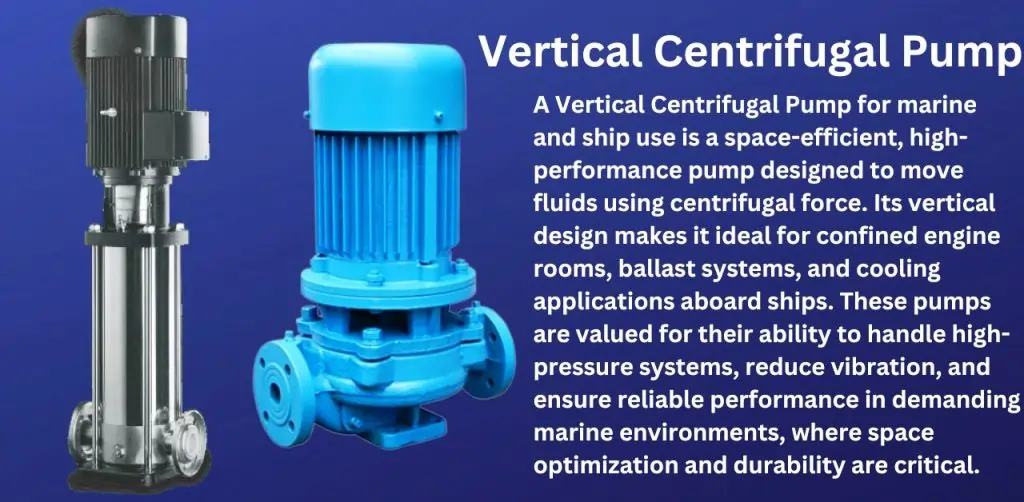

Vertical Centrifugal Pump

Centrifugal pumps are vital to numerous industries, ensuring the efficient movement of fluids in processes such as water treatment, chemical processing, oil and gas production, and marine systems. These pumps work by converting rotational kinetic energy into fluid flow, providing a reliable solution for transporting liquids. Among the various types, Vertical Centrifugal Pumps are particularly valuable for their space-saving design and high efficiency. Unlike their horizontal counterparts, vertical centrifugal pumps are built to fit in confined spaces, making them ideal for ships and marine environments where floor space is limited.

This vertical configuration not only optimizes installation but also helps reduce vibration, enhancing performance in high-pressure systems. These advantages make vertical centrifugal pumps indispensable in marine engineering, where space, efficiency, and durability are critical. In this post, we’ll explore their design, applications, and key benefits for marine and industrial use.

What is a Vertical Centrifugal Pump?

A Vertical Centrifugal Pump is a type of pump that operates using the principles of centrifugal force to move fluids. The basic working principle involves the rotation of an impeller, which creates a low-pressure zone at the center, drawing liquid into the pump. As the impeller spins, the liquid is pushed outward by centrifugal force, increasing its velocity and pressure as it moves through the pump and out of the discharge port.

Centrifugal pumps, in general, are widely used for their simplicity, efficiency, and ability to handle high flow rates with minimal maintenance. They are essential in industries like water treatment, oil and gas, and marine systems.

The key difference between vertical and horizontal centrifugal pumps lies in their configuration. Vertical centrifugal pumps are designed with the motor and impeller aligned vertically, saving floor space and reducing vibration. Horizontal centrifugal pumps, on the other hand, require more space for installation and are often used where vertical space is not a constraint.

Types of Vertical Centrifugal Pumps

Vertical centrifugal pumps come in various designs, each suited for specific applications. Below are the most common types of vertical centrifugal pumps:

1. Vertical Inline Pump

The Vertical Inline Pump is designed with the suction and discharge ports aligned in a straight line, which allows for easy installation in tight spaces. This pump is commonly used in HVAC systems, water distribution, and industrial cooling systems, where space is limited and efficiency is crucial.

2. Vertical Multistage Pump

A Vertical Multistage Pump features multiple impellers stacked vertically to generate higher pressures. It is ideal for applications requiring high-pressure outputs, such as water supply, boiler feed systems, and pressure boosting in marine applications.

3. Vertical Sump Pump

The Vertical Sump Pump is typically used to pump out liquid from sumps or pits. It is commonly found in wastewater treatment plants, bilge systems on ships, and other industrial drainage applications. Its vertical design allows it to handle corrosive and abrasive fluids effectively.

4. Vertical Turbine Pump

The Vertical Turbine Pump is primarily used for deep well pumping. This pump features a long shaft that extends into the well, drawing water from deep below the surface. It is commonly used in ship ballast systems, fire protection, and large-scale water distribution.

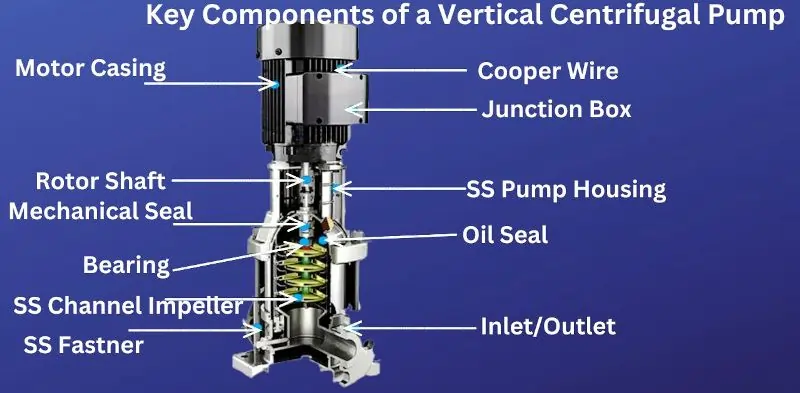

Key Components of a Vertical Centrifugal Pump

- Copper Wire

The copper wire is used for the winding in the motor, ensuring efficient electrical conductivity and minimal resistance loss. This high-quality winding is critical for the pump’s motor performance. - Junction Box

The junction box houses electrical connections and ensures safe and reliable wiring integration, protecting the electrical system from dust, moisture, and accidental contact. - SS Pump Housing

The stainless steel (SS) pump housing provides structural integrity and corrosion resistance, making it ideal for marine environments. It protects internal components from external factors like water, chemicals, and abrasion. - Oil Seal

The oil seal prevents the leakage of lubricants and the ingress of contaminants, ensuring smooth operation and extending the life of the pump’s internal parts. - Inlet/Outlet

These are the key ports where the fluid enters and exits the pump. The inlet allows for the suction of fluid, while the outlet channels the pumped fluid to the desired location. - SS Fastener

Stainless steel fasteners provide robust and corrosion-resistant connections for the assembly of the pump components. Their strength and durability are essential for long-term performance in harsh environments. - SS Channel Impeller

The stainless steel channel impeller is a crucial component responsible for imparting energy to the fluid. It rotates and creates the necessary flow and pressure within the pump system. - Bearing

Bearings support the rotational movement of the rotor shaft, ensuring smooth and frictionless operation of the pump. High-quality bearings reduce wear and increase the pump’s efficiency. - Mechanical Seal

The mechanical seal prevents leakage between the rotating shaft and the stationary housing, maintaining the pump’s pressure and ensuring reliability in demanding conditions. - Rotor Shaft

The rotor shaft transmits mechanical energy from the motor to the impeller, driving the pump’s operation. It is designed for durability and precision, ensuring effective energy transfer. - Motor Casing

The motor casing protects the motor’s internal components from external damage. It is typically constructed from high-strength materials to withstand environmental challenges and ensure the longevity of the pump.

How Does a Vertical Centrifugal Pump Work?

A vertical centrifugal pump operates by converting rotational energy, typically from a motor, into energy that moves the fluid. The pump’s design allows it to efficiently transport fluid in vertical applications such as in marine environments, industrial systems, or water treatment facilities. Here’s a step-by-step explanation of the flow dynamics inside the pump:

Step-by-Step Explanation of Flow Dynamics:

- Fluid Enters the Pump (Suction)

- The fluid enters the pump through the inlet located at the bottom of the pump. This happens due to a pressure differential created by the impeller’s rotation. The low-pressure area formed at the inlet causes the fluid to be drawn into the pump.

- Impeller Rotation

- Once inside, the fluid comes into contact with the stainless steel impeller. The impeller, driven by the rotor shaft, begins to rotate at high speed. This impeller is specifically designed to impart energy to the fluid, accelerating it radially outward from the center.

- Fluid Acceleration (Velocity Increase)

- As the impeller spins, it imparts kinetic energy to the fluid. The fluid gains velocity as it moves from the center of the impeller towards the outer edge. At this point, the velocity of the fluid reaches its maximum as the impeller blades guide the fluid outward.

- Conversion of Velocity to Pressure

- As the fluid moves outward, it passes through a volute casing or diffuser. Here, the high velocity of the fluid is gradually converted into pressure energy. This step is crucial in maintaining the pump’s efficiency because the pressure is needed to push the fluid to the desired height or destination.

- Fluid Exits the Pump (Discharge)

- The pressurized fluid exits the pump through the outlet located near the top. At this stage, the fluid’s pressure is at its highest, ready to be transported to its destination. The vertical design ensures that the fluid is efficiently discharged upwards, making the pump ideal for vertical fluid transfer.

Overview of Fluid Velocity, Pressure Changes, and Pump Performance:

- Fluid Velocity: The velocity of the fluid increases significantly as it moves through the impeller. This is crucial for the pump’s ability to impart energy to the fluid. The higher the impeller speed, the higher the fluid velocity.

- Pressure Changes: As fluid moves from the impeller to the outlet, the high velocity is converted into pressure. The centrifugal force generated by the impeller causes the pressure of the fluid to rise as it is pushed outward. The pump’s performance is directly tied to this pressure change—higher pressure results in better fluid displacement.

- Pump Performance Characteristics: The pump’s efficiency is determined by how well it converts motor energy into pressure and fluid velocity. Key performance factors include the flow rate, pressure head, and the impeller design. Vertical centrifugal pumps are optimized for high-pressure applications, making them suitable for moving fluids vertically in tall structures or systems.

Checks to Perform When Starting a Pump

Starting a pump requires several important checks to ensure safe and efficient operation. Below are the key checks to perform:

- Pump Priming

Ensure that the pump is primed (filled with liquid) to prevent dry running, which can damage the pump. - Check Valves and Lines

Verify that all suction and discharge valves are in the correct positions. The suction valve should typically be fully open, and the discharge valve should be slightly open to prevent backflow. - Lubrication

Ensure that bearings and other moving parts are properly lubricated to reduce friction and wear during operation. - Electrical Connections

Check that all electrical connections are secure and that the power supply is stable and within the pump’s rated voltage. - Coupling Alignment

Verify that the pump and motor couplings are correctly aligned to prevent vibrations and potential damage to the pump and motor. - Check for Leaks

Inspect the pump and pipework for any visible leaks that could affect performance or cause damage. - System Pressure and Flow

Check the system pressure and flow requirements to ensure they are within the pump’s operating range. - Safety Devices

Ensure all safety devices, such as pressure relief valves and overload protection systems, are functioning properly.

Applications of Vertical Centrifugal Pumps

Vertical centrifugal pumps are widely used across various industries due to their efficient design, reliable performance, and ability to handle high-pressure applications. These pumps are particularly well-suited for transferring fluids vertically, making them an essential component in systems where space and operational efficiency are critical. Below are some of the most common industrial applications of vertical centrifugal pumps:

1. Water Treatment Plants

Vertical centrifugal pumps are vital in water treatment plants for processes like water intake, filtration, and distribution. Their ability to handle large volumes of water and pump it vertically makes them ideal for transferring water from underground sources or reservoirs to treatment facilities and then distributing treated water to different locations.

2. Chemical Processing Plants

In chemical processing plants, vertical centrifugal pumps are used to transport chemicals and other fluids within the plant. These pumps are often constructed with corrosion-resistant materials to handle aggressive chemicals, acids, and solvents. Their precise flow control and ability to operate in confined spaces make them indispensable in maintaining continuous production in chemical processes.

3. Oil and Gas Industries

Vertical centrifugal pumps are heavily used in the oil and gas sector for pumping crude oil, refining processes, and transporting petroleum products. Their high-pressure capabilities allow them to move fluids over long distances, such as in offshore platforms or refineries. Additionally, their robust construction ensures they can withstand harsh environments and handle abrasive or viscous fluids typical in oil and gas operations.

4. Firefighting Systems

These pumps are commonly employed in firefighting systems, particularly in high-rise buildings and industrial facilities. Vertical centrifugal pumps ensure a steady supply of water under high pressure to extinguish fires effectively. They are often integrated into sprinkler systems and other emergency firefighting infrastructure, where reliability and fast response times are critical.

5. Marine Applications

Vertical centrifugal pumps are essential in marine applications for ballast water transfer, cooling water circulation, bilge pumping, and firefighting aboard ships. Their vertical design makes them space-efficient, which is especially beneficial in the limited space aboard ships. Additionally, their corrosion-resistant materials make them ideal for handling seawater and other marine fluids.

Advantages of Vertical Centrifugal Pumps

Vertical centrifugal pumps are known for their compact design, efficiency, and reliable performance, making them a preferred choice in various industrial applications. Below are some of the key advantages these pumps offer:

1. Space-Saving Design in Constrained Environments

One of the most significant advantages of vertical centrifugal pumps is their compact, vertical orientation. This design requires a smaller footprint compared to horizontal pumps, making them ideal for installation in spaces where horizontal real estate is limited, such as in high-rise buildings, ships, or crowded industrial facilities. Their vertical alignment allows them to fit seamlessly into tight spaces without compromising performance.

2. Ease of Installation in Vertical Configurations

Vertical centrifugal pumps are designed for easy integration into vertical piping systems, which simplifies the installation process. Their design eliminates the need for complex foundation setups or horizontal alignment checks. They are typically installed in-line with existing vertical piping, reducing the installation time and effort while providing straightforward maintenance access.

3. High Efficiency and Durability in High-Pressure Systems

Vertical centrifugal pumps are highly efficient when handling high-pressure fluid systems. Their design optimizes fluid movement, allowing for efficient energy transfer from the motor to the impeller, resulting in increased flow and pressure. Built with durable materials like stainless steel and corrosion-resistant components, these pumps are capable of withstanding harsh operating conditions, ensuring long-term reliability and minimal downtime in industrial environments.

Maintenance of Vertical Centrifugal Pumps

| Maintenance Aspect | Description |

|---|---|

| Preventive Maintenance Practices | – Regular Lubrication: Lubricate bearings and seals to reduce friction and wear. – Visual Inspections: Check for leaks, corrosion, and cracks. – Vibration Monitoring: Regularly monitor for unusual vibrations. – Pump Performance Monitoring: Track flow rate, pressure, and motor load to ensure efficiency. – Seal and Bearing Replacement: Replace seals and bearings periodically to prevent failures. |

| Common Problems | – Vibration: Caused by impeller imbalance, shaft misalignment, or worn bearings. Excessive vibration can damage pump components. – Cavitation: Vapor bubbles form due to low suction pressure and cause damage when they collapse. – Bearing Wear: Bearings wear out from friction, contamination, or lack of lubrication, leading to noise and pump failure. |

| Troubleshooting Techniques | – Vibration Issues: Check and tighten loose components, correct shaft misalignment, and rebalance impellers. – Cavitation: Increase suction pressure, clear any piping blockages, or adjust pump speed. – Bearing Failure: Replace worn bearings, ensure proper lubrication, and realign the shaft. – Loss of Flow or Pressure: Inspect the impeller for wear or blockages and check suction and discharge lines for obstructions or leaks. |

Performance Calculations for Vertical Centrifugal Pumps

Performance calculations are critical to ensuring that vertical centrifugal pumps operate efficiently and meet system demands. By using key formulas, engineers can determine important parameters like head, flow rate, and efficiency. Additionally, understanding pump curves is essential for selecting the right pump for a specific application. Below are the important calculations and explanations for these factors:

1. Key Formulas for Calculating Head, Flow Rate, and Efficiency

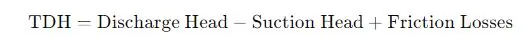

Total Dynamic Head (TDH)

Total Dynamic Head is the total equivalent height that a fluid is pumped, considering both the vertical lift and the friction losses in the system. It is a combination of the suction head and the discharge head:

- Discharge Head: The height the fluid must be pumped after it leaves the pump.

- Suction Head: The height difference between the fluid source and the pump inlet.

- Friction Losses: Losses due to friction in the piping, fittings, and other components.

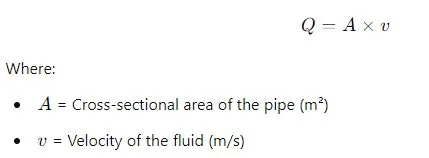

Flow Rate (Q)

The flow rate is the volume of fluid moved by the pump per unit of time, typically measured in cubic meters per hour (m³/h) or gallons per minute (GPM):

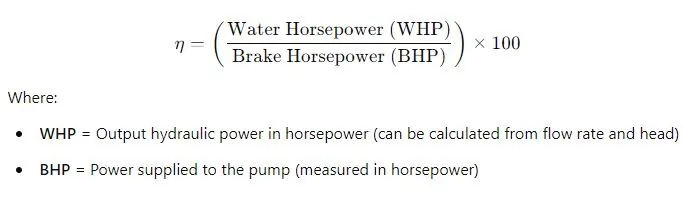

Pump Efficiency (η)

Efficiency is a measure of how well the pump converts mechanical energy into hydraulic energy. It is calculated by comparing the pump’s output power to its input power:

2. Explanation of Pump Curves and Their Significance

- Pump Curves

A pump curve is a graphical representation of a pump’s performance characteristics. It shows the relationship between the pump’s flow rate (Q) and head (H), and often includes efficiency, power consumption, and NPSH (Net Positive Suction Head) values.- Flow Rate vs. Head Curve: This curve indicates how much head a pump can generate at various flow rates. As flow increases, the head decreases, and vice versa. Knowing this relationship helps engineers determine if the pump can meet system requirements for both flow and pressure.

- Efficiency Curve: This curve shows how efficient the pump is at different flow rates. Maximum efficiency typically occurs at a specific point called the Best Efficiency Point (BEP). Operating the pump close to this point ensures optimal performance and reduces energy consumption.

- Power Curve: This curve indicates how much power the pump requires at different flow rates. It helps in selecting the correct motor size to avoid overloading or underutilizing the motor.

- NPSH Curve: This curve displays the Net Positive Suction Head Required (NPSHr) to prevent cavitation. Ensuring that the available NPSH (NPSHa) is greater than the required NPSH prevents cavitation, which can cause damage to the pump impeller and reduce efficiency.

3. Significance of Pump Curves

- Pump Selection: Pump curves help engineers select the right pump for a specific application by ensuring that the pump can meet the system’s required flow rate and head while operating at peak efficiency.

- Performance Monitoring: By comparing the actual pump operation to the pump curves, maintenance teams can identify if the pump is operating efficiently or if there are issues like cavitation, wear, or misalignment.

- Energy Efficiency: Operating a pump near its Best Efficiency Point (BEP) reduces energy consumption, minimizes wear and tear, and increases the pump’s service life.

Selecting the Right Vertical Centrifugal Pump

Selecting the appropriate vertical centrifugal pump for a specific application involves several critical considerations to ensure optimal performance, longevity, and efficiency. Factors such as flow rate, head requirements, fluid type, and installation space must be carefully evaluated. Additionally, understanding how to read and interpret pump datasheets is key to making an informed decision. Here’s a guide to help with the selection process:

1. Factors to Consider When Selecting a Vertical Centrifugal Pump

- Flow Rate

The flow rate is the volume of fluid that needs to be moved by the pump over a given time, usually measured in cubic meters per hour (m³/h) or gallons per minute (GPM). It is essential to select a pump that can meet or exceed the system’s required flow rate without operating under strain or inefficiency.

Tip: Always factor in potential future demand increases when determining flow rate needs. - Head Requirements

Head refers to the height or pressure the pump needs to overcome to move the fluid from one point to another. It includes both static head (vertical height difference) and friction head (losses due to friction in pipes and fittings). Ensure that the selected pump provides adequate head for your system’s needs.

Tip: Total Dynamic Head (TDH) calculations should include both vertical lift and friction losses to avoid under-sizing the pump. - Fluid Type

The type of fluid being pumped significantly impacts the choice of pump. Consider the fluid’s viscosity, corrosiveness, abrasiveness, and temperature. For example, highly corrosive or abrasive fluids require pumps made of materials like stainless steel or special coatings to prevent wear.

Tip: Verify the compatibility of all pump components (impeller, housing, seals) with the fluid type. - Installation Space

Vertical centrifugal pumps are often chosen for installations with limited horizontal space. However, it’s still crucial to assess the available vertical space and ensure the pump fits within the system’s layout. The pump’s footprint, height, and clearance for maintenance should all be factored into the installation plan.

Tip: Consider potential future expansions or modifications when evaluating installation space.

2. How to Read and Interpret Pump Datasheets

A pump datasheet contains valuable technical information necessary for selecting the correct pump. Here’s how to interpret key sections of a typical pump datasheet:

- Performance Curves

Most datasheets include performance curves, which provide the relationship between flow rate (Q) and head (H). These curves also show efficiency, power consumption, and Net Positive Suction Head Required (NPSHr).

Key Points to Interpret:- Flow vs. Head Curve: Ensure the pump can meet both the flow rate and head requirements of your system.

- Efficiency Curve: Identify the Best Efficiency Point (BEP) and aim to operate the pump close to this point for maximum efficiency.

- Power Curve: Ensure the selected pump’s power requirements match the motor’s capacity to avoid overloading.

- Materials of Construction

The datasheet lists the materials used in constructing the pump’s key components such as the impeller, pump casing, and seals. It’s important to check these materials for compatibility with the fluid being pumped.

Key Points to Interpret:- Stainless steel or specialty alloys for corrosive fluids.

- Hardened materials or coatings for abrasive fluids.

- NPSHr and NPSHa

The Net Positive Suction Head Required (NPSHr) value on the datasheet indicates the minimum pressure needed at the pump’s suction to avoid cavitation. Compare this value with the available NPSH (NPSHa) in your system to ensure sufficient suction pressure.

Key Points to Interpret:- NPSHa should be greater than NPSHr to avoid cavitation.

- Consider the piping system design to maintain the required suction pressure.

- Motor Specifications

The motor’s horsepower (HP), voltage, and speed (RPM) are typically specified in the datasheet. Ensure that the motor can handle the required load and that it operates within your system’s power supply parameters.

Key Points to Interpret:- Select a motor with sufficient power to avoid underperforming or overloading the pump.

- Match voltage and phase requirements with the electrical infrastructure.

- Dimensional Data

Datasheets provide detailed dimensions, including the height, width, and baseplate size. This information is essential for ensuring that the pump fits in the designated space and that there’s enough clearance for maintenance and operation.

Key Points to Interpret:- Verify that the pump’s dimensions fit your available installation space.

- Ensure there is access to key components for routine maintenance.

Conclusion

Selecting the right vertical centrifugal pump is crucial for ensuring efficient fluid handling in various industrial applications. By carefully considering factors like flow rate, head requirements, fluid type, and installation space, and understanding how to read pump datasheets, you can make informed decisions that optimize pump performance and longevity. A well-chosen pump not only meets operational demands but also enhances energy efficiency and reduces maintenance costs, making it a valuable asset for any system.

FAQ on “Vertical Centrifugal Pump”

Q: What is a vertical centrifugal pump?

A: It’s a pump that moves fluid vertically using centrifugal force.

Q: What is the principle of a vertical pump?

A: It converts motor energy into fluid movement via centrifugal force.

Q: When to use vertical pumps?

A: Use in tight spaces or for vertical fluid transport.

Q: What is the flow rate of a vertical pump?

A: Flow rates range from 8 to 45,000 m³/h (40 to 200,000 US gpm).