What is Tappet Clearance

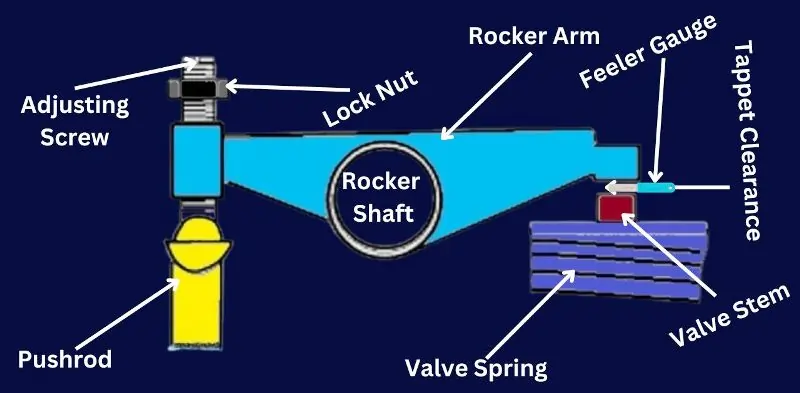

Tappet clearance is the small gap between the valve stem and rocker arm, essential for smooth engine operation. It allows for thermal expansion and ensures uniform valve opening. Exhaust valve tappet clearance is usually greater than inlet clearance to handle higher exhaust temperatures, promoting efficient valve timing and preventing damage. Maintaining proper clearance is key to optimal engine performance..

Difference Between Inlet and Exhaust Tappet Clearance

Exhaust Valve Tappet Clearance:

Exhaust valve tappet clearance is typically larger than inlet valve clearance due to the higher temperatures experienced by the exhaust gases. This additional clearance allows the exhaust valve to expand more without affecting engine timing or performance, preventing damage and ensuring efficient exhaust flow.

Inlet Valve Tappet Clearance:

The inlet valve experiences lower temperatures compared to the exhaust valve, so it requires less clearance. Proper inlet valve tappet clearance is crucial for maintaining engine efficiency, ensuring the valve opens at the correct time to allow optimal air intake for combustion.

How to Check Tappet Clearance

Pre-requisite:

Ensure that the pushrod is free, meaning both inlet and exhaust valves are closed. This occurs when the engine is at its firing Top Dead Center (TDC), which can be identified by checking the markings on the flywheel.

Check Marking on Flywheel:

Locate the correct TDC marking on the flywheel. This indicates that both the inlet and exhaust valves are fully closed, and it’s the optimal point to check tappet clearance.

Opening the Cam Case Cover:

Once the cam case cover is open, ensure that the roller is positioned on the base circle of the cam. This ensures the valves are closed, allowing for an accurate clearance measurement.

Fuel Pump Sleeve Marking:

The fuel pump has sleeve markings that indicate the timing of injection. The top mark represents the beginning of injection, while the bottom mark signals the end. Tappet clearance should ideally be checked when the engine is warm to account for thermal expansion.

Step-by-Step Check:

- Loosen the lock nut on the adjusting screw.

- Use a feeler gauge to measure the gap between the valve stem and the rocker arm.

- Ensure the tappet clearance allows for proper valve operation, accommodating thermal expansion.

- Adjust as needed by turning the adjusting screw to either increase or decrease the clearance.

- Tighten the lock nut to secure the correct clearance.

Effects of Incorrect Tappet Clearance

Clearance is Too Large:

- Hammering of Valve Stem: Excessive clearance causes the valve stem to be hammered by the rocker arm, leading to wear and potential damage over time.

- Inlet Valve Opens Late: When the clearance is too large, the inlet valve opens later than it should, decreasing blowdown efficiency. This results in a loss of power and poor combustion, reducing overall engine performance.

- Exhaust Valve Opens Later: A delayed exhaust valve opening leads to a reduction in the quality of air expelled from the engine, causing a loss of power and a smoky exhaust, indicating incomplete combustion.

Clearance is Too Small:

- Valves Open Early: If the tappet clearance is too small, the valves will open too early, leading to a loss of compression, decreased peak pressure (Pmax), and reduced engine efficiency.

- Valve Burning: Insufficient clearance causes the valves to remain partially open during combustion, leading to overheating and eventual valve burning due to excessive heat exposure. This can cause serious engine damage if not corrected.

Importance of Correct Tappet Clearance

Maintaining the correct tappet clearance is crucial for optimal engine performance and longevity. Proper clearance ensures smooth valve operation, efficient combustion, and prevents unnecessary wear on engine components like the valve stem, rocker arm, and camshaft. By allowing for thermal expansion, the engine operates without strain, ensuring peak power output and fuel efficiency.

Neglecting tappet clearance checks can lead to serious risks. Incorrect clearance, whether too large or too small, can cause issues like poor combustion, loss of power, valve damage, overheating, and even engine failure. Regular checks help avoid these problems, ensuring a long, efficient life for the engine.

Key Formulas for Valve Clearance Adjustment

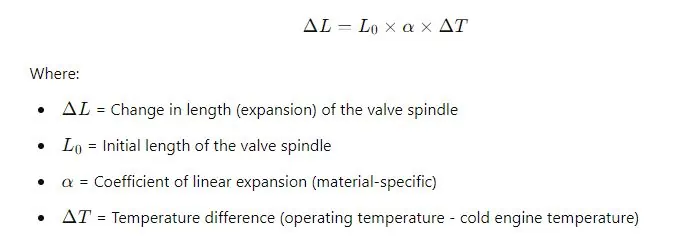

1. Thermal Expansion of Valve Spindle:

To account for thermal expansion, tappet clearance should be adjusted based on the difference in operating temperatures between the engine’s cold and hot states. The basic thermal expansion formula can be expressed as:

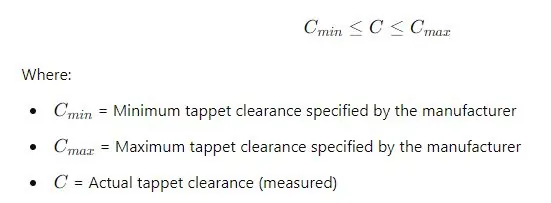

2. Correct Clearance Range Formula:

The tappet clearance should always fall within the manufacturer’s recommended range, which can be expressed as:

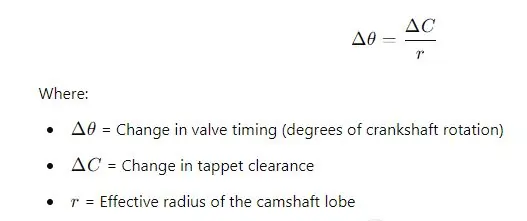

3. Valve Timing Adjustment Based on Valve Clearance

Incorrect tappet clearance can affect valve timing. The change in valve opening timing due to excess clearance can be approximated as:

4. Impact on Compression (Pmax):

Excessive tappet clearance can result in a reduction of peak cylinder pressure (Pmax). While not directly calculated from tappet clearance, the relationship can be monitored by observing:

Step-by-Step Guide to Adjust Tappet Clearance

Tools Required:

- Feeler gauge

- Wrench set

- Screwdriver

- Locking pliers

- Torque wrench (optional)

- Engine service manual for reference

Procedure to Set Correct Tappet Clearance:

- Prepare the Engine:

Ensure the engine is warm, as tappet clearance is best checked at operating temperature. Place the engine at firing Top Dead Center (TDC) on the compression stroke for the cylinder you’re adjusting. - Access the Valves:

Remove the valve cover to expose the valve components, including the rocker arms, pushrods, and valve stems. - Check the Camshaft Position:

Rotate the engine until the roller is on the base circle of the camshaft, ensuring both the inlet and exhaust valves are fully closed. - Loosen the Lock Nut:

Use a wrench to loosen the lock nut on the tappet’s adjusting screw. - Measure the Tappet Clearance:

Insert the feeler gauge between the valve stem and rocker arm. Ensure the gauge slides with slight resistance, confirming the gap matches the manufacturer’s recommended clearance. - Adjust the Clearance:

If the clearance is too large or small, turn the adjusting screw to increase or decrease the gap until the feeler gauge fits perfectly. - Tighten the Lock Nut:

Once the clearance is correct, hold the adjusting screw in place with a screwdriver and tighten the lock nut with a wrench to secure the adjustment. - Recheck the Clearance:

After tightening the lock nut, double-check the clearance with the feeler gauge to ensure the setting hasn’t shifted. - Repeat for Other Valves:

Follow the same process for all other valves on the engine. - Reassemble and Test:

Reinstall the valve cover, tighten it securely, and run the engine to ensure it operates smoothly. Listen for any unusual noises, which may indicate incorrect adjustments.

Common Mistakes to Avoid

When adjusting tappet clearance, it’s easy to make mistakes that can affect engine performance. Some common errors include:

- Not Setting the Engine at TDC:

Failing to position the engine at the correct Top Dead Center (TDC) for each cylinder can lead to inaccurate clearance adjustments. Always check markings on the flywheel or consult the manual to confirm the engine is at the proper TDC before adjusting. - Using the Wrong Feeler Gauge:

Using an incorrect size feeler gauge or not ensuring the gauge fits with slight resistance can result in incorrect clearance settings. Always select the correct gauge specified by the manufacturer. - Improper Tightening of Lock Nut:

After adjusting the clearance, failure to properly tighten the lock nut can cause the settings to shift during operation, leading to valve timing issues. Hold the adjusting screw securely and tighten the lock nut firmly. - Adjusting When the Engine is Cold:

Tappet clearance should be checked when the engine is warm to account for thermal expansion. Adjusting on a cold engine can result in incorrect clearance, affecting performance when the engine heats up. - Ignoring Manufacturer’s Specifications:

Each engine has specific clearance recommendations based on its design. Ignoring these specifications or using general values can lead to serious problems like poor combustion or valve damage. Always follow the manufacturer’s guidelines closely to avoid costly repairs.

FAQ on “What is Tappet Clearance”

Q- What is tappet clearance?

A- Tappet clearance is the gap between the valve stem and rocker arm in an engine.

Q- Why is tappet clearance important?

A- It allows for thermal expansion, ensuring smooth valve operation and preventing damage.

Q- Why is exhaust tappet clearance larger than inlet?

A- The exhaust valve experiences higher temperatures, requiring more clearance for expansion.

Q- What happens if tappet clearance is incorrect?

A- Incorrect clearance can cause poor combustion, loss of power, and valve damage.

Conclusion

In conclusion, maintaining correct tappet clearance is vital for optimal engine performance and longevity. It ensures smooth valve operation, accommodates thermal expansion, and prevents engine issues like poor combustion, power loss, and valve damage. Regularly checking and adjusting tappet clearance according to manufacturer specifications is essential to keep your engine running efficiently and reliably.