What Causes Oil Pump Failure

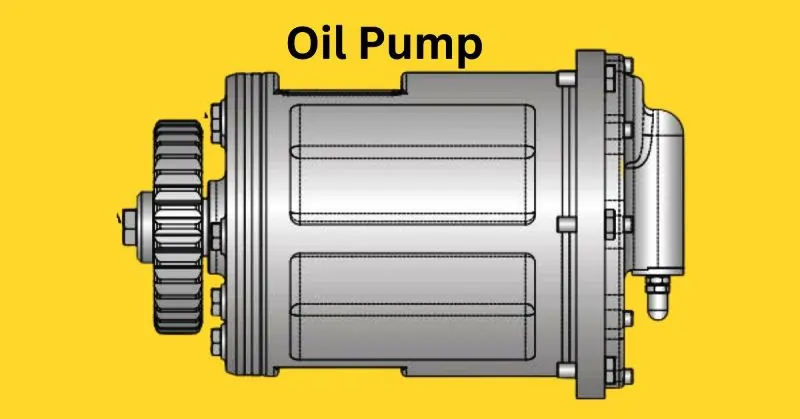

An oil pump is a part of the engine that circulates oil throughout the engine. The oil pump is the most important part of an engine, which helps in pumping the lube oil for the lubrication Crankshaft, Camshaft, and Bearings.

The Lube oil pump is installed on the rear side of the engine on the cylinder block. The lube oil pump gets driven from the Crankshaft through gears. It has a series of gears or vanes that rotate and draw oil from the oil pan. The oil is then pumped through the oil filter and circulated throughout the engine.

A spring-loaded relief valve maintains the lube oil pressure in the system. The pressure is adjusted at the prescribed pressure from the Manufacturer,

With a failed Lube oil pump in an engine, all the moving parts will be starving of the Lube oil and there will be a major seizure of moving parts leading to major damage.

Normally Lube oil pump maintenance is overlooked during maintenance of the engine.

6 Critical Reasons to Know

1. Lack of Regular Maintenance

A Lube oil pump needs to be maintained at regular intervals. Normally pump overhauling is done during the engine overhaul. Manufacturers club the engine parts overhauling during the major overhauls.

If during the engine overhauls, the pump’s overhaul is neglected, then there could be a major failure of the engine parts.

During the pump overhauls, Bearin and bushes are changed. Internal vanes or gear clearances are checked and the worn-out parts are replaced as per the results of inspections after cleaning of the components.

2. Oil Quality and Viscosity

The kind of oil you put in your engine really matters. If it’s not the right type or quality, or if you don’t change it regularly, bad things can happen to your oil pump.

An oil change is scheduled during overhaul or if the lube oil reports do not meet the specified criteria. Every engine manufacturer supplies the data in their maintenance manual. These specified data are to be maintained. The engines running on HFO need more attention than the engines running on Diesel and Petrol. TBN plays a major role in the engine running on HFO. TBN value decides the quality of the oil. The properties have been discussed in detail in our other post on Types Of Lubrication: 5 Vital Methods for Ensuring Smooth Operations

So, to keep your engine and oil pump happy, use the right oil and make sure to change it on time. It’s like giving your engine a refreshing drink to keep everything running smoothly.

3. Overheating

All engine parts including the oil pump will be in big problem with overheating. The oil pump is responsible for circulating oil throughout the engine to keep its moving parts lubricated and prevent them from overheating. Oil will break and lose its properties due to overheating.

The oil pump is also susceptible to damage from the formation of harmful sludge. Sludge is a thick, oily substance that can form in the engine when the oil is not changed regularly or when the engine is not properly maintained. The delicate passageways of the oil pump can become clogged with sludge, preventing appropriate operation.

4. Contaminants in the Oil

The oil pump is designed to circulate clean, pure oil throughout the engine. However, dirt, metal shavings, or even gasket material can find their way into the oil system. These contaminants can damage the oil pump in a few ways:

- They can abrade the pump’s moving parts, causing them to wear out prematurely.

- They can clog the pump’s passages, preventing it from circulating oil properly.

- They can damage the pump’s seals, causing it to leak oil.

If the oil pump is damaged by contaminants, it will fail and cause serious damage to the engine.

Here are some ways to prevent contaminants from entering the oil system:

- Change the oil and oil filter regularly. This will remove dirt and debris that have accumulated in the oil.

- Inspect the engine regularly for leaks. Leaks can allow contaminants to enter the oil system.

- Use the correct type of oil and oil filter. The wrong type of oil or oil filter can allow contaminants to enter the oil system.

- Have the engine serviced regularly by a qualified mechanic. A mechanic can inspect the engine for leaks and other problems that can allow contaminants to enter the oil system.

5. Wear and Tear

As your engine ages, its mechanical components naturally wear out. This is because they are constantly moving and rubbing against each other. The oil pump is no exception. The bearings, gears, and seals in the oil pump can all wear out over time.

When these parts wear out, they can cause the oil pump to fail. For example, if the bearings wear out, the oil pump will not be able to rotate properly. This can cause the gears to jam or the oil pump to leak.

To help prevent oil pump failure due to wear and tear, it is important to have your engine oil pump inspected regularly. This will allow the mechanic to identify any worn parts and replace them before they cause a problem.

6. Low oil levels:

The oil pump takes the suction from the engine sump and circulates oil throughout the engine to keep its moving parts lubricated and prevent them from overheating. If the oil level in the engine is too low, the oil pump will not be able to take the suction and will not be able to circulate enough oil to lubricate the engine properly. The pump will fail due to the lack of lubrication in the pump’s bearing, bushes, and gears.

FAQs

Q: Can using special oil help the oil pump?

A: Yes, good quality oil helps the oil pump work better and lasts longer.

Q: How often should I change my car’s oil to keep the oil pump happy?

A: It’s best to change the oil every 3,000 to 5,000 miles to make sure everything runs smoothly.

Q: Can using synthetic oil help prevent oil pump failure?

A: Yes, synthetic oil is known for its high quality and consistent viscosity, which can reduce strain on the oil pump

Q: What are the warning signs of impending oil pump failure?

A: Look out for low oil pressure warnings on your dashboard, engine knocking sounds, or increased engine temperature.

Conclusion

In conclusion, it is crucial to keep your Engine oil pump intact, It is of utmost importance to keep the pump maintained as per the maintenance schedule. In the event of any abnormality like a fall in lube oil pressure, high temperatures, and any obnoxious noise from the engine especially the pump side. The overhauling of the lube oil pump is to be carried out by an experienced marine fitter/technician. All the critical components like bearings, bushes gear, and seals are to be renewed as per the inspection results.

1 thought on “What Causes Oil Pump Failure: 6 Critical Reasons to Know”

Comments are closed.