Voltage Transformers

Voltage transformers are crucial in modern electrical systems, ensuring efficient power distribution and voltage regulation. Understanding their role and functionality can empower professionals and enthusiasts alike to make informed decisions. In this post, you’ll gain seven powerful insights into voltage transformers, from their basic principles and types to the latest technological advancements and market trends. We’ll also delve into how to choose the right transformer, maintenance tips, and troubleshooting common issues. Whether you’re looking to expand your knowledge or make smarter choices, this comprehensive guide has got you covered.

Understanding Voltage Transformers

Definition and Function

Voltage transformers are essential electrical devices designed to convert electrical energy from one voltage level to another. Their primary function is to step up (increase) or step down (decrease) voltage levels to ensure safe and efficient power transmission and distribution. By transforming voltages, these devices facilitate the transmission of electricity over long distances and its utilization in various applications without significant energy loss.

Types of Voltage Transformers

| Type of Transformer | Description | Applications |

|---|---|---|

| Step-Up Transformers | Increase voltage from a lower level to a higher level. Typically used at power generation stations to elevate the voltage for long-distance transmission. | a. Power transmission from power plants to substations. b. High-voltage applications in industrial processes. |

| Step-Down Transformers | Decrease voltage from a higher level to a lower level. Used in the distribution network to lower the voltage for safe usage by consumers. | a. Distribution of electrical power to residential, commercial, and industrial consumers. b. Low-voltage applications in appliances and equipment. |

| Isolation Transformers | Provide electrical isolation between primary and secondary windings. Prevents direct electrical connection, enhancing safety and noise reduction. | a. Medical equipment for patient safety. b. Sensitive electronics to reduce electrical noise. c. Industrial machinery for operator protection. |

| Autotransformers | Single winding acting as both primary and secondary. More efficient and compact for voltage changes within a limited range. | a. Voltage regulation in industrial applications. <br> b. Audio systems for impedance matching. |

| Instrument Transformers | Include current transformers (CTs) and voltage transformers (VTs) for measuring electrical quantities. Step down high voltage/current to a lower, measurable level. | a. Metering and protection in high-voltage electrical systems. b. Relays and protection devices in substations. |

| Toroidal Transformers | Donut-shaped core providing higher efficiency and compact design. Often used in applications requiring low electromagnetic interference (EMI). | a. Audio equipment for minimal noise interference. b. Medical devices requiring compact and efficient transformers. |

| Oil-Filled Transformers | Use oil for cooling and insulation. Typically larger and used in high-power applications. | a. High-voltage power transmission. b. Large industrial equipment and power substations. |

| Dry-Type Transformers | Use air instead of oil for cooling. Safer for indoor applications where oil-filled transformers might pose a fire hazard. | a. Commercial buildings and high-rise structures. b. Indoor substations and industrial plants. |

Step-Up vs. Step-Down Transformers

- Step-Up Transformers are crucial for efficient power transmission over long distances, reducing energy losses by increasing the voltage.

- Step-Down Transformers make the high-voltage power suitable for end-use by reducing it to safer, usable levels.

Isolation Transformers

- Purpose: Provide electrical isolation between the input and output, ensuring safety by preventing direct electrical connection.

- Benefits: Enhances safety, reduces electrical noise, and protects against electrical shock.

Specialized Transformers

- Autotransformers: Efficient and cost-effective for applications requiring minor voltage changes, with a single winding serving dual purposes.

- Instrument Transformers: Essential for accurate measurement and protection in electrical systems, stepping down high voltage/current to lower levels for instruments and relays.

Applications

Voltage transformers are integral to various industries and applications:

- Power Transmission and Distribution: High-voltage transformers are essential in power plants and substations, stepping up the voltage for efficient transmission and stepping it down for safe distribution to residential, commercial, and industrial users.

- Manufacturing and Industrial Applications: Transformers are used in industrial machinery and equipment to match voltage levels to the operational requirements of different machines, ensuring safety and efficiency.

- Renewable Energy Systems: In solar and wind energy systems, transformers convert the generated power to suitable voltage levels for grid integration or local consumption.

- Medical Equipment: Isolation transformers are critical in medical devices and equipment, providing safety and reducing electrical noise that could interfere with sensitive diagnostic and treatment equipment.

- Electronics and Communication: Small transformers are used in electronic devices and communication systems to convert voltages and provide isolation, ensuring the proper functioning and safety of the devices.

Working of Voltage Transformers

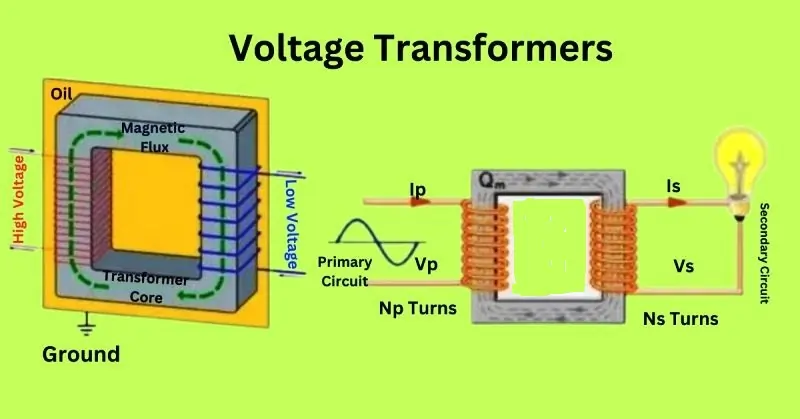

Voltage transformers operate based on the principles of electromagnetic induction, and their functionality can be understood through their key components and the relationships between them.

Components and Functionality

- Transformer: A transformer consists of two windings, the primary and the secondary, wound around a common core. The primary winding receives the input voltage (Vp), and the secondary winding delivers the output voltage (Vs).

- Primary Circuit (Ip and Vp):

- Ip: The current flowing through the primary winding.

- Vp: The voltage applied to the primary winding.

- Np Turns: The number of turns in the primary winding. This directly influences the transformer’s voltage transformation ratio.

- Secondary Circuit (Is and Vs):

- Is: The current flowing through the secondary winding.

- Vs: The voltage induced in the secondary winding.

- Ns Turns: The number of turns in the secondary winding. The ratio of Ns to Np determines whether the transformer steps up or steps down the voltage.

- Transformer Core: The core is typically made of laminated silicon steel to reduce eddy current losses and support efficient magnetic flux transfer between the windings.

- Magnetic Flux: When an alternating current (AC) flows through the primary winding, it creates a magnetic flux in the core. This flux links with the secondary winding, inducing an electromotive force (EMF) in it.

- Oil: Many large transformers are immersed in oil, which acts as an insulator and a coolant, preventing overheating and enhancing the transformer’s lifespan.

Working Mechanism

- Magnetic Induction: When an AC voltage (Vp) is applied to the primary winding, an alternating magnetic field is created in the transformer core. This alternating magnetic field generates a magnetic flux that flows through the core.

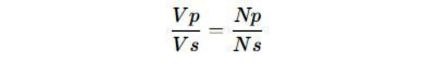

- Voltage Transformation: The voltage induced in the secondary winding VsV_sVs depends on the ratio of the number of turns in the secondary winding NsN_sNs to the number of turns in the primary winding NpN_pNp. This ratio determines whether the transformer will step up or step down the voltage. For example, if NsN_sNs is greater than NpN_pNp, the transformer steps up the voltage. Conversely, if NsN_sNs is less than NpN_pNp, the transformer steps down the voltage.

The magnetic flux induces a voltage in the secondary winding proportional to the ratio of the turns in the primary winding (Np) to the turns in the secondary winding (Ns). This is governed by the equation:

Depending on whether Ns is greater than or less than Np, the transformer will step up or step down the voltage.

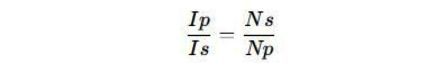

3. Current Transformation:

The current in the primary and secondary windings is inversely proportional to the voltage and number of turns, as per the equation:

This ensures that the power (P = V × I) remains constant (neglecting losses), thus conserving energy.

4. Output: The secondary circuit receives the transformed voltage (Vs), which can be either higher or lower than the input voltage (Vp), depending on the application’s requirements.

5. Grounding and Safety: In many applications, one side of the secondary winding is grounded to ensure safety and proper functioning of the electrical system.

Applications of Different Voltage Levels

- High Voltage Applications: Step-up transformers are used in power plants to increase voltage levels for efficient long-distance transmission, reducing energy losses.

- Low Voltage Applications: Step-down transformers are used in distribution networks to decrease voltage levels to safe, usable levels for homes and businesses.

Maintenance and Cooling

Oil Cooling: The oil used in transformers not only insulates the windings but also helps dissipate the heat generated during operation, ensuring the transformer operates efficiently and reliably over its lifespan.

Choosing the Right Voltage Transformer

| Factors to Consider | Description |

|---|---|

| Power Requirements | Determine the power capacity needed for your application, measured in kilovolt-amperes (kVA) or megavolt-amperes (MVA). Ensure the transformer can handle the load. |

| Voltage Levels | Identify the input (primary) and output (secondary) voltage requirements. This ensures compatibility with your electrical system and equipment. |

| Load Types | Consider the type of load (resistive, inductive, or capacitive) and the nature of the load (steady or variable). This affects the transformer’s design and selection. |

Brand Comparisons

| Brand | Unique Selling Points |

|---|---|

| ABB | Known for advanced technology and reliable performance. Offers a wide range of transformers for various applications, including smart transformers with IoT capabilities for improved monitoring and efficiency. |

| Siemens | Offers high-efficiency transformers with a focus on sustainability and energy savings. Known for innovative designs and robust construction, suitable for both industrial and utility applications. |

| General Electric (GE) | Provides versatile and durable transformers for diverse applications. Known for integrating cutting-edge technology and high-quality materials, ensuring long-term reliability and performance. |

| Schneider Electric | Focuses on energy-efficient and environmentally friendly transformer solutions. Known for user-friendly designs and advanced features that enhance operational efficiency and safety. |

| Eaton | Offers a broad range of transformers with a focus on reliability and performance. Known for excellent customer support and customizable solutions tailored to specific needs. |

User Reviews

| Brand | Key Feedback from Professionals and Consumers |

|---|---|

| ABB | Professionals praise ABB for their innovative technology and reliable performance in demanding applications. Consumers appreciate the long lifespan and robust construction, although some note the higher initial cost. |

| Siemens | Users highlight the energy efficiency and durability of Siemens transformers. Professionals value the advanced features and ease of integration into existing systems, while some consumers mention the premium pricing as a consideration. |

| General Electric (GE) | GE transformers receive positive feedback for their versatility and strong build quality. Professionals appreciate the integration of modern technology, while consumers find them reliable and durable, with occasional comments on the size and weight. |

| Schneider Electric | Known for their eco-friendly and efficient designs, Schneider Electric transformers are praised for their user-friendly features and reliable performance. Users appreciate the excellent customer service and support. |

| Eaton | Professionals and consumers alike commend Eaton for their customizable solutions and dependable performance. The ease of installation and robust support network are frequently mentioned as significant advantages, though some users note a longer lead time. |

Latest Innovations and Technological Advancements in Voltage Transformers

| Innovation | Description | Examples and Benefits |

|---|---|---|

| Smart Transformers | Integration with smart grids and IoT (Internet of Things) technology, allowing real-time monitoring, predictive maintenance, and enhanced control over the power network. | Real-Time Monitoring: Provides continuous data on transformer health and performance, enabling predictive maintenance and reducing downtime. Enhanced Control: Improves grid stability and efficiency by allowing operators to make informed decisions based on real-time data. Examples: ABB’s TXpert and Siemens’ Sensformer are leading examples of smart transformers. |

| Efficiency Improvements | Advances in materials and design to enhance energy efficiency, reduce losses, and improve overall performance. | Amorphous Core Transformers: Utilize amorphous steel, which has lower hysteresis losses compared to traditional silicon steel, leading to higher efficiency. High-Efficiency Insulation: New insulation materials that improve thermal performance and reduce dielectric losses. Examples: Hitachi Energy’s Eco-efficient transformers and Schneider Electric’s Green Transformers. |

| Future Trends | Predictions for future technological developments in voltage transformers, focusing on sustainability, advanced materials, and enhanced integration with renewable energy sources. | Sustainable Solutions: Increasing focus on environmentally friendly designs, such as the use of biodegradable insulating fluids and materials with lower environmental impact. Advanced Materials: Development of new core materials and superconducting transformers that offer significantly lower losses and higher efficiency. Renewable Integration: Enhanced compatibility with renewable energy sources, including improved performance in fluctuating conditions and better grid integration. Examples: Development of biodegradable oils by Cargill and the adoption of superconducting materials by research institutions and industry leaders. |

Detailed Descriptions

- Smart TransformersIntegration with Smart Grids and IoT:

Smart transformers are equipped with sensors and communication interfaces that enable them to connect with smart grids and IoT platforms. This integration allows for real-time monitoring of parameters such as temperature, load, and voltage levels. Advanced analytics can predict potential failures and optimize maintenance schedules, reducing operational costs and improving reliability. For instance, ABB’s TXpert and Siemens’ Sensformer are designed to provide actionable insights and facilitate seamless integration with modern smart grid infrastructure. - Efficiency Improvements

- Amorphous Core Transformers: Traditional transformers use silicon steel cores, which have higher hysteresis losses. Amorphous core transformers, however, use a non-crystalline structure that significantly reduces these losses, resulting in higher efficiency. These transformers are particularly beneficial in applications where reducing energy losses is critical.

- High-Efficiency Insulation: Advances in insulation materials have led to better thermal management and lower dielectric losses. These improvements enhance the overall performance and lifespan of transformers. Companies like Hitachi Energy and Schneider Electric are at the forefront of developing and implementing these high-efficiency solutions.

- Future Trends

- Sustainable Solutions: There is a growing emphasis on making transformers more environmentally friendly. This includes the use of biodegradable insulating fluids, which reduce the environmental impact in case of leaks or disposal. Additionally, efforts are being made to develop transformers with lower carbon footprints by using sustainable materials and processes.

- Advanced Materials: The development of superconducting materials holds promise for the future of voltage transformers. These materials have negligible electrical resistance, which can drastically reduce energy losses and increase efficiency. Although still in the experimental stage, superconducting transformers could revolutionize the industry.

- Renewable Integration: As the demand for renewable energy sources like solar and wind increases, transformers need to adapt to the unique challenges posed by these variable power sources. Future transformers will likely feature enhanced capabilities to handle fluctuations and integrate more seamlessly with renewable energy grids.

Market Trends and Forecasts for Voltage Transformers

Current Market Overview

- Market Size: The global voltage transformer market was valued at approximately USD 20 billion in 2023. This market encompasses various types of transformers used in different applications, from power generation and transmission to industrial and residential use.

- Major Players: Leading companies in the voltage transformer market include ABB, Siemens, General Electric (GE), Schneider Electric, and Eaton. These companies dominate the market with their extensive product portfolios, technological advancements, and strong global presence.

Growth Projections

- Expected Growth: The voltage transformer market is projected to grow at a compound annual growth rate (CAGR) of around 6% from 2024 to 2030. By 2030, the market is expected to reach USD 30 billion, driven by increasing demand for electricity, modernization of existing infrastructure, and the integration of renewable energy sources.

- Emerging Markets: The Asia-Pacific region, particularly China and India, is anticipated to experience significant market growth. Rapid industrialization, urbanization, and infrastructure development in these countries are key factors contributing to the rising demand for voltage transformers.

Investment Opportunities

- Renewable Energy Integration: With the global shift towards renewable energy, there is a growing demand for transformers that can efficiently integrate with solar, wind, and other renewable energy sources. Investment in this area can lead to innovative solutions that enhance grid stability and efficiency.

- Smart Grids: The development of smart grids requires advanced transformers equipped with IoT capabilities. These smart transformers allow for real-time monitoring, predictive maintenance, and better control over power distribution, presenting a lucrative investment opportunity.

- Eco-friendly Solutions: As environmental concerns rise, there is an increasing focus on developing sustainable and eco-friendly transformer technologies. Investment in biodegradable insulating fluids, amorphous core transformers, and other green technologies can drive innovation and meet regulatory requirements.

Maintenance and Troubleshooting for Voltage Transformers

Routine Maintenance

- Visual Inspections: Regular inspections help identify signs of wear, oil leaks, corrosion, and other physical damages that could indicate potential issues. Ensuring the transformer’s exterior and surrounding environment are in good condition can prevent many problems.

- Oil Testing: Transformers with oil insulation require regular oil testing. Dielectric tests check the oil’s insulating properties, while dissolved gas analysis can detect early signs of internal arcing, overheating, and insulation breakdown.

- Electrical Testing: Regular insulation resistance and power factor tests help monitor the electrical integrity of the transformer. These tests can identify insulation degradation and other issues that may not be visible through a simple inspection.

- Cleaning: Keeping the transformer and its surroundings clean helps maintain efficient cooling and reduces the risk of fire and contamination. Regular cleaning prevents the buildup of dust and debris, which can affect the transformer’s performance.

Common Issues

- Overheating: Transformers can overheat due to inadequate cooling, high ambient temperatures, or overload conditions. Ensuring proper ventilation, maintaining cooling systems, and monitoring load levels can mitigate overheating issues.

- Insulation Degradation: Insulation materials can degrade over time due to thermal, electrical, and environmental stresses. Regular testing and timely replacement of degraded insulation help maintain the transformer’s reliability and prevent failures.

- Electrical Faults: Faults in windings, connections, or other electrical components can cause performance issues or failures. Regular electrical testing can detect these faults early, allowing for timely repairs or replacements.

- Noise: Unusual noises can indicate mechanical issues, loose components, or core problems. Identifying and addressing the source of the noise can prevent further damage and ensure the transformer operates quietly and efficiently.

Safety Protocols

- Personal Protective Equipment (PPE): Wearing appropriate PPE, such as insulated gloves, safety glasses, and other protective gear, is essential for protecting personnel from electrical hazards during maintenance activities.

- Lockout/Tagout Procedures: Ensuring the transformer is de-energized and locked out before maintenance prevents accidental energization and reduces the risk of electrical shock or injury.

- Training: Proper training in transformer maintenance and safety protocols is crucial for all personnel involved. This includes understanding how to perform maintenance tasks safely and recognizing potential hazards.

- Emergency Procedures: Having clear procedures for handling emergencies, such as electrical shocks or fire, ensures that personnel can respond quickly and effectively, minimizing injury and damage.

Conclusion

Voltage transformers are vital components in modern electrical systems, playing a crucial role in efficient power distribution and voltage regulation. By understanding their operational principles, types, and applications, you can make informed decisions about their use and maintenance. Keeping up with the latest innovations and market trends ensures you stay ahead in an evolving industry. Regular maintenance and troubleshooting, coupled with strict adherence to safety protocols, can significantly extend the lifespan and reliability of these essential devices. Whether you’re a professional or an enthusiast, the insights provided in this guide will help you harness the full potential of voltage transformers in your applications.

FAQ on “Voltage Transformers”

Q: What is the primary function of a voltage transformer?

A: To step up or step down voltage levels for efficient power distribution.

Q: What are the common types of voltage transformers?

A: Step-up, step-down, isolation, autotransformers, and instrument transformers.

Q: How do smart transformers integrate with smart grids?

A: They use IoT technology for real-time monitoring and enhanced control.

Q: What routine maintenance is required for voltage transformers?

A: Visual inspections, oil and electrical testing, and regular cleaning.