Stuffing Box 2-Stroke Diesel Engine

Introduction

Stuffing Box 2-Stroke engines are renowned for their reliability and efficiency in the marine industry, but maintaining optimal sealing between crankcase and scavenge space remains critical for safe operation. The stuffing box is a precision-engineered component that prevents crankcase oil from entering the scavenge area, minimizing oil consumption, emissions, and liner wear. In every MAN B&W 2-stroke engine, the stuffing box uses segmented scraper rings and effective drainage to ensure oil stays where it belongs. Understanding its function, design, and common troubleshooting steps helps marine engineers extend service intervals and remain compliant with strict environmental regulations.

What is a Stuffing Box? (Marine Engine Definition)

A stuffing box is a mechanical sealing arrangement found at the lower end of the piston rod, between the engine’s crankcase and the crosshead guide space. Its primary function is to:

- Prevent scavenging air and combustion products from increasing crankcase pressure or contaminating the oil.

- Stop lube oil from entering the scavenge space or combustion chamber.

- Control oil consumption, stopping excessive oil from being drawn up the piston rod.

You may love to read our amazing post on :Stuffing Box: The Best Tutorial Of 2024

Construction & Working Principle of Stuffing Box (MAN B&W 2-Stroke)

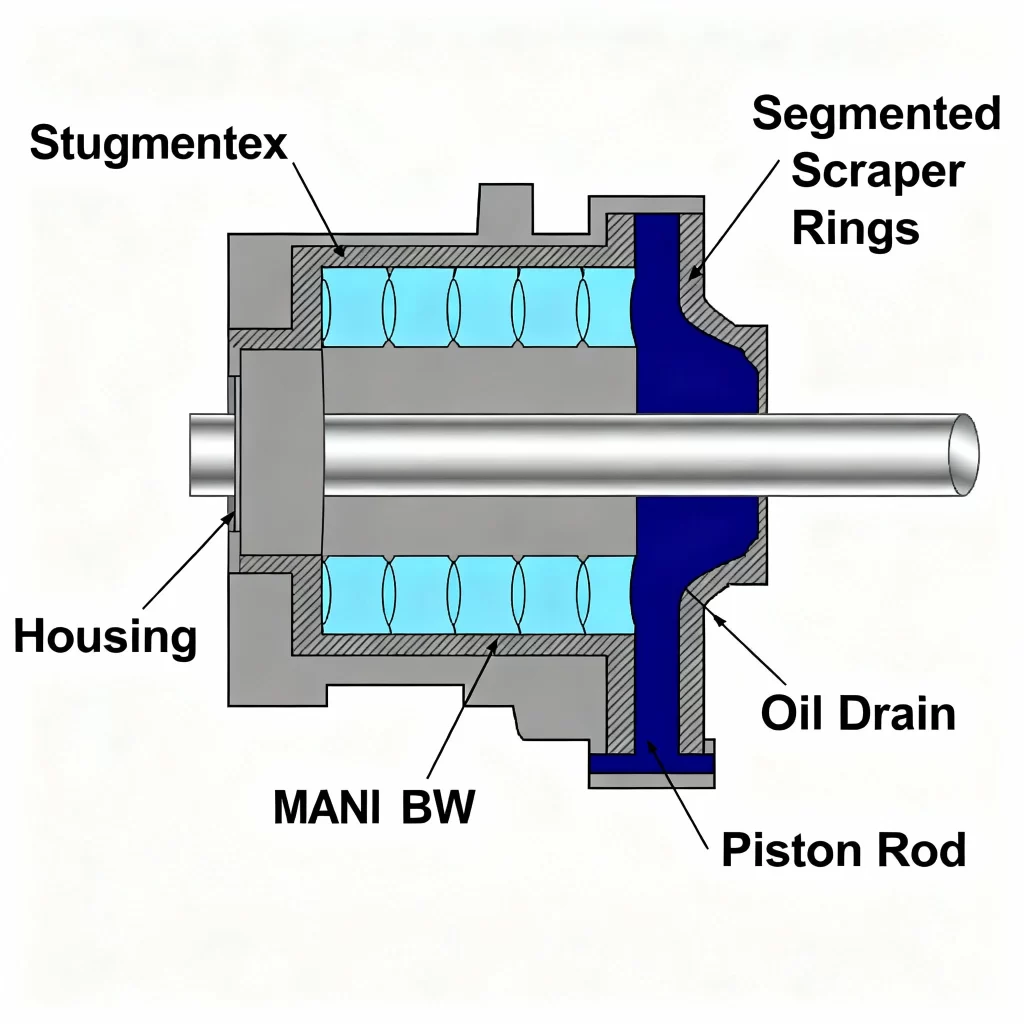

Stuffing Box Diagram: Key Components Explained

- Piston Rod:

The hardened steel shaft that transfers power from the piston to the crosshead. It reciprocates through the stuffing box, requiring effective sealing to prevent oil migration. - Segmented Scraper Rings (Upper/Lower):

Multiple metallic rings arranged in grooves within the stuffing box. Their beveled and split design allows them to flex and maintain contact with the piston rod. Rings scrape off excess oil as the rod moves. - Stuffing Box Housing:

The main cylindrical body bolted to the engine frame. It houses the scraper rings and provides the structure for the oil drain passages. - Spring Assemblies/Retainers:

Provide the necessary force to keep scraper rings firmly in contact with the moving rod, accommodating for wear and thermal expansion. - Oil Drain Passage:

Channels/cavities leading from the lower portion of the box back to the crankcase. They return collected oil, preventing it from entering the scavenge space. - Oil Groove/Collection Space:

An annular groove within the housing to gather oil collected by the lowest ring before it returns to the crankcase. - Vent/Leak Detection Port:

Opening(s) allowing inspection, oil sampling, and occasionally early warning of excessive leakage or ring failure. - Mounting Bolts/Flange:

Secure the stuffing box to the engine structure and provide alignment for easy overhaul or replacement. Ensure an oil-tight fit.

Why Does the Stuffing Box Matter?

- Environmental protection: Reduces lube oil consumption and prevents contamination of air and water by engine oil.

- Engine reliability: Keeps piston rod free from abrasives/carbon, lowering liner and ring wear.

- Safety and compliance: Critical for meeting MARPOL and class society requirements on crankcase ventilation and emissions.

| Issue | Probable Cause | Action/Remedy |

|---|---|---|

| Oil in scavenge drain | Worn/broken rings, poor tension | Inspect/replace scraper rings |

| High oil consumption | Worn rings, blocked drain passage | Clean/replace rings & passages |

| Piston rod scoring | Hard debris, failed scraper ring | Check ring material, clean/replace |

| Oil leakage at box/flange | Faulty gasket, misalignment | Renew gasket, re-align box |

| No oil at drain (unusually dry) | Stuck rings, lack of rod lubrication | Free rings, check lube system |

| White/blue smoke in exhaust | Oil entering combustion via rod | Inspect stuffing box integrity |

| Increased crankcase pressure | Failed scraper/combination of issues | Full overhaul, check ventilation |

| Abnormal noise from stuffing box | Broken ring/spring, loose assembly | Immediate shutdown, inspect/repair |

Maintenance and Overhaul (MAN B&W Best Practices)

- Regular Inspection: Check drain oil rates, inspect condition of scraped oil.

- Wear Measurement: Monitor scraper ring gap, spring force, housing wear—replace as per prescribed intervals.

- Overhaul Intervals: Usually done during major piston overhauls; clean, measure, replace rings, and lubricate spring packings.

- Leakage Monitoring: Install sensors or regular tests to detect stuffing box leakage (compliance with UMS standards).

- OEM Guidelines: Follow MAN B&W engine manual for part numbers, torque settings, and ring tolerances.

Pro Tips for Engineers

- Always check stuffing box drains as part of scavenge and crankcase inspection routines.

- Any increase in scavenge drain oil, or oil found in scavenge drain sample bottles, is an early warning sign of stuffing box ring wear.

- Track oil consumption figures—sudden increases often mean stuffing box (or piston ring) problems.

Conclusion: The Stuffing Box—Small Component, Big Impact

The stuffing box in a MAN B&W 2-stroke marine diesel engine is a minor interface with major impacts on engine health, environmental compliance, and operating costs. Diligent inspection, routine maintenance, and rapid attention to early signs of wear will ensure optimal performance and cleaner operation—critical for modern shipping standards.

Frequently Asked Questions (FAQ)

Q1: What is the main function of the stuffing box?

A: To prevent crankcase oil from entering the scavenge space and combustion chamber, and to protect the crankcase from combustion gases and contaminants.

Q2: How often should the stuffing box be inspected?

A: Check drain oil rates and visually inspect every voyage. Complete inspection and cleaning during major overhauls or piston rod maintenance.

Q3: What are typical signs of stuffing box wear or failure?

A: Increased oil found in the scavenge drain, high crankcase oil consumption, visible oil leaks, or abnormal piston rod scoring.

Q4: Can a leaking stuffing box be repaired in situ?

A: Minor issues like clogged drain passages can sometimes be cleared, but significant ring or spring wear demands removal and replacement during scheduled maintenance.

Q5: How critical is correct ring tension and ring gap?

A: Extremely—incorrect tension leads to oil bypass or rapid wear, and inappropriate ring gap disrupts the oil scraping action, reducing sealing efficiency.