Turbocharger Blower and Turbine cleaning

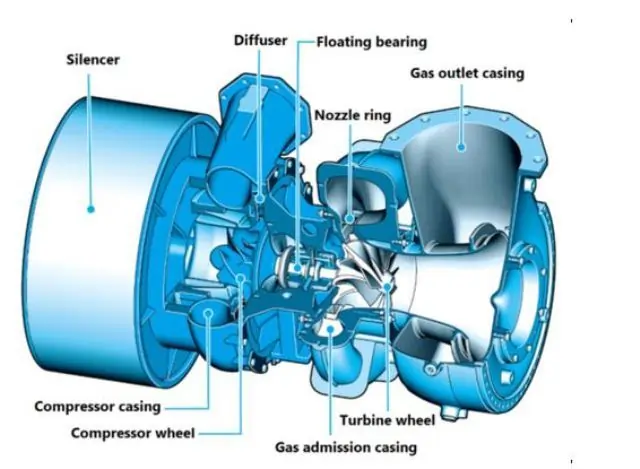

The turbocharger is like a special part of modern diesel engines that makes them work better. It makes the engine more powerful and uses less fuel by squishing the air before it goes into the engine. But as time goes by, the turbocharger can get dirty and clogged with stuff like dirt, trash, and oil. This makes it not work as well and could even hurt the engine.

To make sure the engine keeps working well and lasts a long time, it’s important to clean the turbocharger regularly. In this article, we’ll talk about why cleaning the turbocharger is so important, the steps to clean both its parts (the squisher and the spinner), and some good ways to do it. We’ll also talk about some common problems with turbochargers and how to fix them. Whether you really like diesel engines or you fix them for a job, this article will help you understand how to take care of your turbocharger and make it work its best.

It’s really important to keep the turbocharger’s squisher and spinner clean so that it works the right way. Cleaning them removes things like black stuff, dirt, and other trash that can make the turbocharger stop working well and not be as good at its job. That’s why it’s a must to clean both parts of the turbocharger – the squisher and the spinner – to keep it working really well.

एक टर्बो का टरबाइन पक्ष क्या है?

टर्बोचार्जर एक डीजल इंजन का एक महत्वपूर्ण घटक है जो इंजन के पावर आउटपुट को बढ़ाता है और इंजन के फ्यूल एफिशियंसी को बेहतर बनाता है। टर्बोचार्जर के दो प्रमुख भाग होते हैं – टरबाइन पक्ष और ब्लोअर पक्ष। टरबाइन पक्ष, जो टर्बाइन हाउसिंग में स्थान रखता है, द्वारा प्रवेश करने वाली धातु गैस को धार्मिक शक्ति में बदलता है। इस शक्ति का उपयोग ब्लोअर पक्ष द्वारा इंजन में उपयोग होने वाली वायु को नियंत्रित करने के लिए किया जाता है। अधिकतम फ़ायदा प्राप्त करने के लिए, टर्बोचार्जर के ब्लोअर और टरबाइन पक्षों को नियमित रूप से साफ करना आवश्यक होता है।

Turbocharger: Grid Washing vs. Water Washing

What is the Difference Between Grid Washing and Water Washing?

Turbochargers require regular cleaning to maintain efficiency and performance. Two common cleaning methods are Grid Washing and Water Washing, each with its benefits and drawbacks.

Grid Washing

- Process: Grid washing involves using a specially designed grid or mesh to clean the turbine blades by trapping and removing dirt, soot, and carbon deposits.

- Advantages:

- Effective at removing solid deposits that adhere strongly to the turbocharger blades.

- No risk of water contamination or corrosion in the turbocharger.

- Provides a deep, mechanical cleaning of hard-to-reach areas.

- Disadvantages:

- Requires the engine to be stopped and turbocharger dismantling, leading to downtime.

- Labor-intensive and time-consuming process.

- Grid washing is more suitable for major cleanups rather than regular maintenance.

Water Washing

- Process: Water washing involves injecting a fine spray of water or a water-detergent mixture into the air intake while the engine is running. This method helps to clean the turbine blades without stopping the engine.

- Advantages:

- Can be done while the engine is running, reducing downtime and improving operational efficiency.

- Effective for routine cleaning and removal of light soot and carbon deposits.

- Quick and less labor-intensive compared to grid washing.

- Disadvantages:

- Less effective for heavy carbon buildup or solid deposits.

- Potential risk of water ingress leading to corrosion or damage if not performed properly.

- Requires careful control of water quantity and temperature to avoid harming turbocharger components.

Conclusion

Grid Washing is ideal for heavy-duty cleaning during major maintenance, while Water Washing is more suited for routine, in-operation cleaning. Both methods are essential for maintaining turbocharger efficiency, and the choice depends on the severity of fouling and operational requirements.

Turbine Cleaning During Operation

The combustion of heavy fuel oil in diesel engines leaves dirty deposits on the turbocharger turbine blades and nozzle rings. The following products of combustion cause these deposits on the turbine components:

- Soot

- Molten ash

- Cinders

- Incompletely burned fuel

- Sodium vanadyl vanadate

It is, therefore, an advantage if fuels with a low content of ash, sulfur, sodium, and vanadium are used. The fuel, furthermore, must also be stored, prepared, and handled correctly.

The dirty deposits increase with time, so regular and proper cleaning is essential to remove what has accumulated.

The charging pressure can rise somewhat if dirty turbine components reduce the turbine cross-section. The dirty deposits cause a drop in turbine efficiency and a rise in engine temperatures after the cylinders.

This may mean that the engine output has to be reduced.

In addition, a dirty turbine results in rotor unbalance. Heavy deposits of dirt can lead to unacceptably high rotor imbalance.

Experience with turbocharger operation shows that despite regular cleaning while the installation is running, overhauls during which the turbine and nozzle ring are cleaned mechanically cannot be dispensed with. However, if cleaning is carried out correctly and the cleaning system is appropriately sized, the intervals between overhauls can be extended.

Turbine Side Cleaning Procedure

Dry Cleaning of Turbocharger – Turbine Side

Cleaning Procedure

1) Cleaning is performed at a high engine load of at least 75% at full load.

2) Before connecting the “blow gun”, open the shut-off valve (1) as shown above and make sure that the passage is secured.

3) Fill the container (2) with cleaning agent.

4) Connect the “blow gun” to the valve (1). Open the air valve (3). 5) Next, slowly open the valve (1), you will hear a whooshing sound as the granules are blown. (Injection time about 2 minutes)

Turbine Side Water Washing

Cleaning Procedure

1) Set the engine load to approximately 20% and wait 10 minutes for the engine to stabilize.

2) Open the drain cock of the turbocharger outlet and check the free passage. See Figure 1.

3) Turn the 3-way valve to position 2 OPEN. See Figure 2 for free passage. If OK, switch to rinsing position 3 “Wash”.

4) Connect the water supply to the water cleaning system.

5) Activate the operating valve (see Fig. 1). Then open the adjustment valve and adjust the water flow until the condensate flow is approximately 0.25 l/min.

6) Continue washing with water for 5-10 minutes. Or until the drain water is free of particles.

7) Loosen the operation valve and disconnect the water supply. Turn the three-way faucet to the “closed” position of 1 and check if the water has stopped.

8) Continue this exercise for at least 5 minutes. before raising the load to normal.

9) After washing with water, the engine should be run for at least 1 hour before stopping the engine.

Note: The control valve should open slowly. The operating valve must not lock in the open position. Do not exceed the irrigation time stated in point 6

Cleaning the compressor during operation

How dirty the compressor stage (compressor wheel and diffuser) becomes depends on how clean the drawn-in air is.

Deposits of dirt can build up in the flow ducts if the following substances are in the intake air:

- Oily or salty mist

- Solid combustion residues

- Various kinds of dust

Dirty deposits on the compressor stage negatively influence the compressor efficiency and charging pressure.

This results in higher exhaust temperatures and higher fuel consumption by the engine. Dirty deposits on the compressor can also increase the unbalancing of the rotor.

Regular compressor cleaning during operation can significantly prevent or slow fouling buildup. In no way does it replace the regular service work during which the turbocharger is completely dismantled, and the compressor is cleaned mechanically.

The interval between periodic cleanings varies greatly depending on the operating conditions. Generally, cleaning should be performed every 25 to 100 hours of operation.

Blower Side Cleaning Procedure

ब्लोअर साइड का वॉटर वॉशिंग क्या है?

ब्लोअर साइड वॉटर वॉशिंग एक विशेष प्रक्रिया है जो टर्बोचार्जर के ब्लोअर पक्ष को साफ करने के लिए किया जाता है। इस प्रक्रिया में, एक विशेष वॉशिंग सॉल्यूशन टर्बोचार्जर के ब्लोअर पक्ष में डाला जाता है और फिर इसे धीरे-धीरे चलाया जाता है। इस प्रक्रिया में, जल से पैक गंदगी, रसायन और तेल को साफ करने में मदद मिलती है। वॉटर वॉशिंग को नियमित रूप से किया जाना चाहिए ताकि टर्बोचार्जर के ब्लोअर पक्ष को साफ रखने से इंजन की ऊर्जा प्रदर्शन क्षमता और फ्यूल एफिशियेंसी में सुधार होता है।

Water Washing of Compressor Side

Before Cleaning:- The cleaning process can only be carried out when the engine is at operating temperature and as close to full load as possible.

Cleaning Procedure

1) Run the engine with as high a load as possible.

2) Before loosening the top lid, pull out the spindle of the relief valve (see Figure 1) to relieve excess pressure in the tank.

The spindle automatically returns by built-in spring

3) Fill the tank with 2 liters of fresh water (see tank scale). warning:

Do not use seawater or cooling water. 4) Attach the top cover to the container.

5) Blow air into the tank with a blow gun until an operating pressure of 3 bar is reached (see Fig. 2).

The safety valve opens at a pressure of 4 bar. Overpressure is discharged through a safety valve

Blog Conclusion

In conclusion, cleaning the turbocharger’s blower and turbine sides is a critical aspect of maintaining a diesel engine’s performance and longevity. By keeping these components free of dirt, debris, and oil buildup, you can ensure optimal engine power output, and fuel efficiency, and minimize the risk of costly engine damage. When cleaning the turbocharger, it’s important to follow the correct procedures and use the right tools to avoid causing any damage to the components.

By regularly cleaning your turbocharger and addressing any issues that arise promptly, you can keep your diesel engine running smoothly for years to come. Remember, a well-maintained turbocharger not only ensures optimal engine performance but also helps to reduce emissions and save you money on fuel costs.

FAQ on Turbocharger Blower and Turbine Sides cleaning

Why is cleaning the turbocharger’s blower and turbine sides important?

Cleaning the turbocharger is important to ensure optimal engine performance, fuel efficiency, and longevity. Dirt, debris, and oil buildup can clog the blower and turbine sides, reducing their effectiveness and potentially causing engine damage.

What tools are needed to clean the turbocharger?

Typically, you’ll need a set of basic hand tools, cleaning solutions, a soft-bristled brush, and a clean rag. Additionally, you may need some specialty tools such as an impact driver, torque wrench, or vacuum pump.

How often should I clean my turbocharger?

The frequency of cleaning will depend on several factors, including the engine’s usage and operating conditions. However, it’s generally recommended to clean the turbocharger’s blower and turbine sides at least once a year or more frequently if there are signs of buildup or reduced performance.

Can I clean the turbocharger myself, or do I need to take it to a professional mechanic?

With the right tools and knowledge, cleaning the turbocharger can be done yourself. However, if you’re not confident in your ability to do so or if there are any underlying issues with the turbocharger, it’s best to seek the help of a professional mechanic.

What are some signs that my turbocharger needs cleaning?

Reduced engine power output, decreased fuel efficiency, and unusual noises from the turbocharger are all signs that the blower and turbine sides may need cleaning. Additionally, if there is visible dirt, debris, or oil buildup on the turbocharger, it’s time for a cleaning.