Toroidal Transformers

In today’s fast-paced technological landscape, efficient power management is more crucial than ever. As we strive for more compact, high-performance devices, the role of transformers in delivering reliable and efficient power cannot be overstated. Enter toroidal transformers—an innovative solution redefining the standards of power efficiency and performance. With their distinctive doughnut-shaped design, toroidal transformers are revolutionizing various industries, from cutting-edge audio equipment to advanced medical devices.

Unlike traditional transformers, toroidal transformers offer several unparalleled advantages that make them indispensable in modern applications on Switchgear. This blog post will explore the five ultimate benefits of toroidal transformers, demonstrating why they are the preferred choice for tech innovators. We’ll delve into their superior efficiency, compact and lightweight design, reduced electromagnetic interference (EMI), quiet operation, and versatile mounting options. By understanding these key benefits, you’ll gain insight into why toroidal transformers are shaping the future of power management in today’s tech-driven world.

Superior Efficiency

Explanation

Toroidal transformers are celebrated for their exceptional efficiency, a feature that distinguishes them from traditional laminated transformers. This efficiency is primarily due to their unique toroidal (doughnut-shaped) core, which ensures that nearly all magnetic flux is confined within the core material, minimizing energy losses. The continuous winding around the core allows for a uniform distribution of the magnetic field, reducing the amount of energy dissipated as heat.

Technical Insights

The high efficiency of toroidal transformers is attributed to several key factors:

- Core Materials: High-quality core materials such as silicon steel or ferrite are used, which have excellent magnetic permeability and low hysteresis losses. These materials ensure that the magnetic flux travels with minimal resistance and energy loss.

- Design: The toroidal shape eliminates air gaps in the magnetic path, which are common in traditional transformers. This design reduces core losses and increases the transformer’s overall efficiency.

- Construction: The winding process of toroidal transformers is more precise, with wire wound tightly around the core, minimizing resistance and optimizing the magnetic coupling between the primary and secondary windings. This results in reduced stray losses and improved energy transfer.

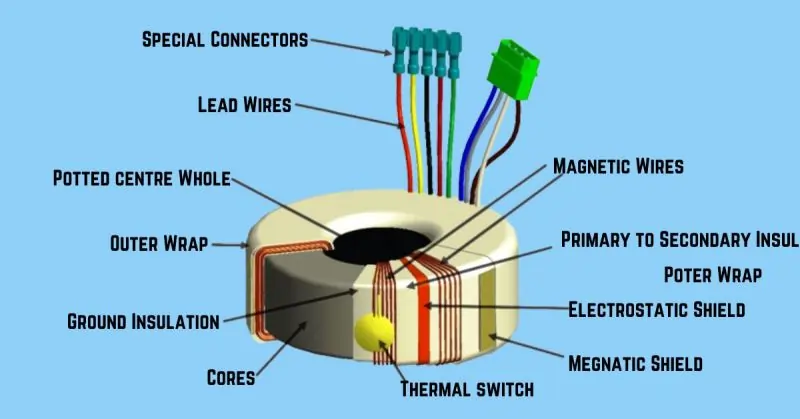

Toroidal Transformers Design

Toroidal transformers are designed with several key components that contribute to their functionality, efficiency, and reliability. Here’s an explanation of the functions of each critical component in their design:

Magnetic Wires (Copper)

- Function: Copper wires are used for the windings around the toroidal core.

- Impact: Copper’s excellent conductivity allows for efficient transmission of electrical energy, reducing resistive losses and improving overall transformer efficiency.

Primary to Secondary Insulation

- Function: This insulation separates the primary and secondary windings to prevent electrical shorts and ensure safety.

- Impact: Proper insulation is crucial for maintaining the integrity of the transformer and ensuring that the primary and secondary circuits remain electrically isolated, which is essential for safe and reliable operation.

Electrostatic Shield

- Function: An electrostatic shield is placed between the primary and secondary windings.

- Impact: This shield helps to reduce capacitive coupling and minimize noise and interference, improving the transformer’s performance in sensitive electronic applications.

Magnetic Shield

- Function: A magnetic shield is used to contain the magnetic fields within the transformer.

- Impact: This shield prevents external magnetic fields from interfering with the transformer and reduces electromagnetic emissions from the transformer, ensuring minimal EMI.

Thermal Switch

- Function: A thermal switch monitors the temperature of the transformer.

- Impact: This switch provides protection by disconnecting the transformer from the power supply if it overheats, preventing damage and enhancing safety.

Cores

- Function: The core is the doughnut-shaped ferromagnetic material that the windings are wrapped around.

- Impact: The core provides a path for the magnetic flux, which is crucial for the transformer’s operation. The toroidal shape ensures high efficiency by minimizing core losses and leakage inductance.

Ground Insulation

- Function: Ground insulation ensures that the core and other parts are properly insulated from the ground.

- Impact: This prevents electrical faults and improves the safety and reliability of the transformer.

Polyester Wrap

- Function: A polyester wrap is used to cover the windings and provide additional insulation and protection.

- Impact: This wrap protects the windings from environmental factors like moisture and dust, enhancing the durability and lifespan of the transformer.

Potted Centre Hole

- Function: The center hole of the toroidal transformer is often potted with a resin or other material.

- Impact: Potting provides mechanical stability and additional insulation, protecting the core and windings from mechanical stress and environmental conditions.

Lead Wires

- Function: Lead wires are used to connect the windings of the transformer to external circuits.

- Impact: High-quality lead wires ensure reliable electrical connections and efficient power transmission to and from the transformer.

Special Connectors

- Function: Special connectors may be used for connecting the transformer to various devices.

- Impact: These connectors facilitate easy and secure connections, ensuring reliable operation and easy integration into different applications.

Outer Wrap

- Function: The outer wrap encases the entire transformer assembly.

- Impact: It provides additional protection and insulation, enhancing the overall durability and safety of the transformer.

Real-World Applications

The superior efficiency of toroidal transformers has a significant impact on performance in various applications:

- Audio Equipment: In high-fidelity audio systems, efficient power delivery is crucial for maintaining sound quality. Toroidal transformers provide clean, stable power, reducing noise and distortion, which enhances the overall listening experience.

- Power Supplies: In power supply units, higher efficiency means less energy is wasted as heat. This not only improves the power supply’s performance but also extends its lifespan and reliability by reducing thermal stress on components.

Brands

Several leading brands are known for producing high-efficiency toroidal transformers:

- Talema: Renowned for their high-quality toroidal transformers, Talema offers products that excel in efficiency and reliability.

- Noratel: Noratel specializes in innovative transformer solutions, including highly efficient toroidal transformers for various industrial and consumer applications.

- Antek: Antek provides a range of toroidal transformers known for their superior performance and efficiency, catering to audio equipment, power supplies, and more.

Compact and Lightweight Design

| Compact and Lightweight Design | |

|---|---|

| Description | Toroidal transformers have a doughnut-shaped core that makes them smaller and lighter than traditional laminated transformers. The windings encircle the core evenly, creating a compact and efficient design. |

| Benefits | |

| Medical Devices | Reduced size allows for more compact and portable medical equipment designs. |

| Consumer Electronics | Ideal for devices requiring efficient power conversion in limited space, like audio amplifiers and home theater systems. |

| Industrial Equipment | Easier installation and lower transportation costs due to reduced weight and size. |

| Comparative Analysis | |

| Size and Weight | Typically 50% smaller and lighter than traditional laminated transformers. |

| Performance | Reduced leakage inductance and stray magnetic fields improve performance. |

| Installation | Easier to install, especially in space-limited or weight-critical applications. |

| Brands | |

| Triad Magnetics | Offers a range of compact, efficient toroidal transformers for consumer electronics and industrial applications. |

| Plitron | Known for high-quality toroidal transformers used in medical devices, audio equipment, and more. |

Reduced Electromagnetic Interference (EMI)

Technical Background

Toroidal transformers are designed to minimize electromagnetic interference (EMI) through their unique construction and shape. The toroidal core’s closed-loop design ensures that the magnetic flux is confined within the core material, reducing the leakage of magnetic fields into surrounding environments. This confinement is further enhanced by the uniform winding around the toroidal core, which balances the magnetic fields and cancels out external emissions. Additionally, the core material, typically made of high-quality silicon steel or ferrite, has low permeability, which helps in maintaining a stable and confined magnetic field.

Importance

Low EMI is crucial in sensitive electronic circuits where external electromagnetic fields can cause significant disruptions and degrade performance. In applications such as telecommunications, where signal integrity is paramount, minimizing EMI ensures clear and reliable communication. Similarly, in industrial control systems, low EMI is essential to prevent interference with control signals and ensure precise operation of machinery and processes. The reduction of EMI also contributes to compliance with regulatory standards for electromagnetic compatibility (EMC), which is a critical requirement in many industries.

Case Studies

- Telecommunications: In data centers and communication networks, toroidal transformers with low EMI are used to ensure that the high-speed data transmission is not disrupted by electromagnetic noise. This results in more reliable and faster communication services.

- Industrial Control Systems: In factories and automation systems, low-EMI toroidal transformers help maintain the integrity of control signals, leading to more accurate and efficient operation of industrial equipment. This is particularly important in environments with high electrical noise, where precise control is essential for safety and productivity.

Brands

- Schneider Electric: Schneider Electric is known for its high-performance toroidal transformers that offer superior EMI suppression, making them ideal for use in sensitive electronic applications.

- Hammond Manufacturing: Hammond Manufacturing specializes in low-EMI transformers that are widely used in telecommunications and industrial control systems, providing reliable performance in environments where electromagnetic interference is a concern.

Quiet Operation of Toroidal Transformers

| Aspect | Description |

|---|---|

| Mechanism | Toroidal transformers have a toroidal (doughnut-shaped) core that reduces noise and vibration. The symmetrical shape and uniform winding distribute the magnetic field evenly, minimizing hum and mechanical noise. |

| User Experience | The quiet operation of toroidal transformers is beneficial in both consumer and industrial applications. In consumer electronics, it enhances the user experience by reducing audible noise. In industrial settings, it contributes to a quieter work environment and minimizes interference with other sensitive equipment. |

| Industry Examples | Toroidal transformers are widely used in audio equipment, where low noise is critical for high-fidelity sound reproduction. They are also employed in other noise-sensitive environments, such as medical devices and precision measurement equipment, where silence is essential for accurate readings and patient comfort. |

| Brands | Brands known for producing quiet toroidal transformers include Toroid Corporation and Vanguard Electronics, both of which offer high-quality, low-noise transformers suitable for various applications. |

Versatile Mounting Options of Toroidal Transformers

| Aspect | Description |

|---|---|

| Design Flexibility | The symmetrical design of toroidal transformers allows for various mounting options. They can be mounted horizontally, vertically, or even suspended, providing great flexibility in placement. |

| Installation Benefits | The compact and lightweight nature of toroidal transformers makes them easy to install in different orientations. This versatility simplifies the design and layout of electronic systems, saving time and effort during installation. |

| Practical Examples | In limited space environments, such as compact electronic devices or densely packed industrial control panels, the versatile mounting options of toroidal transformers allow for optimal space utilization without compromising performance. |

| Brands | Brands like Avel Lindberg and Triad Magnetics are known for offering toroidal transformers with versatile mounting solutions, catering to a wide range of applications requiring flexible installation. |

Applications of Toroidal Transformers

| Applications | Description |

|---|---|

| Consumer Electronics | Toroidal transformers are used in high-fidelity audio systems, power supplies, and amplifiers. They provide clean, stable power, reducing noise and distortion to enhance sound quality and performance. |

| Medical Devices | These transformers are crucial in medical imaging equipment and diagnostic devices. Their compact size and low EMI properties ensure precise and reliable operation in sensitive medical environments. |

| Industrial Control Systems | In automation and control systems, toroidal transformers play a key role by providing efficient and reliable power. Their low EMI helps maintain the integrity of control signals for accurate machinery operation. |

| Telecommunications | Used in data centers and communication devices, toroidal transformers ensure stable power supply with minimal EMI, which is essential for maintaining clear and reliable communication signals. |

| Renewable Energy | Toroidal transformers are utilized in solar inverters and wind turbine systems. Their high efficiency and compact design help in converting renewable energy effectively and reliably. |

Troubleshooting Common Issues with Toroidal Transformers

| Issue | Description |

|---|---|

| Overheating | Causes: Overheating can be caused by excessive load, poor ventilation, or inadequate cooling. Solutions: Ensure proper ventilation and cooling, reduce the load, or use a transformer with a higher power rating. |

| Noise Issues | Identification: Noise or humming can be due to loose windings, magnetic core vibrations, or external magnetic fields. Mitigation: Tighten windings, secure the core, and shield the transformer from external magnetic fields. |

| Electrical Failures | Diagnosis: Common failures include short circuits, open circuits, or insulation breakdown. Repairs: Inspect and replace damaged windings, restore connections, and ensure proper insulation. |

| Installation Challenges | Tips: Ensure correct orientation and secure mounting, use appropriate mounting hardware, and follow manufacturer guidelines for installation. Consider using vibration-dampening mounts if noise is a concern. |

FAQ on “Toroidal Transformers”

Q: What makes toroidal transformers more efficient than traditional transformers?

A: Toroidal transformers have a closed-loop core design that minimizes magnetic losses and improves efficiency.

Q: How do toroidal transformers reduce electromagnetic interference (EMI)?

A: Their symmetrical design and uniform winding distribution confine the magnetic field within the core, reducing EMI.

Q: Why are toroidal transformers preferred in audio equipment?

A: They provide clean and stable power, reducing noise and distortion, which enhances sound quality.

Q: What are the benefits of the compact size of toroidal transformers?

A: Their compact size allows for space-saving designs in applications like medical devices and consumer electronics.

Conclusion

In the ever-evolving landscape of modern technology, toroidal transformers stand out as a critical component for efficient and reliable power management. Their superior efficiency, compact and lightweight design, reduced electromagnetic interference, quiet operation, and versatile mounting options make them indispensable in a wide range of applications. From high-fidelity audio systems and medical devices to industrial control systems and renewable energy solutions, toroidal transformers deliver performance and reliability that meet the demands of today’s advanced technologies.

Understanding the components and design intricacies of toroidal transformers allows for better implementation and troubleshooting, ensuring that these devices continue to provide optimal performance in their respective applications. Leading brands like Talema, Noratel, Antek, Triad Magnetics, Plitron, Schneider Electric, Hammond Manufacturing, Toroid Corporation, Vanguard Electronics, Avel Lindberg, and others offer high-quality toroidal transformers tailored to meet specific needs.

By leveraging the unique advantages of toroidal transformers, engineers and designers can create more efficient, quieter, and more reliable electronic systems. As technology continues to advance, the role of toroidal transformers will only become more vital, solidifying their place at the forefront of modern power solutions.