Switchgears Secrets

Did you know that switchgear, an often overlooked component of electrical systems, is crucial for ensuring the safety and efficiency of power distribution? Imagine a world without reliable electricity control; chaos would ensue. Switchgear plays a pivotal role in modern electrical systems by managing, protecting, and isolating electrical equipment, ensuring smooth and safe operation.

In this blog post, we’ll dive into seven amazing facts about switchgear that will not only broaden your understanding but also highlight its significance in various applications. From different types and essential components to its wide-ranging uses in industries, you’ll discover why switchgear is indispensable. We’ll also cover maintenance tips, key manufacturers, and the standards governing its use. Whether you’re an electrical professional, a student, or simply curious, these insights will enhance your knowledge and appreciation of switchgear’s role in powering our world.

Essential Formulas for Switchgear Design and Calculation

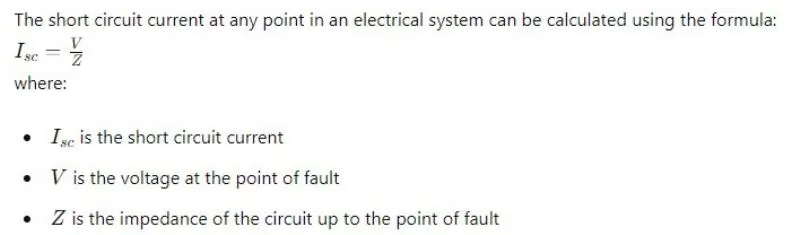

Short Circuit Current Calculation

Short circuit current is the excessive electrical current that flows through a circuit when a low-resistance path is created, bypassing the normal load. This can occur due to faults such as a direct connection between live wires or between a live wire and ground. Short circuit currents can be extremely high, leading to overheating, damage to electrical components, and potential fire hazards. Electrical protection devices like fuses and circuit breakers are designed to interrupt short circuit currents quickly to prevent damage and ensure safety.

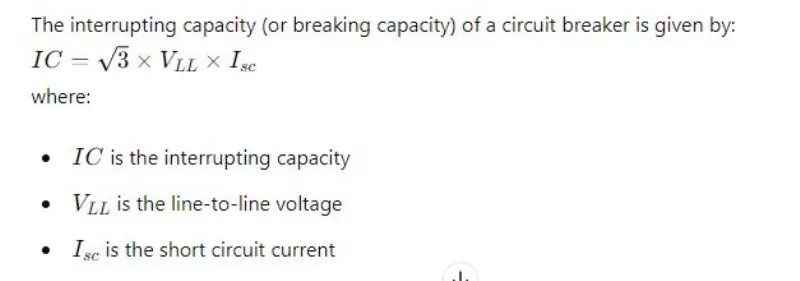

Interrupting Capacity of Circuit Breakers

Interrupting capacity, also known as breaking capacity, of circuit breakers is the maximum fault current that a circuit breaker can safely interrupt without being damaged. This specification ensures that the circuit breaker can handle severe short-circuit conditions, protecting the electrical system from excessive current. The interrupting capacity is a critical parameter for ensuring the safety and reliability of electrical installations, and it must be higher than the potential short-circuit current of the system where the breaker is installed.

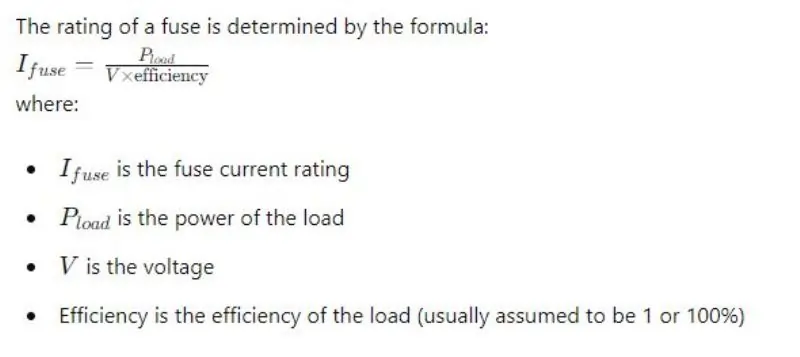

Fuse Rating Calculation

Fuse rating refers to the maximum current a fuse can carry without blowing or interrupting the circuit under normal operating conditions. It is a critical specification that ensures the fuse will protect the electrical system by breaking the circuit when the current exceeds safe levels, preventing damage or fire. The fuse rating is typically marked on the fuse and should match the requirements of the circuit it protects to ensure effective operation.

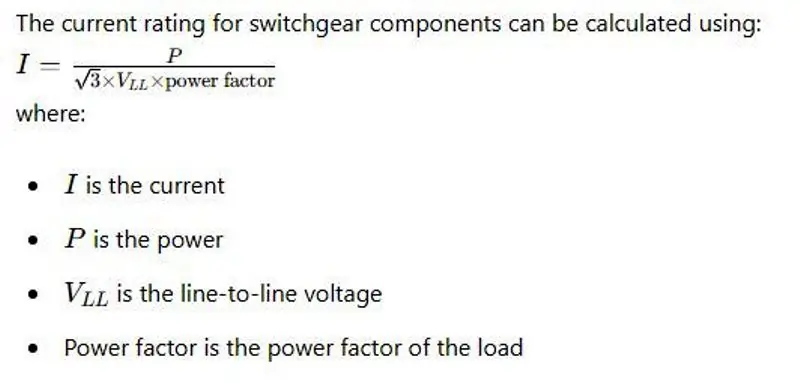

Current Rating of Switchgear

The current rating of switchgear refers to the maximum current that the switchgear can safely carry without overheating or sustaining damage under specified conditions. It is an essential parameter that ensures the switchgear can handle the electrical load of the system it protects and controls. The current rating is determined based on factors like the design, materials, and thermal performance of the switchgear components. Properly rated switchgear is crucial for maintaining the safety, reliability, and efficiency of electrical systems.

Energy Dissipation in Fuses

Energy dissipation in fuses refers to the energy that is absorbed and converted into heat when a fuse operates to interrupt an overcurrent condition. When the current exceeds the fuse’s rated capacity, the fuse element melts, breaking the circuit. The energy dissipation, often measured in joules, is the product of the current squared, the resistance of the fuse element, and the time it takes for the fuse to melt. This process protects electrical circuits by preventing excessive current from causing damage or fire.

Voltage Drop Calculation

Voltage drop refers to the reduction in voltage in an electrical circuit between the source and the load. It occurs due to the resistance or impedance of the conductors through which the current flows. Significant voltage drop can lead to inefficient operation of electrical devices, decreased performance, and potential damage to the system. Ensuring proper conductor sizing and minimizing resistance can help reduce voltage drop and maintain system efficiency.

7 The Most Amazing Facts

Fact 1: Definition and Functionality

Definition: Switchgear is an umbrella term for the assembly of switching devices, including circuit breakers, fuses, and disconnect switches, used to control, protect, and isolate electrical equipment. It functions as a key component in managing the flow of electrical power within a network, ensuring that power is distributed safely and efficiently.

Role in Electrical Systems: Switchgear serves several critical functions in electrical systems. Its primary role is to protect electrical circuits by interrupting the flow of electricity during faults, such as short circuits or overloads. This interruption prevents damage to equipment and reduces the risk of fire. Switchgear also facilitates the isolation of circuits for maintenance or emergency shutdowns, allowing for safe and controlled access to different parts of the electrical system. Additionally, it helps in managing the distribution of electrical power, ensuring that power is supplied where needed without interruptions.

Importance: For electrical professionals and enthusiasts, a thorough understanding of switchgear is indispensable. Proficiency in the functionality and components of switchgear allows for the design and maintenance of robust electrical systems. It ensures safety by enabling the prompt identification and resolution of faults, thereby protecting both personnel and equipment. Knowledge of switchgear is also vital for optimizing system performance, minimizing downtime, and ensuring compliance with industry standards and regulations. Ultimately, mastering switchgear technology is key to advancing in the field of electrical engineering and maintaining the reliability and safety of electrical power systems.

Fact 2: Types of Switchgear

| Type of Switchgear | Characteristics and Applications |

|---|---|

| High-Voltage Switchgear | Characteristics: Designed to handle voltages above 36 kV. Applications: Used in power transmission systems, substations, and large-scale industrial settings. They are essential for long-distance power transmission and large industrial plants, ensuring efficient and safe operation at high voltages. |

| Medium-Voltage Switchgear | Characteristics: Operates at voltages ranging from 1 kV to 36 kV. Applications: Commonly used in distribution systems, commercial buildings, and smaller industrial applications. It provides a balance between high-voltage transmission and low-voltage distribution, making it ideal for medium-scale power management. |

| Low-Voltage Switchgear | Characteristics: Handles voltages up to 1 kV. Applications: Used in residential, commercial, and small industrial settings. It is crucial for managing electrical distribution within buildings and small facilities, ensuring safety and reliability at lower voltage levels. |

Comparison

| Feature | High-Voltage Switchgear | Medium-Voltage Switchgear | Low-Voltage Switchgear |

|---|---|---|---|

| Voltage Range | Above 36 kV | 1 kV to 36 kV | Up to 1 kV |

| Applications | Power transmission, substations, large industries | Distribution systems, commercial buildings, smaller industries | Residential, commercial, small industries |

| Size and Complexity | Larger and more complex | Moderate in size and complexity | Smaller and simpler |

| Maintenance Requirements | High due to complexity and criticality | Moderate maintenance | Lower maintenance due to simpler design |

| Cost | Higher due to advanced technology and size | Moderate cost | Lower cost |

Fact 3: Components of Switchgear

| Component | Description |

|---|---|

| Circuit Breakers | Function: Automatically interrupt electrical flow in case of faults. Importance: Protects electrical circuits from damage due to overloads or short circuits, ensuring system safety and reliability. |

| Fuses | Role: Provide overcurrent protection by melting when exposed to excessive current. Importance: Simple and cost-effective way to protect circuits, preventing damage and fire hazards in case of overcurrent situations. |

| Disconnect Switches | Purpose: Manually isolate electrical equipment from the power supply. Operation: Operated manually or automatically to ensure safe maintenance and emergency shutdowns, preventing accidental contact with live circuits. |

| Protective Relays | Significance: Monitor electrical parameters and initiate circuit breaker operation during abnormal conditions. Importance: Essential for detecting faults and protecting electrical systems from damage, enhancing the safety and stability of power distribution networks. |

Components Comparison

| Feature | Circuit Breakers | Fuses | Disconnect Switches | Protective Relays |

|---|---|---|---|---|

| Primary Function | Interrupt electrical flow during faults | Provide overcurrent protection | Isolate electrical equipment | Monitor and detect electrical faults |

| Operation | Automatic | Melts under excessive current | Manual or automatic | Automatic |

| Importance | Critical for circuit protection | Simple and cost-effective protection | Ensures safe maintenance and emergency shutdowns | Vital for system protection and stability |

| Maintenance | Requires periodic testing and maintenance | Requires replacement after operation | Minimal maintenance | Requires periodic testing and calibration |

| Cost | Higher due to complexity | Lower cost | Moderate cost | Varies based on complexity |

Fact 4: Applications of Switchgear

| Application | Description |

|---|---|

| Power Generation | Usage: Switchgear is crucial in power plants for controlling and protecting the electrical machinery and circuits. Details: It ensures the safe operation of generators, transformers, and other equipment, managing the flow of electricity from the generation source to the grid. |

| Transmission | Role: Switchgear is used to control the high-voltage electricity flow from power plants to substations. Details: It protects the transmission lines from faults and allows for the isolation and maintenance of various sections of the transmission network. |

| Distribution Systems | Importance: Essential for managing and protecting the distribution of electrical power to end-users. Details: Switchgear ensures reliable and safe delivery of electricity to residential, commercial, and industrial consumers, facilitating load management and fault isolation. |

| Industrial Uses | Industry-Specific Applications: Switchgear is used in various industries to manage complex electrical networks. Details: It is essential in manufacturing plants, chemical plants, mining operations, and other industrial settings for ensuring operational safety and efficiency. |

Applications Comparison

| Feature | Power Generation | Transmission | Distribution Systems | Industrial Uses |

|---|---|---|---|---|

| Primary Function | Control and protect electrical machinery | Manage high-voltage electricity flow | Ensure reliable power delivery | Manage complex industrial electrical networks |

| Operation | Ensures safe generator and transformer operation | Protects transmission lines and enables maintenance | Facilitates load management and fault isolation | Ensures operational safety and efficiency |

| Importance | Critical for safe power generation | Essential for stable power transmission | Vital for end-user electricity distribution | Crucial for industry-specific applications |

| Maintenance Requirements | High due to complex systems | Moderate due to high voltage levels | Moderate to high depending on network complexity | Varies based on industry and complexity |

Fact 5: Maintenance and Safety

| Aspect | Description |

|---|---|

| Maintenance Tips | Guidelines: Regular inspections and cleaning, testing and calibration of protective devices, lubrication of moving parts, and timely replacement of worn components. Details: Ensure proper ventilation, check for signs of wear and tear, and adhere to manufacturer maintenance schedules. |

| Safety Protocols | Measures: Implement lockout/tagout procedures, use personal protective equipment (PPE), and follow proper grounding practices. Best Practices: Conduct regular safety training, keep switchgear areas clean and accessible, and perform routine safety audits. |

| Common Issues | Problems: Loose connections, insulation failures, moisture ingress, and overheating. Solutions: Tighten connections, replace faulty insulation, ensure proper sealing and humidity control, and monitor temperatures regularly to prevent overheating. |

Maintenance and Safety Comparison

| Feature | Maintenance Tips | Safety Protocols | Common Issues |

|---|---|---|---|

| Primary Focus | Regular upkeep to ensure reliability | Ensuring safe operation | Identifying and addressing frequent problems |

| Key Activities | Inspections, cleaning, testing, lubrication | Lockout/tagout, PPE use, grounding practices | Tightening connections, replacing insulation |

| Importance | Prevents unexpected failures and extends lifespan | Prevents accidents and injuries | Maintains operational efficiency and safety |

| Frequency | Periodic (monthly, quarterly, annually) | Continuous and during maintenance activities | As needed, based on inspections and performance |

| Outcome | Enhanced performance and reduced downtime | Safe working environment | Prolonged equipment life and minimized hazards |

Fact 6: Leading Manufacturers and Suppliers

| Aspect | Description |

|---|---|

| Top Manufacturers | ABB: Known for innovative and high-quality switchgear products. <br> Contact Details: Website: ABB Official Site Phone: +41 43 317 71 11 Email: contact.center@ch.abb.com Address: Affolternstrasse 44, 8050 Zurich, Switzerland Siemens: Offers a wide range of reliable and advanced switchgear solutions. Contact Details: Website: Siemens Official Site Phone: +49 89 636-00 Email: contact@siemens.com Address: Werner-von-Siemens-Strasse 1, 80333 Munich, Germany Schneider Electric: Renowned for sustainable and efficient switchgear systems. Contact Details: Website: Schneider Electric Official Site Phone: +33 1 41 29 70 00 Email: global-customer-care@se.com Address: 35 Rue Joseph Monier, 92500 Rueil-Malmaison, France Eaton: Provides durable and cost-effective switchgear options. Contact Details: Website: Eaton Official Site Phone: +1 (216) 523-5000 Email: WebSupport@Eaton.com Address: Eaton Center, 1000 Eaton Boulevard, Cleveland, OH 44122, USA General Electric (GE): Offers robust and versatile switchgear products for various applications. Contact Details: Website: GE Official Site Phone: +1 617 443 3000 Email: contact@ge.com Address: 5 Necco Street, Boston, MA 02210, USA |

| Supplier Information | Choosing the Right Supplier: Reputation: Look for suppliers with a strong track record and positive customer reviews. Product Range: Ensure the supplier offers a comprehensive range of switchgear products to meet specific needs. Quality Assurance: Verify that the supplier adheres to industry standards and provides certified products. Technical Support: Choose suppliers that offer excellent customer service and technical support. |

| Market Trends | Current Trends: Smart Switchgear: Integration of digital technologies for better monitoring and control. Eco-Friendly Solutions: Increasing demand for environmentally sustainable switchgear products. Compact Designs: Growing preference for space-saving and modular switchgear systems. Enhanced Safety Features: Focus on advanced safety mechanisms to prevent accidents and improve reliability. What to Look For: Innovation: Products with the latest technological advancements. Compliance: Ensure switchgear meets regulatory standards. Energy Efficiency: Look for energy-efficient solutions to reduce operational costs. |

Leading Manufacturers and Suppliers Comparison

| Feature | Top Manufacturers | Supplier Information | Market Trends |

|---|---|---|---|

| Primary Focus | Providing high-quality and reliable products | Ensuring the selection of reputable suppliers | Identifying and adapting to market changes |

| Key Aspects | Innovation, reliability, sustainability | Reputation, product range, quality assurance | Smart technology, eco-friendliness, compact design, safety features |

| Importance | Ensures availability of top-tier switchgear | Guarantees reliable and suitable products | Staying updated with market demands and advancements |

| Selection Criteria | Industry reputation, product offerings | Strong track record, customer reviews, standards adherence | Technological innovation, regulatory compliance, energy efficiency |

| Outcome | Access to top-performing switchgear solutions | Optimal supplier choice for specific needs | Up-to-date and future-ready switchgear solutions |

Fact 7: Standards and Regulations

| Aspect | Description |

|---|---|

| Key Standards | IEC (International Electrotechnical Commission): Provides international standards for electrical, electronic, and related technologies, including switchgear (e.g., IEC 62271). IEEE (Institute of Electrical and Electronics Engineers): Develops global standards for electrical and electronic technologies, including switchgear specifications (e.g., IEEE C37 series). ANSI (American National Standards Institute): Establishes U.S. standards for various industries, including switchgear (e.g., ANSI C37). NEMA (National Electrical Manufacturers Association): Publishes standards for electrical equipment and components, including switchgear (e.g., NEMA SG 4). |

| Regulatory Compliance | Importance: Ensures that switchgear meets minimum safety, performance, and quality criteria. Details: Adherence to standards is crucial for certification, legal compliance, and market acceptance. It also helps in avoiding fines, legal issues, and ensuring reliable and safe operations. |

| Impact on Quality and Safety | Quality Assurance: Standards ensure that switchgear products are manufactured to consistent quality levels, enhancing reliability and performance. Safety Measures: Compliance with standards ensures that switchgear is designed and tested to prevent electrical hazards, protecting both equipment and personnel. Global Compatibility: Adhering to international standards ensures compatibility and interoperability of switchgear products in different regions and markets. |

Standards and Regulations Comparison

| Feature | Key Standards | Regulatory Compliance | Impact on Quality and Safety |

|---|---|---|---|

| Primary Focus | Establishing guidelines and specifications | Ensuring adherence to established standards | Enhancing product quality and safety |

| Key Aspects | IEC, IEEE, ANSI, NEMA | Certification, legal compliance, market acceptance | Quality assurance, safety measures, global compatibility |

| Importance | Provides a benchmark for design and performance | Prevents legal issues and ensures reliable operation | Protects equipment and personnel from hazards |

| Outcome | Consistent and reliable switchgear products | Legal and market acceptance | High-quality, safe, and reliable switchgear |

FAQ on “Switchgear Secrets”

Q: What is switchgear?

A: Switchgear is a collection of devices used to control, protect, and isolate electrical equipment in power systems.

Q: Why is switchgear important in electrical systems?

A: Switchgear ensures safe and reliable power distribution by managing and protecting electrical circuits from faults and overloads.

Q: What are the main types of switchgear?

A: The main types are high-voltage, medium-voltage, and low-voltage switchgear, each used for different voltage levels and applications.

Q: What are some key maintenance tips for switchgear?

A: Regular inspections, testing and calibration, cleaning, and timely replacement of worn components are essential for maintaining switchgear.

Conclusion

In this blog post, we explored seven amazing facts about switchgear: its definition and functionality, types, essential components, various applications, maintenance and safety protocols, leading manufacturers and suppliers, and the crucial standards and regulations governing its use. Understanding these aspects is vital for anyone involved in electrical systems, as it ensures safe, efficient, and reliable power distribution.

Switchgear plays a pivotal role in protecting and managing electrical circuits, making it indispensable for both professionals and enthusiasts. By staying informed about the latest trends, standards, and maintenance practices, you can enhance the safety and performance of your electrical systems.

We invite you to share your experiences with switchgear, ask any questions you might have, and explore further resources to deepen your knowledge. Your insights and inquiries can help build a stronger community of informed and skilled electrical professionals.