Thermocouples

Thermocouples are vital temperature sensors used across various industries to ensure precise and reliable temperature measurements. Their ability to withstand extreme conditions while providing accurate readings makes them indispensable, particularly in industrial applications like ship engine rooms and other onboard machinery. Ensuring high precision and durability is crucial to avoid inefficiencies and safety hazards in such critical environments.

In this article, we present seven proven tips to enhance the performance of thermocouples. These actionable insights will help you optimize accuracy, maintain durability, and ensure consistent temperature monitoring in your processes. By implementing these strategies, you can improve operational efficiency, reduce errors, and enhance safety standards in your industrial environment. Whether you’re dealing with power generation, manufacturing, or any other application requiring precise temperature control, these tips will guide you toward maximizing the reliability and lifespan of your thermocouples, ensuring your ship’s engine room and other onboard machines operate at their best.

Understanding Thermocouples

| Section | Details |

|---|---|

| What are Thermocouples? | Thermocouples are temperature sensors that measure temperature through the voltage generated at the junction of two different metals (Seebeck effect). |

| Types of Thermocouples | Type K (Nickel-Chromium/Nickel-Alumel): General-purpose, -200°C to 1260°C, good accuracy and wide range. |

| Type J (Iron/Constantan): Older equipment, -40°C to 750°C, low cost, limited range. | |

| Type T (Copper/Constantan): Cryogenic/low-temp, -200°C to 350°C, excellent accuracy/stability, corrosion resistant. | |

| Type E (Nickel-Chromium/Constantan): High-accuracy, -200°C to 900°C, high output (mV). | |

| Type N (Nicrosil/Nisil): High-temp, -200°C to 1300°C, excellent stability, high-temp oxidation resistant. | |

| Importance of Accuracy and Durability | Operational Efficiency: Ensures optimal process parameters, reduces waste. |

| Safety: Prevents dangerous conditions (e.g., overheating), protects equipment/personnel. | |

| Product Quality: Maintains quality, critical in manufacturing/pharmaceuticals. | |

| Cost Savings: Durable/accurate thermocouples reduce replacements/repairs, saving costs. | |

| Compliance: Ensures adherence to industry regulations regarding temperature control. |

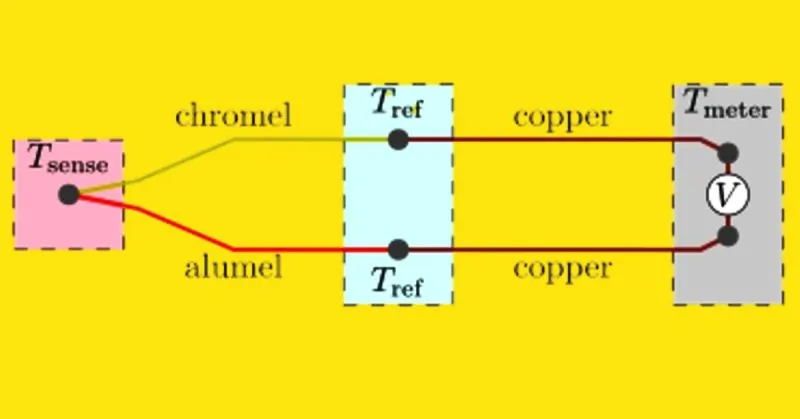

Circuit Diagram and Working of a Thermocouple

Components:

- Tsense (Sensing Junction):

- The point where the two dissimilar metals (Chromel and Alumel) are joined together. This junction is placed in the environment where temperature measurement is required.

- Chromel:

- An alloy consisting primarily of nickel and chromium. It serves as one of the thermoelements in the thermocouple and is connected to Tsense.

- Alumel:

- An alloy composed of nickel, manganese, aluminum, and silicon. It is the second thermoelement in the thermocouple and is also connected to Tsense.

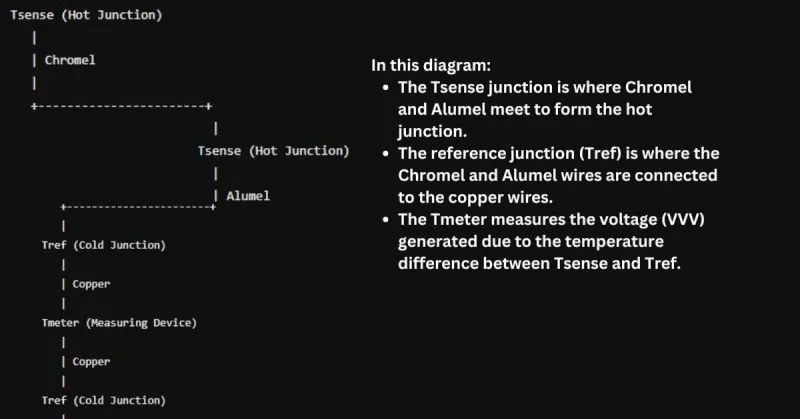

- Tref (Reference Junction):

- The junction where the Chromel and Alumel wires are connected to the copper wires. This junction is usually maintained at a known reference temperature (often 0°C or ambient temperature).

- Copper:

- Conductive wires that connect the reference junction (Tref) to the measuring device (Tmeter). Copper is chosen for its high conductivity and low thermoelectric effect.

- Tmeter (Measuring Device):

- The device used to measure the voltage generated by the thermocouple. It interprets the voltage difference and displays the corresponding temperature.

- V (Voltage):

- The voltage generated due to the temperature difference between the Tsense and Tref. This voltage is measured by the Tmeter.

Working Principle:

- Seebeck Effect:

- When the Tsense is exposed to the temperature (Tsense), a thermoelectric voltage (V) is generated between the two dissimilar metals (Chromel and Alumel). This occurs due to the Seebeck effect, where a temperature difference creates an electromotive force (EMF).

- Reference Junction (Tref):

- The reference junction is kept at a known temperature (Tref). This known temperature is crucial for accurate temperature measurement because the voltage generated is proportional to the temperature difference between the Tsense and Tref.

- Voltage Measurement:

- The voltage (V) generated due to the temperature difference is carried by the copper wires to the Tmeter. Copper is used because it introduces minimal additional EMF.

- The Tmeter measures the voltage and, using the known characteristics of the Chromel-Alumel thermocouple (calibration data), converts this voltage into a temperature reading.

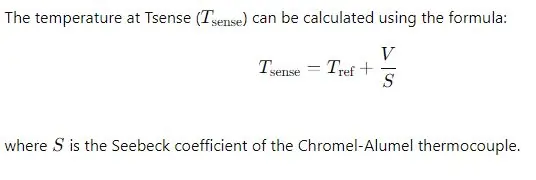

4. Temperature Calculation:

Diagram Explanation:

The thermocouple circuit can be illustrated as follows:

Choosing the Right Type of Thermocouple

Assessing Application Needs

When selecting a thermocouple, it is essential to assess the specific needs of the application to ensure optimal performance and longevity. Consider the following factors:

- Temperature Range:

- Determine the operating temperature range of the application. Different thermocouple types have varying temperature limits, and choosing one that matches your requirements is crucial for accuracy and durability.

- Environment:

- Assess the environmental conditions where the thermocouple will be used. Consider factors such as exposure to corrosive substances, moisture, vibration, and mechanical stress. Some thermocouples are more resistant to harsh conditions than others.

- Accuracy Requirements:

- Identify the level of precision needed for the application. Some thermocouple types offer higher accuracy and stability, which is critical for applications requiring precise temperature control.

- Response Time:

- Consider the response time required for your application. Fast response times are crucial in dynamic environments where temperature changes rapidly.

- Installation Constraints:

- Evaluate the physical space and mounting options available for the thermocouple. Some types are more flexible and easier to install in confined spaces.

Matching Thermocouple Type to Application

Once you have assessed the application needs, you can match the appropriate thermocouple type to ensure optimal performance. Here is detailed guidance on selecting the right thermocouple for specific industrial applications:

- Type K (Nickel-Chromium/Nickel-Alumel):

- Applications: General-purpose applications, such as power generation, chemical processes, and food industry.

- Temperature Range: -200°C to 1260°C.

- Advantages: Good accuracy, wide temperature range, and durability in oxidizing environments.

- Type J (Iron/Constantan):

- Applications: Older equipment, HVAC systems, and low-temperature industrial processes.

- Temperature Range: -40°C to 750°C.

- Advantages: Low cost and good performance in lower temperature ranges, but less durable at higher temperatures.

- Type T (Copper/Constantan):

- Applications: Cryogenic and low-temperature measurements, laboratory environments, and pharmaceuticals.

- Temperature Range: -200°C to 350°C.

- Advantages: Excellent accuracy and stability at low temperatures, resistant to corrosion in moist environments.

- Type E (Nickel-Chromium/Constantan):

- Applications: High-accuracy applications, such as medical devices and precision instrumentation.

- Temperature Range: -200°C to 900°C.

- Advantages: High output (mV), excellent for low-temperature measurements, and good accuracy.

- Type N (Nicrosil/Nisil):

- Applications: High-temperature measurements, such as in aerospace, metallurgy, and industrial furnaces.

- Temperature Range: -200°C to 1300°C.

- Advantages: Excellent stability and resistance to high-temperature oxidation, making it ideal for prolonged high-temperature use.

Proper Installation Techniques

| Section | Details |

|---|---|

| Correct Placement | Optimal Measurement Point: Place the thermocouple at the most accurate measurement point. Avoid areas with temperature gradients or external heat influences. |

| Minimizing Thermal Interference: Ensure the thermocouple is not influenced by external heat sources. Use shielding or insulation to minimize interference. | |

| Depth of Insertion: Insert the thermocouple to an appropriate depth to avoid surface temperature effects and unnecessary wear. | |

| Securing Connections | Proper Termination: Use the correct connectors and terminals. Ensure connections are clean and free from oxidation or corrosion. |

| Mechanical Stability: Secure thermocouple wires to prevent movement or vibration. Use clamps, cable ties, or other methods to keep wires in place. | |

| Electrical Insulation: Insulate connections to prevent electrical interference and short circuits. | |

| Avoiding Common Installation Mistakes | Incorrect Placement: Avoid placing thermocouples in areas with temperature gradients or external heat sources. Position in a stable location with proper insertion depth. |

| Poor Connection Quality: Use appropriate connectors and ensure connections are clean, secure, and insulated. | |

| Improper Insulation: Properly insulate thermocouple wires to shield from electrical noise and prevent short circuits. | |

| Mechanical Stress: Secure wires to minimize movement and mechanical stress. Use clamps or ties for stability. | |

| Ignoring Calibration Needs: Regularly calibrate thermocouples to maintain accuracy and reliability. |

Key Formulas for Thermocouple Applications

Understanding the mathematical principles behind thermocouples can greatly enhance their effective use in industrial and marine settings. Below are some essential formulas:

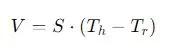

Seebeck Effect Equation

- Explanation: This formula calculates the voltage generated by a thermocouple due to the temperature difference between the hot and reference junctions.

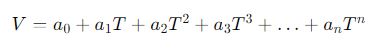

Thermocouple Voltage Output

- Explanation: This polynomial approximation helps find the output voltage for different types of thermocouples based on temperature differences.

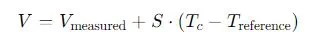

Cold Junction Compensation

- Explanation: This formula adjusts the measured voltage to account for the cold junction temperature, ensuring accurate readings.

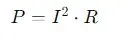

Power Dissipation in Thermocouple Wires

- Explanation: This equation calculates the power dissipation in thermocouple wires due to resistance and current.

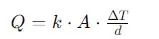

Heat Transfer Equation

- Explanation: Fourier’s law is used to determine the heat conducted through the thermocouple wire.

Using High-Quality Materials

Selecting Durable Materials

Using high-quality materials in thermocouples is essential for ensuring their longevity and consistent performance. Here’s why:

- Enhanced Longevity: High-quality materials resist wear and tear, reducing the need for frequent replacements and maintenance. This increases the lifespan of the thermocouples, ensuring reliable temperature measurements over extended periods.

- Consistent Performance: Materials that can withstand extreme temperatures and harsh conditions maintain their integrity and functionality, providing consistent and accurate readings crucial for industrial processes.

- Reduced Downtime: Durable materials minimize the risk of thermocouple failure, leading to less downtime and increased productivity. This is especially important in industries where continuous operation is vital.

Material Compatibility

Ensuring that the materials used in thermocouples are compatible with the environment is crucial for their effective operation. Consider the following factors:

- Corrosion Resistance: In environments where the thermocouples are exposed to corrosive substances, selecting materials with high corrosion resistance is essential. For example, thermocouples used in chemical processing should be made from materials like stainless steel or Inconel.

- Temperature Tolerance: Different applications require thermocouples to operate within specific temperature ranges. Materials must be chosen based on their ability to withstand these temperatures without degrading. For instance, platinum-based thermocouples are ideal for high-temperature applications.

- Mechanical Strength: The materials should be able to endure mechanical stresses such as vibrations, impacts, and pressure. This is particularly important in applications like aerospace or heavy machinery where mechanical integrity is critical.

Case Studies

Here are some examples of industries that have successfully used high-quality materials to enhance the performance and durability of their thermocouples:

- Aerospace Industry:

- Application: Monitoring engine temperatures in aircraft.

- Materials Used: Platinum-Rhodium and Nickel-based alloys.

- Outcome: These materials provided reliable performance under extreme temperature conditions, ensuring safety and efficiency in flight operations.

- Chemical Processing:

- Application: Temperature measurement in reactors and pipelines.

- Materials Used: Stainless steel and Inconel.

- Outcome: The use of corrosion-resistant materials extended the lifespan of thermocouples, reducing maintenance costs and improving process reliability.

- Power Generation:

- Application: Monitoring temperatures in boilers and turbines.

- Materials Used: Nickel-based alloys and Platinum.

- Outcome: High-quality materials ensured consistent and accurate temperature measurements, contributing to optimal operation and efficiency of power plants.

- Food and Beverage Industry:

- Application: Temperature control in cooking and pasteurization processes.

- Materials Used: Food-grade stainless steel.

- Outcome: Durable and hygienic materials maintained accuracy and compliance with safety standards, ensuring product quality.

Protecting from Environmental Factors

Shielding from Interference

Electromagnetic interference (EMI) can significantly affect the accuracy of thermocouple readings. Here are some techniques to protect thermocouples from EMI:

- Use Shielded Cables: Shielded cables are designed to block external electromagnetic fields. Ensure that the shield is grounded properly to maximize its effectiveness.

- Twisted Pair Wiring: Twisting the thermocouple wires together can help cancel out electromagnetic noise. This method is particularly effective for minimizing low-frequency interference.

- Separation from Power Lines: Keep thermocouple wires away from power lines and other sources of electromagnetic fields. Maintaining physical separation reduces the likelihood of interference.

Temperature Extremes and Mechanical Stress

Thermocouples often operate in harsh environments, where they are exposed to extreme temperatures and mechanical stresses. Here are strategies to safeguard against these conditions:

- Use High-Temperature Materials: Select thermocouples made from materials that can withstand the specific temperature range of your application. For high-temperature environments, materials like platinum and nickel-based alloys are ideal.

- Protective Sheaths: Utilize protective sheaths made from materials like stainless steel or ceramic. These sheaths provide an extra layer of protection against physical damage and extreme temperatures.

- Mechanical Supports: Implement mechanical supports to prevent vibrations and impacts. Secure the thermocouple in place using clamps, brackets, or other mounting solutions to minimize mechanical stress.

Insulation and Housing Solutions

Proper insulation and housing are crucial for enhancing the durability and performance of thermocouples. Consider the following options:

- Thermal Insulation: Use thermal insulation materials to protect the thermocouple from external temperature fluctuations. Insulation helps maintain a stable environment for accurate readings.

- Waterproof Housing: In environments exposed to moisture, waterproof housing prevents water ingress and corrosion. Use hermetically sealed enclosures to protect the thermocouple.

- Chemical-Resistant Coatings: Apply chemical-resistant coatings to protect the thermocouple from corrosive substances. This is particularly important in chemical processing and similar industries.

- Flexible Housings: For applications requiring movement or flexibility, consider using flexible housings made from materials like silicone or Teflon. These housings protect the thermocouple while allowing necessary movement.

Integration with Modern Systems

| Section | Details |

|---|---|

| Benefits of Modern Data Acquisition Systems | Improved Accuracy: Modern data acquisition systems enhance the accuracy of temperature measurements by reducing human error and providing high-resolution data logging. |

| Enhanced Monitoring: Integrating thermocouples with IoT and modern systems allows for continuous monitoring and remote access to temperature data. | |

| Data Analytics: Advanced systems provide powerful data analytics tools, enabling better decision-making and process optimization based on accurate temperature readings. | |

| Implementation Strategies | Assess Current Systems: Evaluate existing data systems and determine the requirements for integration with thermocouples. |

| Select Compatible Hardware and Software: Choose data acquisition hardware and software that are compatible with your thermocouples and can handle the specific data needs. | |

| Install and Configure Sensors: Properly install and configure the thermocouples to ensure accurate data transmission to the acquisition system. | |

| Test and Validate: Perform thorough testing and validation to ensure that the integrated system is functioning correctly and providing accurate data. | |

| Real-Time Monitoring | Immediate Data Access: Real-time monitoring provides instant access to temperature data, allowing for timely responses to any irregularities or critical changes. |

| Predictive Maintenance: Continuous monitoring enables predictive maintenance by identifying trends and potential issues before they result in equipment failure or downtime. | |

| Increased Operational Efficiency: Real-time data allows for dynamic adjustments to processes, leading to improved operational efficiency and reduced wastage. |

Regular Maintenance and Inspection

| Section | Details |

|---|---|

| Routine Checks | Detect Wear and Tear: Regular inspections identify wear and tear early, preventing unexpected failures. |

| Ensure Accuracy: Routine checks allow for calibration, ensuring precise temperature readings and maintaining quality and safety. | |

| Minimize Downtime: Early detection of potential issues helps schedule maintenance during planned downtimes, reducing unexpected interruptions. | |

| Maintenance Best Practices | Regular Calibration: Schedule calibrations at least annually to maintain accuracy. Frequency depends on application and conditions. |

| Proper Cleaning: Clean thermocouples regularly with appropriate methods to remove contaminants without damaging the sensors. | |

| Secure Connections: Ensure all connections are tight and secure to prevent signal loss and inaccurate readings. | |

| Protective Sheaths: Use protective sheaths to guard against physical damage and corrosive environments. Inspect regularly for wear or damage. | |

| Storage: Store thermocouples in a dry, clean environment when not in use to prevent damage and contamination. | |

| Troubleshooting Common Issues | Drift in Readings: Regularly calibrate and clean thermocouples to address drift caused by aging, contamination, or calibration issues. Replace if significant drift persists. |

| Intermittent Signals: Check and secure all connections, clean corroded contacts, and replace damaged connectors to fix intermittent signals. | |

| Physical Damage: Inspect thermocouples for physical damage, use protective sheaths, and secure to minimize mechanical stress. | |

| Environmental Interference: Use shielded cables and proper insulation to protect against EMI, and select materials suited for the specific environmental conditions. |

Key Formulas for Thermocouple Applications

Understanding the mathematical principles behind thermocouples can greatly enhance their effective use in industrial and marine settings. Below are some essential formulas

FAQ on Thermocouples

What is a thermocouple?

A sensor that measures temperature via voltage from two metals.

How do I choose the right thermocouple type?

Match it to your application’s temperature and environment.

Why is regular calibration important?

To maintain measurement accuracy.

How can I protect thermocouples from interference?

Use shielded cables and protective sheaths.

Conclusion

Ensuring the optimal performance of thermocouples in industrial applications requires attention to detail in selection, installation, maintenance, and integration with modern systems. By choosing high-quality materials, implementing proper installation techniques, and conducting regular maintenance and inspections, you can enhance the accuracy, reliability, and longevity of these vital temperature sensors. Additionally, protecting thermocouples from environmental factors and leveraging modern data acquisition systems for real-time monitoring will further boost operational efficiency and safety. Adopting these best practices will not only prevent costly downtimes and ensure compliance with industry standards but also contribute to the overall success and stability of your industrial processes.