Exploring Vibration In Engine in Marine Diesel Engines

Marine diesel engines are like silent champions in various industries worldwide. These engines make boats move, produce electricity, power vehicles, and help with watering crops They’re incredibly important but also face a hidden problem that can mess with their performance: engine vibrations.

You might not believe it, but these vibrations can cause big problems for engines and even shake ships and buildings. Apart from the reasons for the effects above, these vibrations can damage the fuel systems making the engine noisy and unstable in operation.

In this blog post, we’ll talk a lot about vibrations to help you understand them more.. We’ll look at the different types of vibrations that can give these powerful machines a hard time. Our goal is to help you see why these vibrations matter.

But this will not be our limit. We will also explain the the troubles caused by these viberartionand the best tips to counter them. With this info, you can keep your marine diesel engine running smoothly and avoid costly issues.

This blog post is best for marine Engineers, Boat owners, and students curious to learn about vibrations. Join us as we unravel the mystery of engine vibrations and make marine diesel engines more reliable.

We’ll cover some crucial points:

Essential Guidelines: We’ll provide you with essential guidelines for dealing with vibrations in marine diesel engines. These guidelines will help you manage and understand these engine shivers better.

Types and Measurement: We’ll explain the different types of vibrations and how experts measure them. This knowledge is fundamental to grasp the basics of engine vibrations.

We’ll also touch upon:

Acceptable Levels: What’s okay and what’s not when it comes to vibrations in marine diesel engines? We’ll break down the acceptable levels, so you know when to be concerned.

Engine Components: We’ll explore the electrical and mechanical parts of the engines that are affected by these vibrations. It’s essential to see the bigger picture.

We won’t just rely on standards; we’ll also draw from real experience:

Past Knowledge: We’ll share insights from experienced colleagues who have dealt with engine vibrations.

45 Years of Experience: With 45 years of hands-on experience in marine and industrial engines, we’ll provide practical wisdom.

Our goal is simple: To set a standard that helps you tackle diesel engine vibrations effectively. We’ll explain where to place sensors to measure vibrations and how to interpret the results. So, let’s get ready to understand and conquer those engine vibrations!

Types of Vibration

In an engine, there are different types of vibrations that occur during its operation. These vibrations can be challenging to control completely because the engine has rotating parts and experiences firing and gas pressure, making its design quite complex. When vibrations get too close to the engine’s natural frequency, two significant issues can happen 1) Increased forces and 2) Catastrophic failure.

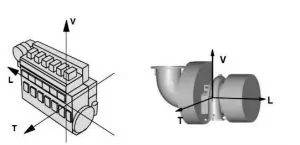

Different parts of the engine will experience varying levels of vibration. To understand and manage these vibrations, checks need to be carried out at various points and in different directions, such as longitudinal (front to back), transversal (side to side), and vertical (up and down).

The readings obtained from these checks should fall within normal limits. If they exceed these limits, further investigations and corrections are necessary to ensure the engine operates smoothly.

Now, let’s break down the three main types of engine vibrations:

Free Vibration in Marine Diesel Engines: This type of vibration occurs when the engine’s body is disturbed from its position, and it’s influenced by the engine’s natural frequency.

Forced Vibration in Marine Diesel Engines: Forced vibration happens when an external periodic force acts on the engine. The frequency of this vibration is directly related to the strength of the external periodic force.

Damped Vibration in Marine Diesel Engines: In damped vibration, the amplitude of vibration reduces with each cycle. This type of vibration is important to consider as it affects the engine’s performance and longevity.

Understanding these types of vibrations is crucial for maintaining the health of marine diesel engines and preventing potential issues that could arise from excessive vibration.

What are the 4 elements of vibration?

Understanding Vibration in 4 Simple Elements:

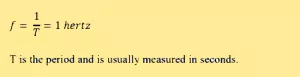

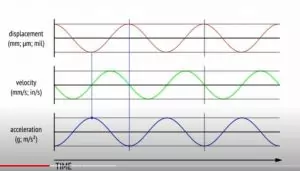

Frequency (F): Think of frequency as how fast something vibrates. It’s like counting how many times it goes back and forth or up and down in a second. High frequency means fast vibrations, like a buzzing bee, while low frequency is slower, like a swinging pendulum.

Displacement (D): Displacement shows how much something moves during vibration. It’s like measuring how far it goes from its resting position. A big displacement means it moves a lot, while a small one means it stays closer to where it started.

Velocity (V): Velocity tells you how fast something is moving during its vibration. It’s like checking its speed as it goes back and forth. High velocity means it’s moving quickly, while low velocity is slower.

Acceleration (A): Acceleration shows how quickly something is speeding up or slowing down during vibration. It’s like noticing if it’s getting faster or slower as it moves. High acceleration means it’s changing speed rapidly, while the low acceleration is steadier.

These four elements, F, D, V, and A, help us describe and understand vibrations in various things, from music to machines. They’re like the building blocks that scientists and engineers use to figure out how things move and behave when they vibrate.

What is the principle of vibration?

The Principle of Vibration for Engines in Simple Terms:

This principle tells us that engines, like everything else, vibrate. It’s because of how the engine’s parts move and work together. These vibrations can be small or big, fast or slow, and they affect how the engine runs.

Just like when we feel our heartbeats change with our emotions, an engine’s vibrations can change too. If something’s not right with the engine, it can vibrate in a way that’s not good. That’s why we want to make sure engines vibrate the right way, so they run smoothly and don’t break down.

Understanding the Causes of Marine Engine Vibration

Vibrations in diesel engines and generators can happen because of several important reasons:

- Misalignment: When the main engine and the alternator aren’t lined up properly.

- Unbalance: If there’s uneven weight or balance in the engine, the coupling (connecting parts), the vibration damper, or the alternator rotor. This happens because of irregular weight distribution, not the engine’s usual balance.

- Resonance: When certain combinations of the engine’s weight and stiffness make it vibrate more.

- Engine Firing: The engine’s cylinders try to twist the rotor.

- Misfiring: If some cylinders aren’t firing properly.

- Combustion Forces: Strong forces created when the engine burns fuel.

- Unbalanced Parts: When parts inside the engine that move back and forth aren’t balanced.

- Electromagnetic Forces: Forces related to electricity.

These factors can lead to vibrations in diesel engines and generators, which can affect how well they work.

Vibration due to Defects in Diesel Engines

Improper Tappet Clearance

Maintaining Valve clearance of diesel engines as per the OEM set values is essential. Valve clearance affects combustion and opening and closing of valves. Improper valve clearance will lead to severe defects. Excessive valve clearance will result in the valve’s late start and early closing.

The excessive valve clearance in the inlet valve will result in insufficient air supply to the combustion chamber. Insufficient air for the combustion will cause poor combustion leading to a low compression ratio, less power, improper combustion, less fuel economy after burning, and high carbon deposits inside the combustion chamber.

If an engine continues to run with excessive inlet valve clearance will result in power loss. A piston seizure may occur due to sticky piston rings with high carbon deposits.

Excessive valve clearance in the exhaust valve will lead to poor scavenging followed by knocking, heavy power loss, and high temperatures will lead to catastrophic failure of the Engine. The above phenomenon will severely impact the valve driving mechanism, causing heavy vibrations in the Engine.

Piston Slap

Engine power, reliability, durability, economy, and emissions are highly influenced by the tribological conditions of the cylinder liner and piston rings. The generation of engine noise and piston slap takes place by the piston mechanism. Piston slap is the primary source of transversal vibration in Diesel engines.

Harsh engine conditions are created due to the high piston speed. Under the condition of the boundary lubrication due to the contaminated lubricating oil and high external shock load, metal-to-metal between the piston and cylinder liner will take place. Under such conditions of piston slap, excessive oversized clearances will cause.

Impact forces between the piston and cylinder liner wall increase tremendously due to the excessive clearances accelerating in wear of moving parts. The piston slap and the piston ring clearance are interrelated. The intensity of the piston slap will be the source of high vibration.

Hence OEM recommendations for the measurement of clearances and change of related parts should be strictly adhered to control the Engine’s vibrations, excessive noise, and catastrophic failures.

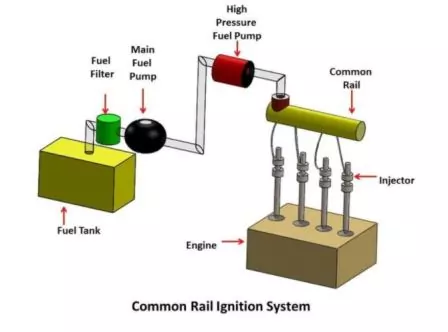

Faults in the fuel injection system

The fuel injection system is the Engine’s most crucial and controls the Diesel engine’s performance and reliability. The close examination of injection system conditions and fault diagnosis is the base of the fuel injection system function. A defective fuel injection system is responsible for the exhaust system’s power loss and increased pollutants. A higher fuel injection pressure will fuel consumption and increase emissions. A lower fuel injection pressure will decrease the engine power. A defective fuel injection pressure will cause poor fuel metering and poor fuel combustion.

A defective fuel injector will cause power loss due to improper combustion and high exhaust temperatures. Unbalanced power in each cylinder will result in increased engine vibrations.

The Implications of Engine Vibration

Vibrations in a marine diesel engine can cause various problems:

- More Stress: The engine has to work harder.

- Extra Wear: Parts wear out faster.

- Louder Noise: It gets noisier.

- Damage: Parts can get damaged quickly.

- Energy Loss: It uses more energy.

- Heavier Load: Bearings have to carry more weight.

All these things can make the engine break down.

Reducing Vibration in Marine Diesel Engines: Remedial Actions

Tip 1: Proper Engine Mounting

One of the primary steps in preventing engine vibration is to ensure proper engine mounting. Securely anchoring the engine to the vessel’s structure can significantly reduce vibration transmission. Using really good vibration mounts made for boats can make a big difference.

Tip 2: Balancing the Engine Components

To avoid shaking, parts like pistons, crankshafts, and propellers need to be balanced well. Imbalances can lead to significant vibrations that reverberate throughout the vessel. To fix this problem, you need to regularly check and balance things.

Tip 3: Regular Maintenance and Inspection

Taking care of your engine in advance and checking it often is super important. By regularly looking at things like engine parts, fuel systems, and exhaust systems, you can find problems early and avoid having to spend a lot of money on big repairs and downtime.

Tip 4: Use of Vibration Isolation Systems

You can put in special systems like flexible couplings and dampeners to soak up and get rid of vibrations. These systems work like cushions, making sure the vibrations don’t spread to other parts of the engine or the boat.

Tip 5: Quality Fuel and Lubrication

The kind of fuel and oil you put in your boat’s engine really matters. Good, clean fuel and the right oils can make the engine work better and not shake as much.

Vibration Measurement Locations (Points)

To measure vibrations in an engine, we focus on three points:

- The drive ends,

- The engine center, and

- The non-drive end of the crankshaft.

It’s crucial to do this when the engine is running and at its usual operating temperature.

We assess the strength of vibrations by considering three factors:

- Displacement (how much the engine moves),

- Velocity (the speed of this movement), and

- Acceleration (how quickly it happens).

We use a measurement called the RMS value to gauge the severity of these vibrations accurately.

Measure vibrations at various points on the engine, following the diagram.

- Also, measure vibrations in engine pumps and filters.

- Pay attention to the direction of each engine component:

- For the crankshaft, measure vibrations along its length (longitudinal).

- When checking the turbocharger, focus on vibrations along its length (longitudinal) as well.

This approach ensures that you assess vibrations correctly at different engine locations and components.

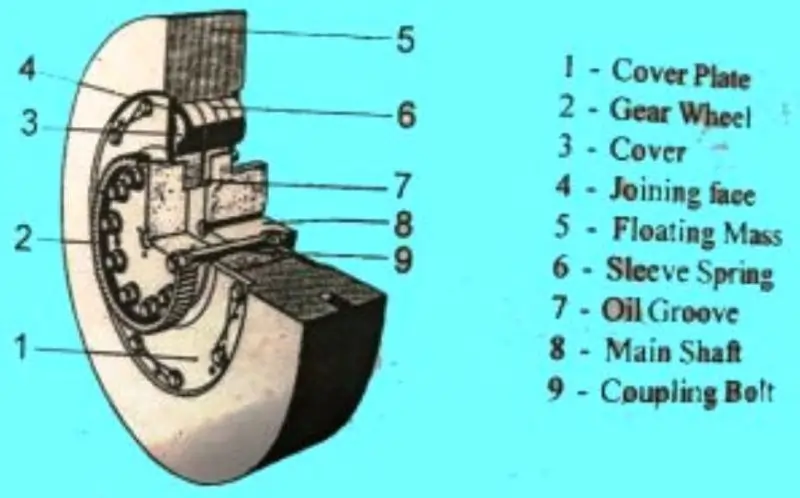

Vibration Damper

A vibration damper is like a special part installed at the non-drive end of the engine. Its job is to get rid of the twisting vibrations. This damper makes these vibrations smaller and less powerful.

This type of damper has two round parts connected by a bunch of spring-like things. These springs are filled with oil. The spinning part of the engine is connected to one of these round parts. The other round part tries to stop the vibrations from the spinning part.

When the engine moves, the upper round part moves along with it. This is normal and helps the engine work smoothly. But there’s a problem with this type of damper. The oil inside it gets hot because it has to absorb the vibrations. When the oil gets hot, it becomes less thick, and that can make the damper work less effectively.

Silicone Damper

A silicone damper is a different kind of damper that doesn’t use oil. Instead, it has a self-contained unit filled with silicone.

Here’s how it works:

- It has a lightweight casing that goes on the end of the crankshaft (the spinning part of the engine).

- Inside this casing, there’s a part that can move around freely.

- The space between this moving part and the casing is filled with silicone fluid.

- The silicone is thick and doesn’t change much when it gets hot.

- When the engine vibrates, this moving part with the silicone resists the vibration.

- It uses the thickness of the silicone to absorb the vibration energy.

- This keeps the engine running smoothly, and the moving part helps maintain a steady motion.

So, instead of using oil, this damper uses silicone to control engine vibrations.

What are the 5 modes of vibration?

The 5 Modes of Vibration in Simple Terms:

Asymmetric Mode: This is like a seesaw motion, where one side goes up while the other goes down. It’s not balanced.

Symmetric Mode: Imagine both sides moving together, like a synchronized dance. It’s balanced and equal.

Wagging Mode: Think of a dog wagging its tail from side to side. It’s a twisting motion.

Twisting Mode: This is like wringing out a wet cloth, where the ends twist in opposite directions.

Scissoring Mode: Picture two pairs of scissors opening and closing. The atoms move diagonally, like scissor blades.

FAQ on ” Vibration In Engine

Q: What causes vibrations in an engine?

A: Vibrations in an engine can be caused by imbalances, misalignments, and other factors.

Q: How can I reduce engine vibrations?

A: You can reduce engine vibrations by using vibration dampers and performing regular maintenance.

Q: Why are vibrations in an engine a problem?

A: Engine vibrations can lead to stress, wear, and even engine failure over time.

Q: Can engine vibrations affect a boat’s performance?

A: Yes, excessive engine vibrations can impact a boat’s performance and safety on the water.

Blog Conclusion

I hope the readers would have enjoyed the post and must have gained some input regarding Vibrations.. By knowing the types of vibration and why they happen, and by following the five tips we talked about in this article, plus using vibration dampers, you can put an end to engine vibrations at sea.