to ensure optimal performance.

Summary & Key Takeaways

In summary, the stuffing box is a critical component for sealing rotating or reciprocating shafts, especially in marine and industrial applications. Following the correct installation process—from selecting the appropriate packing material to ensuring precise axial and radial clearances—plays a vital role in achieving an effective seal and preventing leaks. Improper clearances or over-tightening can lead to friction, excessive wear, and performance issues.

Regular maintenance is essential to keep stuffing boxes in optimal condition. By conducting routine inspections, replacing worn packing material, and carefully monitoring clearances, you can prevent costly breakdowns and extend the lifespan of both the stuffing box and the equipment it supports.

By following these installation and maintenance guidelines, you can maximize the efficiency, reliability, and longevity of stuffing boxes, ensuring smooth operations and avoiding unnecessary downtime.

FAQ on Stuffing Box

Q- What materials are used in stuffing boxes?

A- Graphite, PTFE, natural fibers, and other materials depending on the application.

Q- How often should the packing be replaced?

A- It depends on the application, but generally during scheduled maintenance or when signs of wear appear.

Q- What causes leakage in stuffing boxes?

A- Leakage is often caused by worn packing, shaft misalignment, or improper axial and radial clearances.

Q- How can I prevent excessive shaft wear in stuffing boxes?

A- Regular inspections, using the correct packing material, and maintaining proper clearances can prevent shaft wear and prolong the life of the stuffing box