Turbocharger Bearings

Turbocharger bearings are crucial for the performance and longevity of a turbocharger, which boosts engine power by forcing more air into the combustion chamber. These small yet vital components ensure that the turbocharger spins smoothly at high speeds, reducing friction and heat, which is essential for maintaining efficiency and preventing damage. In modern engines, turbocharger bearings play a key role in enhancing performance and fuel efficiency. In this tutorial, you will learn about the different types of turbocharger bearings, their role in the system, and essential tips for maintaining them to ensure peak performance.

Understanding Turbochargers: A Brief Overview

Definition and Purpose: What is a Turbocharger?

A turbocharger is a device that increases the efficiency and power output of an engine by forcing extra air into the combustion chamber. By compressing more air into the engine, a turbocharger allows it to burn more fuel, which leads to a significant boost in power. This process is crucial for achieving higher performance without increasing engine size.

Turbocharger Components Explained

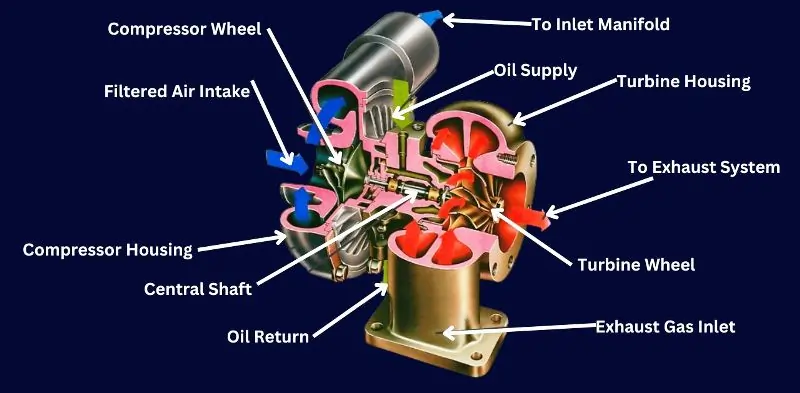

A turbocharger is a complex device made up of several critical components that work together to increase the engine’s power and efficiency. Here’s a breakdown of these components and their roles:

1. Compressor Wheel

The compressor wheel is a key part of the turbocharger’s compressor side. It spins at high speeds to draw in and compress ambient air, increasing its pressure before sending it into the engine’s combustion chamber. This compressed air allows the engine to burn more fuel, generating more power.

2. Filtered Air Intake

Before air reaches the compressor wheel, it passes through the filtered air intake. This component ensures that only clean, dust-free air enters the turbocharger, preventing damage to the compressor wheel and other internal components.

3. To Inlet Manifold

After the air is compressed by the compressor wheel, it is directed to the inlet manifold. The inlet manifold distributes the high-pressure air evenly to each cylinder in the engine, ensuring efficient combustion.

4. Oil Supply

The oil supply is essential for lubricating the turbocharger’s moving parts, particularly the central shaft and bearings. Proper lubrication minimizes friction, prevents overheating, and extends the lifespan of the turbocharger.

5. Turbine Housing

The turbine housing encases the turbine wheel and directs the exhaust gases from the engine towards it. The design of the turbine housing is crucial for maximizing the efficiency of the turbocharger, as it controls the flow of exhaust gases that drive the turbine wheel.

6. To Exhaust System

After passing through the turbine wheel, the exhaust gases exit the turbocharger through the exhaust system. The exhaust system channels these gases out of the vehicle, minimizing backpressure and enhancing engine efficiency.

7. Compressor Housing

The compressor housing surrounds the compressor wheel and directs the incoming air towards it. The shape of the compressor housing is designed to optimize airflow, ensuring that the air is efficiently compressed before being sent to the engine.

8. Turbine Wheel

The turbine wheel is located on the turbine side of the turbocharger and is driven by the exhaust gases from the engine. As the exhaust gases pass over the turbine wheel, they cause it to spin, which in turn drives the compressor wheel on the opposite side of the central shaft.

9. Central Shaft

The central shaft connects the turbine wheel and the compressor wheel. As the turbine wheel spins due to the force of exhaust gases, it drives the central shaft, which in turn rotates the compressor wheel to draw in and compress fresh air.

10. Oil Return

After the oil has lubricated the turbocharger’s moving parts, it flows back to the engine’s oil pan through the oil return line. This process ensures that the turbocharger remains well-lubricated and cool, preventing damage due to overheating.

11. Exhaust Gas Inlet

The exhaust gas inlet is where the hot gases from the engine’s exhaust system enter the turbocharger. These gases are directed toward the turbine wheel, where their energy is harnessed to drive the compressor wheel and boost engine performance.

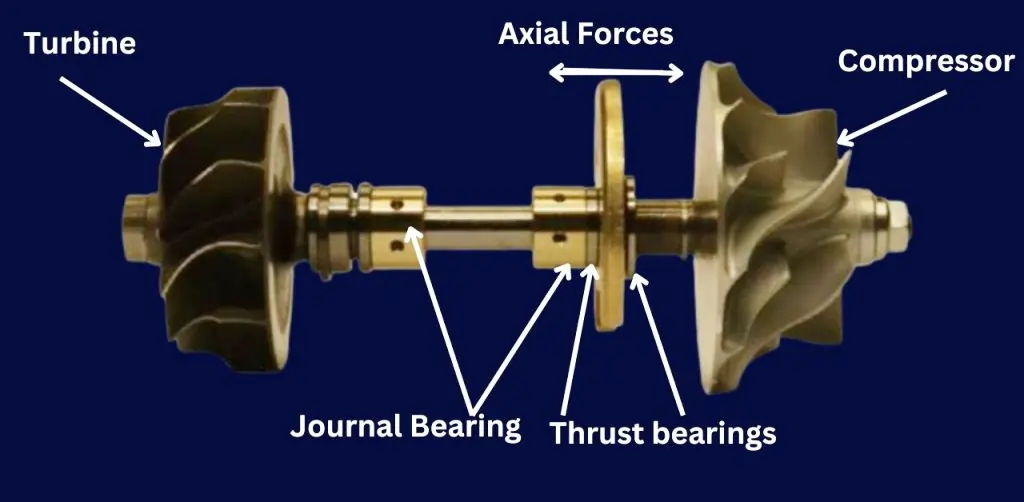

Focus on Bearings: Why Bearings are Integral to Turbocharger Functionality

Bearings are critical to the operation of a turbocharger. They support the turbocharger’s shaft, allowing it to spin at extremely high speeds—often exceeding 100,000 RPM. Without efficient bearings, the shaft would face excessive friction, leading to heat buildup, wear, and eventual failure. Bearings ensure smooth operation, reduce energy loss, and help maintain the durability and performance of the turbocharger over time. Understanding the role of bearings in this system is essential for anyone studying or working with turbochargers.

Types of Turbocharger Bearings

Turbocharger bearings are essential components that support the high-speed rotation of the turbocharger’s shaft, ensuring smooth and efficient operation. There are several types of bearings used in turbochargers, each with unique characteristics and applications. Here’s a detailed look at the main types:

1. Journal Bearings: How They Work and Where They’re Used

Journal bearings, also known as fluid bearings, are the most commonly used type of bearings in turbochargers. These bearings support the rotating shaft by creating a thin film of oil between the shaft and the bearing surface. This oil film reduces friction and wear, allowing the shaft to spin at high speeds—often exceeding 100,000 RPM—without direct metal-to-metal contact.

How They Work:

- Oil Film Formation: As the shaft spins, oil is pumped into the space between the shaft and the bearing, forming a lubricating film.

- Load Distribution: The oil film distributes the load evenly across the bearing surface, reducing localized stress and wear.

- Cooling Effect: The constant flow of oil helps dissipate heat generated by the high-speed rotation, preventing overheating.

Where They’re Used: Journal bearings are typically used in applications where high durability and cost-effectiveness are prioritized. They are common in large, heavy-duty turbochargers found in diesel engines for trucks, ships, and industrial equipment, where the ability to handle high loads over long periods is essential.

2. Ball Bearings: Advantages and Common Applications

Ball bearings use small spherical balls to reduce friction between the rotating shaft and the stationary housing. Unlike journal bearings, which rely on an oil film, ball bearings use rolling elements to minimize contact and friction, resulting in faster spool-up times and improved response.

Advantages:

- Quick Spool-Up: Ball bearings allow the turbocharger to reach operational speed more quickly, improving throttle response and overall engine performance.

- Lower Friction: The rolling elements significantly reduce friction, leading to higher efficiency and less heat generation.

- Durability at High Speeds: Ball bearings are better suited for high-speed operations, making them ideal for performance-focused turbochargers.

Common Applications: Ball bearings are commonly used in high-performance turbochargers, such as those found in sports cars and racing engines. Their ability to enhance responsiveness and efficiency makes them a popular choice for applications where quick acceleration and peak performance are critical.

3. Hybrid Bearings: Combining the Best of Both Worlds

Hybrid bearings combine elements of both journal and ball bearings to offer a balance of performance and durability. Typically, these bearings feature a journal bearing for supporting the main load and a ball bearing for reducing friction during high-speed operation.

Combining the Best Features:

- Load Handling: The journal bearing component handles the majority of the load, providing stability and longevity.

- Enhanced Performance: The ball bearing component reduces friction and improves spool-up times, enhancing turbocharger response.

Where They’re Used: Hybrid bearings are used in turbochargers that require a balance between performance and durability. They are often found in high-performance vehicles that need quick response times without compromising on longevity. This type of bearing is also used in some industrial and marine applications where both high performance and reliability are necessary.

4. Choosing the Right Bearing Type for Specific Turbocharger Applications

Selecting the right type of bearing for a turbocharger depends on the specific application and performance requirements. Here are some factors to consider:

- Engine Type: For heavy-duty engines, such as those in trucks or industrial machinery, journal bearings are often preferred due to their durability and load-handling capabilities.

- Performance Needs: In high-performance or racing engines, ball bearings are ideal for their quick response and low friction.

- Balance of Performance and Durability: Hybrid bearings are suitable for applications where a balance between quick spool-up times and long-term durability is required, such as in high-performance street cars or certain marine engines.

- Cost Considerations: Journal bearings are generally more cost-effective, making them a popular choice for larger turbochargers in industrial and marine settings, while ball and hybrid bearings, being more expensive, are often reserved for specialized high-performance applications.

Materials and Design of Turbocharger Bearings

Turbocharger bearings are designed to withstand extreme operating conditions, including high temperatures, high speeds, and heavy loads. The choice of materials and the design of these bearings are crucial factors that determine their performance, durability, and efficiency. Here’s a detailed look at the materials and design considerations for turbocharger bearings.

1. Common Materials: Steel, Ceramic, and Others

The materials used in turbocharger bearings must possess properties that allow them to endure harsh conditions while maintaining their integrity and performance. The most common materials include:

- Steel: Steel is the most widely used material for turbocharger bearings due to its strength, durability, and cost-effectiveness. Steel bearings are capable of handling high loads and are resistant to wear and deformation under extreme conditions. They are often alloyed with other elements to enhance their properties, such as adding chromium for increased corrosion resistance.

- Ceramic: Ceramic bearings are known for their exceptional hardness, low friction, and high-temperature resistance. These bearings are lighter than steel and can operate at higher speeds with less heat generation. However, ceramic bearings are more brittle and expensive, making them suitable for high-performance applications where weight reduction and efficiency are critical.

- Others: In some specialized applications, bearings may be made from other materials such as titanium or composite materials. These materials are chosen for their specific properties, such as high strength-to-weight ratio or enhanced resistance to corrosive environments.

2. Design Considerations: Heat Tolerance, Friction Reduction, and Durability

The design of turbocharger bearings is crucial to their performance and longevity. Key design considerations include:

- Heat Tolerance: Turbocharger bearings must withstand high temperatures generated by the turbocharger’s operation. Materials like steel and ceramic are selected for their ability to maintain structural integrity at elevated temperatures. Additionally, the design may incorporate features such as cooling channels or special coatings to enhance heat dissipation.

- Friction Reduction: Reducing friction is essential to ensure the smooth operation of the turbocharger at high speeds. Bearings are designed with precise tolerances and surface finishes to minimize contact between moving parts. In some cases, coatings such as diamond-like carbon (DLC) are applied to further reduce friction and wear.

- Durability: Durability is a critical factor in bearing design, especially for applications where the turbocharger operates under continuous or heavy-duty conditions. Bearings are designed to distribute loads evenly and resist deformation, ensuring long service life. The choice of material and manufacturing process plays a significant role in achieving the desired durability.

3. Manufacturing Techniques: Precision in Bearing Production

The manufacturing of turbocharger bearings requires a high level of precision to meet the demanding specifications needed for optimal performance. Key manufacturing techniques include:

- Precision Machining: Bearings are machined to exacting tolerances to ensure a perfect fit and smooth operation. This includes grinding, polishing, and honing processes to achieve the desired surface finish and dimensional accuracy.

- Heat Treatment: Heat treatment processes, such as annealing or tempering, are used to enhance the material properties of the bearings. This process improves hardness, wear resistance, and fatigue strength, making the bearings more durable and capable of withstanding the stresses of turbocharger operation.

- Coating Application: Advanced coatings are applied to bearings to reduce friction, increase wear resistance, and enhance heat tolerance. These coatings are applied using techniques such as physical vapor deposition (PVD) or chemical vapor deposition (CVD) to ensure a uniform and durable layer.

- Quality Control: Rigorous quality control measures are implemented throughout the manufacturing process to ensure that each bearing meets the required specifications. This includes dimensional inspections, material testing, and performance assessments to guarantee reliability and consistency.

Installation and Maintenance of Turbocharger Bearings

Proper installation and maintenance of turbocharger bearings are crucial for ensuring the longevity and optimal performance of a turbocharger. Neglecting these aspects can lead to premature wear, failure, and reduced engine efficiency. Below is a detailed guide on the best practices for installation, common mistakes to avoid, and essential maintenance tips.

1. Installation Best Practices: Ensuring Optimal Performance

Correct installation of turbocharger bearings is essential for the efficient operation of the turbocharger. Following best practices during installation can help prevent issues and extend the life of the bearings:

- Cleanliness is Key: Before installation, ensure that all components, including the bearings, turbocharger housing, and central shaft, are thoroughly cleaned. Even small particles of dirt or debris can cause significant damage once the turbocharger is operational.

- Use the Right Tools: Specialized tools should be used to install bearings to avoid damaging them. Using the correct tools helps in achieving precise alignment and prevents undue stress on the bearing surfaces.

- Proper Lubrication: Apply the appropriate type and amount of lubricant during installation. This ensures that the bearings are well-lubricated from the start, reducing friction and preventing metal-to-metal contact during initial operation.

- Alignment and Fit: Ensure that the bearings are correctly aligned and seated within their housings. Misalignment can cause uneven wear, increased friction, and eventual bearing failure.

- Torque Specifications: Adhere to the manufacturer’s recommended torque settings when fastening the bearings in place. Over-tightening or under-tightening can lead to improper bearing function and increased wear.

2. Common Mistakes to Avoid: Installation Errors and Their Consequences

Avoiding common mistakes during installation can save time, money, and prevent potential failures:

- Improper Cleaning: Failing to clean components thoroughly before installation can introduce contaminants that cause premature bearing wear or damage.

- Incorrect Bearing Orientation: Installing the bearings in the wrong orientation can lead to improper lubrication flow and increased friction, resulting in overheating and bearing failure.

- Over-Lubrication or Under-Lubrication: Both over-lubrication and under-lubrication can cause problems. Too much lubricant can cause excessive heat and pressure buildup, while too little can lead to increased friction and wear.

- Neglecting Torque Specifications: Not adhering to the specified torque settings can cause the bearings to be either too loose or too tight, leading to misalignment, excessive wear, or even catastrophic failure.

3. Maintenance Tips: Keeping Turbocharger Bearings in Top Condition

Regular maintenance is essential for prolonging the life of turbocharger bearings and ensuring the turbocharger operates efficiently:

- Regular Lubricant Checks: Monitor and maintain the correct oil levels and quality. Dirty or degraded oil can cause increased friction and wear on the bearings. Replace the oil according to the manufacturer’s recommendations.

- Inspect for Wear and Tear: Regularly inspect the turbocharger bearings for signs of wear, such as unusual noise, vibration, or leaks. Early detection of issues can prevent further damage and costly repairs.

- Keep the Air and Oil Filters Clean: Ensure that the air and oil filters are clean and functioning properly. Clogged filters can reduce lubrication flow and allow contaminants to reach the bearings, causing damage.

- Follow the Manufacturer’s Maintenance Schedule: Adhering to the recommended maintenance schedule provided by the manufacturer ensures that the bearings and other turbocharger components are serviced at the correct intervals, preventing unexpected failures.

- Check for Leaks: Regularly inspect for oil leaks around the turbocharger, as these can indicate worn seals or other issues that could affect bearing performance.

Diagnosing Bearing Issues in Turbochargers

Diagnosing issues with turbocharger bearings is essential for maintaining performance and avoiding costly failures. Here’s a detailed breakdown of the key areas to focus on:

Signs of Bearing Wear

- Noise: If you hear unusual sounds like whistling, whining, or grinding from the turbocharger, it could be a sign of bearing wear or damage.

- Vibration: Excessive vibration or wobbling during engine operation often points to potential issues with the bearings.

- Performance Drops: A noticeable decrease in engine performance, such as reduced power output or slower turbo spool-up times, can indicate that the bearings are worn out.

Troubleshooting Techniques

- Visual Inspection: Examine the turbocharger and bearings for any visible signs of wear, such as scoring, discoloration, or oil leaks.

- Check Oil Quality: Inspect the oil for metal particles or contamination, as this could signal bearing wear or an impending failure.

- Listen for Noises: Use a mechanic’s stethoscope or a similar tool to pinpoint the source of unusual noises and determine if they are coming from the bearings.

- Vibration Analysis: Conduct a vibration analysis to detect any abnormal vibrations, which may indicate bearing misalignment, wear, or damage.

- Measure Shaft Play: Check the central shaft for excessive play or movement, which can suggest that the bearings are worn and no longer providing proper support.

Repair vs. Replacement

- Repair: Minor bearing issues, such as slight wear or misalignment, can often be repaired. This may involve re-machining, rebalancing, or adjusting lubrication.

- Replacement: If the bearings show significant wear, pitting, or damage that cannot be repaired, or if there is a complete bearing failure, replacement is necessary.

- Cost and Downtime Consideration: Consider the cost and time required for repairs versus replacement. In high-performance or critical applications, replacing bearings may be more cost-effective in the long run.

- Long-Term Reliability: Think about the future reliability of repaired bearings versus new ones, especially in demanding environments where bearing performance is crucial.

Future Trends in Turbocharger Bearings

The future of turbocharger bearings is shaped by advancements in materials, the rise of electric turbochargers, and a growing focus on sustainability. As technology evolves, so too does the design and application of bearings, ensuring that they meet the demands of modern engines while addressing environmental concerns.

1. Innovations in Bearing Materials: What’s Next for Turbocharger Bearings?

The ongoing development of new materials is set to revolutionize turbocharger bearings, enhancing their performance and durability:

- Advanced Alloys: Future turbocharger bearings will likely incorporate advanced metal alloys that offer superior strength and heat resistance. These materials will allow bearings to operate efficiently under even more extreme conditions, extending their lifespan and reliability.

- Ceramic Bearings: The use of ceramic materials in bearings is expected to grow, thanks to their low friction, lightweight properties, and high resistance to wear and temperature. Innovations in ceramic composites may lead to bearings that perform even better under high-stress conditions, making them ideal for high-performance and racing applications.

- Self-Lubricating Materials: The development of self-lubricating materials could reduce the need for external lubrication, simplifying maintenance and reducing the risk of failure due to lubrication issues. These materials may also help improve efficiency by reducing friction and heat generation.

2. The Impact of Electric Turbochargers on Bearing Design

As the automotive industry shifts towards electrification, the introduction of electric turbochargers is changing the landscape of bearing design:

- Reduced Mechanical Stress: Electric turbochargers, which use electric motors to drive the compressor instead of exhaust gases, place different demands on bearings. These bearings may face less mechanical stress, allowing for designs that prioritize precision and efficiency over heavy load-bearing capacity.

- Optimized for Electric Drive: Bearings in electric turbochargers are likely to be optimized for the unique operating conditions of electric motors, such as higher rotational speeds and reduced vibration. This could lead to the development of specialized bearings that enhance the overall performance of electric turbocharging systems.

- Integration with Electronics: Future bearings may also integrate sensors and electronics to monitor performance in real-time, providing feedback on bearing condition and enabling predictive maintenance. This could be particularly valuable in electric turbochargers, where precise control and monitoring are essential.

3. Sustainability Considerations: Eco-friendly Bearings and Production Methods

As environmental concerns grow, the production and operation of turbocharger bearings are increasingly focusing on sustainability:

- Eco-friendly Materials: The development of eco-friendly materials, including recyclable metals and biodegradable lubricants, is becoming a priority. These materials aim to reduce the environmental impact of manufacturing and disposal while maintaining high performance and durability.

- Energy-efficient Production: Advances in manufacturing techniques are focusing on reducing energy consumption and waste during the production of bearings. Techniques such as additive manufacturing (3D printing) may become more prevalent, allowing for more precise and efficient production with less material waste.

- Lifecycle Management: The future of turbocharger bearings may include more comprehensive lifecycle management strategies, where bearings are designed for easier recycling or repurposing at the end of their life. This could involve designing bearings with modular components that can be replaced or upgraded rather than discarded.

Conclusion

In conclusion, turbocharger bearings are vital components that significantly influence the performance and longevity of a turbocharger. By understanding the different types of bearings, their materials, installation practices, and maintenance needs, you can ensure your turbocharger operates at its best. As technology advances, innovations in bearing design and materials, along with a focus on sustainability, will continue to enhance the efficiency and environmental impact of turbochargers. Whether you’re a student or a professional, staying informed about these developments will help you make the most of your turbocharger systems.

FAQs on Turbocharger Bearings

Q- What are the most common materials used in turbocharger bearings?

A- Steel and ceramic are the most common materials used in turbocharger bearings.

Q- How do you know when a turbocharger bearing needs replacement?

A- Unusual noises, vibration, oil leaks, or performance drops indicate the need for replacement.

Q- What is the difference between journal and ball bearings in turbochargers?

A- Journal bearings use oil films for durability, while ball bearings offer quicker spool-up and efficiency.

Q- Are there specific maintenance tips for extending the life of turbocharger bearings?

A- Regular oil changes, clean filters, and routine inspections help extend bearing life.