Thermistors

Thermistors are highly sensitive temperature sensors that change their resistance with temperature variations. These essential components play a critical role in achieving precise temperature measurements across a wide range of applications, from medical devices and automotive systems to consumer electronics and industrial processes. Their quick response to temperature changes and high accuracy make them invaluable in maintaining control and safety in various environments.

This article aims to provide actionable tips to enhance the precision of thermistors. By implementing these strategies, you can significantly improve the accuracy and reliability of your temperature measurements. The benefits of following these tips include better performance, increased lifespan of the sensors, and more consistent results in critical temperature-sensitive processes. Ultimately, this leads to enhanced operational efficiency and safety, ensuring that thermistors perform optimally in their specific applications. Whether you’re a professional in the field or looking to deepen your understanding, these insights will prove invaluable.

What is a Thermistor?

Definition

A thermistor is a type of temperature sensor that exhibits a significant change in resistance with variations in temperature. The term “thermistor” is derived from a combination of “thermal” and “resistor,” reflecting its function as a resistor whose resistance is influenced by temperature. These components are made from semiconductor materials, which are carefully selected to provide the desired temperature-resistance characteristics.

Sensitivity to Temperature Changes

Thermistors are renowned for their high sensitivity to temperature changes. This sensitivity allows them to detect even small variations in temperature, making them ideal for applications requiring precise temperature measurements and control. The resistance of a thermistor changes predictably with temperature, which can be measured and converted into accurate temperature readings. This high sensitivity and accuracy make thermistors essential in various applications, including medical devices, automotive systems, consumer electronics, and industrial processes. By responding quickly and accurately to temperature fluctuations, thermistors help maintain optimal performance and safety in these critical applications.

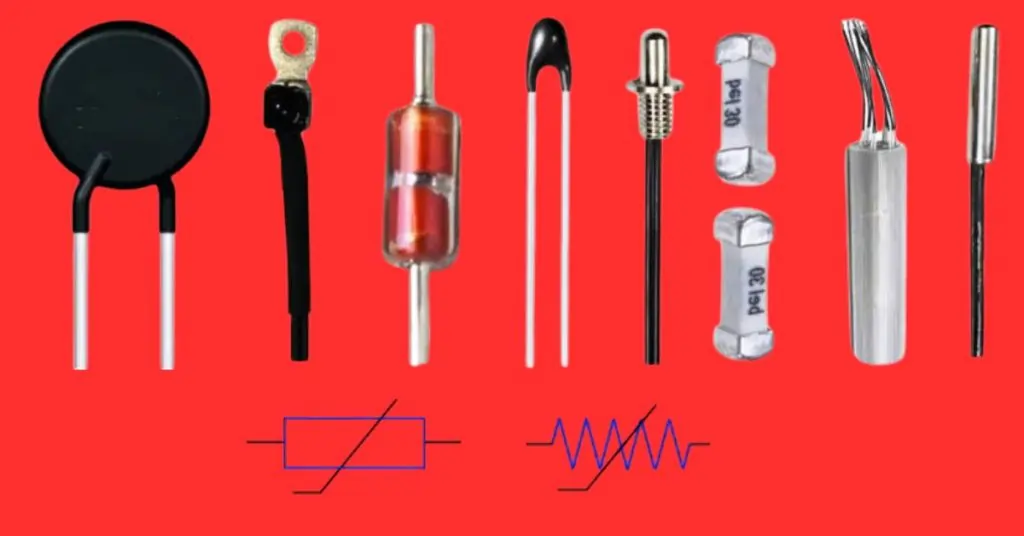

Types of Thermistors

NTC (Negative Temperature Coefficient) Thermistors

Characteristics: NTC thermistors are characterized by a decrease in resistance as temperature increases. This inverse relationship between temperature and resistance makes NTC thermistors highly sensitive to temperature changes, enabling precise temperature measurements.

Applications:

- Temperature Sensing: NTC thermistors are commonly used in applications requiring accurate temperature readings, such as digital thermometers.

- Automotive Applications: They are employed in automotive systems for monitoring engine temperature, coolant temperature, and cabin climate control.

- Consumer Electronics: NTC thermistors are used in devices like refrigerators, air conditioners, and battery packs to monitor and control temperatures.

- Medical Devices: These thermistors are also found in medical equipment where precise temperature monitoring is critical, such as in patient monitoring systems.

PTC (Positive Temperature Coefficient) Thermistors

Characteristics: PTC thermistors exhibit an increase in resistance as temperature rises. This characteristic is particularly useful for applications that require the thermistor to act as a self-regulating heating element or as a protective device against overcurrent conditions.

Applications:

- Overcurrent Protection: PTC thermistors are used in circuits to protect against overcurrent conditions. As the current increases, the thermistor’s resistance rises, reducing the current flow and preventing damage to the circuit.

- Self-Regulating Heating Elements: In applications like heaters, PTC thermistors serve as self-regulating heating elements. As the temperature of the element increases, the resistance rises, limiting the current and thus the heat generated, maintaining a consistent temperature.

- Consumer Electronics: PTC thermistors are found in power supplies and charging systems to protect against overheating and overcurrent conditions.

- Industrial Applications: In industrial settings, PTC thermistors are used in motor windings and transformers to provide thermal protection.

Working Principle

Semiconductor Behavior

Thermistors operate based on the principle that the resistance of semiconductor materials changes with temperature. The relationship between temperature and resistance in thermistors is highly predictable, making them ideal for precise temperature measurement and control. This behavior can be described by the following key points:

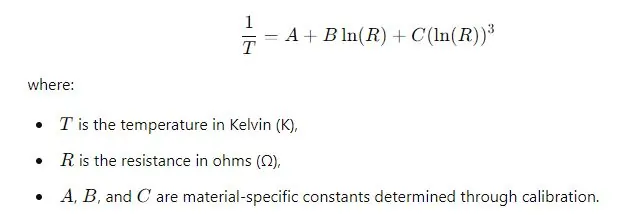

NTC Thermistors: In Negative Temperature Coefficient (NTC) thermistors, resistance decreases as temperature increases. This is due to the increase in charge carrier concentration with temperature in the semiconductor material, which allows more current to flow, thus reducing resistance. The behavior of NTC thermistors can be described by the Steinhart-Hart equation:

PTC Thermistors: In Positive Temperature Coefficient (PTC) thermistors, resistance increases as temperature increases. This happens because, at higher temperatures, the increased atomic vibrations within the material reduce the mobility of charge carriers, resulting in increased resistance. The resistance behavior of PTC thermistors can often be approximated by a simpler linear relationship in specific temperature ranges, though exact models can vary based on the material composition.

Calibration Curves

To use thermistors effectively, it is necessary to correlate their resistance with temperature. This is achieved through calibration, where resistance measurements at known temperatures are used to create a calibration curve. Here’s how this process works:

- Data Collection: Measure the resistance of the thermistor at various known temperatures. These temperatures are typically controlled using a precision temperature bath or oven.

- Plotting the Curve: Plot the measured resistance values against the corresponding temperatures to create a calibration curve. For NTC thermistors, this curve typically shows an exponential decrease in resistance with increasing temperature. For PTC thermistors, the curve shows an increase in resistance with temperature.

- Curve Fitting: Use mathematical models to fit the calibration data. For NTC thermistors, the Steinhart-Hart equation is commonly used. For PTC thermistors, simpler linear or polynomial fits might be used depending on the operating temperature range. The equations used for these fits are derived from the data points obtained during calibration.

- Using the Calibration Curve: Once the calibration curve is established, it can be used to determine the temperature from measured resistance values. This is done by solving the calibration equation for temperature given a measured resistance.

Key Features of Thermistors

High Sensitivity

Thermistors are renowned for their high sensitivity to temperature changes, which allows them to detect even small variations in temperature with remarkable accuracy. This high sensitivity is due to the exponential relationship between temperature and resistance in NTC thermistors and the significant resistance change in PTC thermistors.

For NTC thermistors, the resistance R as a function of temperature T can be described by the Steinhart-Hart equation:

This equation shows that even small changes in temperature TTT result in large changes in resistance RRR, enabling precise temperature measurement. For PTC thermistors, the resistance increases sharply with temperature after a certain threshold, which is highly useful for specific protective applications.

Temperature Range

Thermistors typically operate within a temperature range of -50°C to 150°C. This range covers a broad spectrum of applications, from very low-temperature environments to moderately high-temperature conditions. Some specialized thermistors are designed to handle temperatures beyond this typical range, providing versatility for more demanding applications.

For example, NTC thermistors might be used in cryogenic applications at very low temperatures, while high-temperature thermistors might be used in industrial processes. The ability to function accurately across such a wide range makes thermistors indispensable in many fields.

Response Time

One of the standout features of thermistors is their quick response time. This rapid response is crucial in applications where immediate temperature detection and control are necessary. The response time of a thermistor is primarily determined by its thermal mass and the medium in which it is used.

A typical thermistor can respond to temperature changes in a matter of seconds, making them ideal for applications such as:

- Medical Devices: Quick temperature readings in patient monitoring systems.

- Automotive Applications: Rapid detection of temperature changes in engine management systems.

- Consumer Electronics: Immediate response in devices like digital thermometers and climate control systems.

- Industrial Processes: Real-time temperature monitoring and control in manufacturing and processing plants.

The quick response time of thermistors ensures that they can provide timely and accurate temperature readings, which is essential for maintaining control and safety in critical applications.

Applications of Thermistors

Medical Devices

Thermistors are widely used in medical devices due to their high sensitivity and quick response time. They play a crucial role in ensuring accurate and reliable temperature measurements in various medical applications:

- Electronic Thermometers: Thermistors provide rapid and precise temperature readings, essential for patient care. The high sensitivity of thermistors ensures that even minor temperature variations are detected quickly, allowing for accurate body temperature monitoring.

- Patient Monitoring Systems: In intensive care units and other critical care settings, thermistors are integrated into patient monitoring systems to continuously track body temperature. The fast response time of thermistors ensures that any sudden changes in patient temperature are immediately detected and reported.

Automotive

In the automotive industry, thermistors are essential for maintaining optimal performance and safety. They are used in several key applications:

- Engine Temperature Monitoring: Thermistors monitor the engine’s temperature, providing real-time data to the engine control unit (ECU). This helps prevent overheating and ensures the engine operates within its optimal temperature range.

- Battery Management Systems: In electric and hybrid vehicles, thermistors are used to monitor battery temperature. Maintaining the battery within a safe temperature range is crucial for performance, longevity, and safety. The data from thermistors helps manage charging and discharging processes efficiently.

Consumer Electronics

Thermistors are integral components in various consumer electronics, ensuring the efficient and safe operation of household appliances:

- Refrigerators: Thermistors regulate the internal temperature, ensuring food is stored at the correct temperature to prevent spoilage.

- Ovens: In cooking appliances, thermistors help maintain precise cooking temperatures, enhancing cooking performance and energy efficiency.

- HVAC Systems: Thermistors are used in heating, ventilation, and air conditioning (HVAC) systems to monitor and control ambient temperature, ensuring comfort and energy efficiency.

Industrial

In industrial applications, thermistors are used for process control, temperature compensation, and environmental monitoring:

- Process Control: Thermistors are employed in manufacturing processes to monitor and control temperatures. This ensures that processes operate within specified parameters, maintaining product quality and consistency.

- Temperature Compensation: In various industrial sensors and instruments, thermistors are used to compensate for temperature variations, ensuring accurate readings across different environmental conditions.

- Environmental Monitoring: Thermistors are used in environmental monitoring systems to track temperature changes in various settings, such as warehouses, greenhouses, and data centers. This data helps maintain optimal conditions for storage, growth, and equipment operation.

Comparison with Thermocouples

| Feature | Thermistors | Thermocouples |

|---|---|---|

| Sensitivity | Thermistors exhibit high sensitivity to small temperature changes, making them ideal for precise measurements. | Thermocouples are less sensitive to small temperature changes but are reliable for a wide range of temperatures. |

| Temperature Range | Operate typically within -50°C to 150°C. Some specialized thermistors can handle broader ranges. | Can measure temperatures from -200°C to 1750°C, making them suitable for extreme temperature environments. |

| Application Suitability | Ideal for low to moderate temperature measurements where precision is crucial, such as in medical devices, consumer electronics, and automotive systems. | Suitable for high-temperature applications like industrial processes, power generation, and scientific research. |

Detailed Descriptions

Sensitivity:

- Thermistors: Due to their high sensitivity, thermistors can detect minute temperature changes. This makes them highly accurate for applications where precision is critical. Their resistance changes significantly with small temperature variations, providing detailed and precise readings.

- Thermocouples: While thermocouples are reliable, their sensitivity to small temperature changes is lower compared to thermistors. They are better suited for applications where large temperature ranges are involved, rather than detecting small temperature fluctuations.

Temperature Range:

- Thermistors: Typically, thermistors operate within a range of -50°C to 150°C. Some advanced thermistors can function beyond this range, but they are generally not used for extreme high-temperature applications.

- Thermocouples: Thermocouples can measure a much broader temperature range, from -200°C to 1750°C. This wide range makes them suitable for various industrial applications, including those involving extreme temperatures that thermistors cannot handle.

Application Suitability:

- Thermistors: Best suited for applications that require precise, low to moderate temperature measurements. Common uses include medical devices like electronic thermometers, automotive systems for engine and battery temperature monitoring, and consumer electronics such as HVAC systems and refrigerators.

- Thermocouples: Ideal for high-temperature applications where a broad range of temperature measurement is necessary. They are commonly used in industrial processes, power generation, scientific research, and environments where temperatures can vary significantly and reach extreme levels.

The Best 5 Power Tips for Ultimate Precision

| Tip | Description |

|---|---|

| Tip 1: Proper Calibration | Regularly calibrating thermistors is crucial for maintaining their accuracy. Calibration ensures that the thermistor provides precise temperature readings by compensating for any drift or changes in its characteristics over time. |

| Tip 2: Optimal Placement | Proper placement of thermistors is essential for accurate temperature measurements. Place thermistors in locations where they can accurately reflect the temperature of the medium being measured, away from heat sources or areas with airflow that can cause false readings. |

| Tip 3: Using High-Quality Materials | Choosing high-quality materials for thermistors enhances their performance and durability. High-quality materials ensure that thermistors can withstand environmental conditions and provide consistent readings over time. |

| Tip 4: Regular Maintenance | Conducting regular maintenance helps prevent wear and tear on thermistors, ensuring they remain accurate and reliable. Regular checks and cleaning can identify potential issues early, reducing the risk of failure. |

| Tip 5: Shielding from Interference | Protecting thermistors from electromagnetic interference (EMI) and other environmental factors is critical for maintaining accuracy. Use shielded cables and proper grounding techniques to minimize EMI, and ensure thermistors are housed in protective enclosures if exposed to harsh conditions. |

Detailed Descriptions

Tip 1: Proper Calibration

- Importance: Calibration is essential to correct any drift in the thermistor’s readings over time. It ensures that the thermistor’s resistance values accurately correspond to the actual temperatures, maintaining measurement precision.

- Practice: Perform calibration at regular intervals, as recommended by the manufacturer or based on the operating environment.

Tip 2: Optimal Placement

- Best Practices:

- Place thermistors in a location representative of the medium being measured.

- Avoid areas with direct exposure to heat sources or rapid airflow that can cause temperature fluctuations.

- Ensure good thermal contact with the surface or fluid being measured for accurate readings.

Tip 3: Using High-Quality Materials

- Importance: High-quality materials offer better resistance to environmental factors, ensuring longer lifespan and consistent performance.

- Practice:

- Choose thermistors made from materials with high stability and low susceptibility to aging and environmental stress.

- Ensure that the materials are suitable for the specific application and operating conditions.

Tip 4: Regular Maintenance

- Importance: Regular maintenance keeps thermistors functioning correctly and identifies issues before they lead to inaccuracies or failures.

- Practice:

- Inspect thermistors regularly for signs of wear, corrosion, or damage.

- Clean the thermistors and their surroundings to remove any contaminants that might affect readings.

- Replace any thermistors showing signs of significant wear or degradation.

Tip 5: Shielding from Interference

- Importance: EMI and other environmental factors can distort thermistor readings, leading to inaccuracies.

- Practice:

- Use shielded cables to reduce EMI.

- Implement proper grounding techniques.

- House thermistors in protective enclosures to shield them from physical and environmental damage, especially in harsh or noisy environments.

FAQ on “Thermistors”

Q: What is a thermistor?

A: A thermistor is a temperature sensor whose resistance changes with temperature.

Q: How does a thermistor differ from a thermocouple?

A: Thermistors are more sensitive to small temperature changes, while thermocouples cover a broader temperature range.

Q: Why is calibration important for thermistors?

A: Calibration ensures accurate and reliable temperature measurements by compensating for drift.

Q: What are common applications of thermistors?

A: Thermistors are used in medical devices, automotive systems, consumer electronics, and industrial processes.

Conclusion

Thermistors are invaluable components for precise temperature measurement and control across various applications. By following the best practices for calibration, optimal placement, material selection, regular maintenance, and shielding from interference, you can ensure their ultimate precision and reliability. Whether used in medical devices, automotive systems, consumer electronics, or industrial processes, these tips will help you achieve accurate and consistent temperature readings, enhancing performance and safety in your operations. Embrace these power tips to maximize the effectiveness of thermistors in your specific applications.