Turbocharger in Diesel Engine

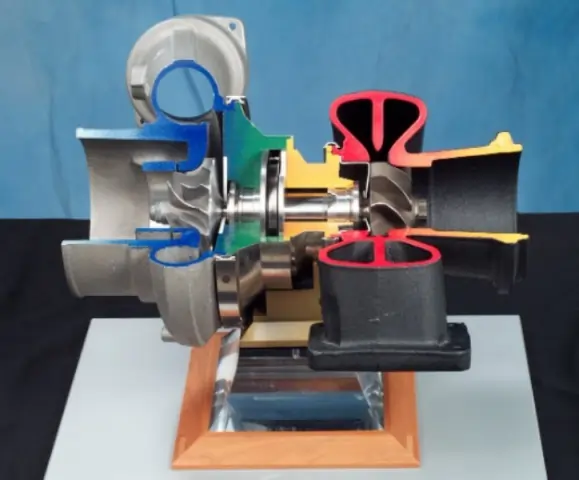

A turbocharger is an engine component that increases its power output by compressing the air that flows into the combustion chamber. It is composed of two main parts: a compressor and a turbine that is connected by a shaft. The engine’s exhaust gases power the turbine while the compressor sucks in the air and compresses it before it enters the combustion chamber. This compressed air allows more fuel to be burned, increasing power output. Turbochargers are popularly used in performance vehicles, trucks, and diesel engines to improve fuel efficiency and power.

Benefits of using a turbocharger

Adding a turbocharger to a marine diesel engine brings a sea of benefits:

Enhanced Engine Power: By forcing more air into the engine, a turbocharger dramatically increases the engine’s power. This leads to a more robust and responsive performance on the water.

Greater Fuel Efficiency: Turbocharged marine engines use fuel more effectively. They draw more energy from each drop, translating into improved fuel economy for longer voyages.

Lower Emissions: A turbocharger helps the engine burn fuel more completely. This means boats emit fewer pollutants, contributing to cleaner marine environments.

High-Altitude Performance: At high altitudes, where air is scarce, a turbocharger compensates by compressing available air, ensuring the engine’s power doesn’t drop off.

Boosted Towing Power: With a turbocharger, marine engines gain extra muscle, which helps tow or push through heavy currents or maneuver large loads.

Overall, turbocharging a marine diesel engine maximizes efficiency, power, and environmental compatibility, ensuring a smooth sail in calm and challenging conditions.

How a Turbocharger Works

Basic principles of a turbocharger

A turbocharger operates based on the principles of thermodynamics and fluid mechanics. It consists of two main components, the turbine and compressor, which are joined by a shaft. The turbine is situated in the exhaust system, which is powered by the hot, high-pressure exhaust gases produced by the engine. As these gases pass over the turbine blades, they rotate the turbine.

The compressor is located on the opposite end of the shaft and is driven by the turbine. As the turbine spins, it rotates the compressor, which draws in ambient air and compresses it before it enters the combustion chamber of the engine. This compressed air enables more fuel to be burnt, leading to increased power output.

The design and size of the turbine and compressor influences the turbocharger’s efficiency. Larger turbines and compressors can provide more boost, but they require more exhaust energy to power up. Smaller turbines and compressors can offer faster response times but with less gain. The performance of the turbocharger is also affected by the design of the compressor housing and turbine vanes, which determine its efficiency and operating range.

In summary, a turbocharger is a complicated system that functions on the principles of fluid dynamics and energy transfer. It boosts an engine’s power and efficiency.

Different types of turbochargers and how they work

There are several types of turbochargers, each with unique features and operating principles. Here are some of the most common types:

Constant Pressure Turbocharger

A constant-pressure turbocharger is a type of turbocharger that is designed to maintain a consistent level of boost pressure throughout the engine’s operational range. This is achieved through a wastegate that regulates the flow of exhaust gas to the turbine, controlling the turbine’s speed and the amount of boost produced.

An electronic or mechanical actuator regulates the wastegate in the constant pressure turbocharger system, responding to changes in the engine’s RPM and load. The wastegate opens to bypass more exhaust gas and reduce boost pressure under heavy loads. On the other hand, it closes to allow more exhaust gas to flow through the turbine and increase the boost pressure under lighter loads.

The constant-pressure turbocharger system provides a consistent boost pressure level throughout the engine’s operational range, resulting in smooth power delivery and improved drivability. It also prevents engine damage by preventing the boost pressure from exceeding safe levels. Constant-pressure turbochargers are commonly used in modern high-performance engines, particularly in applications that require precise boost control and smooth power delivery, such as in racing and sports cars.

Pulse Type Turbocharger

A Pulse Type Turbocharger, also known as a Twin-Scroll Turbocharger, optimizes the exhaust gas flow to improve engine efficiency and responsiveness. In this system, exhaust gas is directed through two separate channels or “scrolls” that are isolated from each other until they reach the turbine. The exhaust pulses are isolated and timed for optimal turbine efficiency, reducing back pressure that can occur in traditional turbocharger systems.

A common shaft still connects the turbine and compressor, but the compressor is designed to optimize the compressed air flow from each scroll for more efficient and responsive boost pressure. Pulse-type turbochargers are commonly used in high-performance engines where quick throttle response and smooth power delivery are critical, such as in racing and sports cars.

Variable Geometry Turbocharger (VGT)

A Variable Geometry Turbocharger (VGT) is designed to improve engine efficiency and power by changing the size and shape of the turbine housing based on the engine’s operating conditions. It can adjust the size of the exhaust gas inlet and the angle of the turbine blades, allowing it to optimize the exhaust gas flow and boost pressure for different engine speeds and loads.

An electronic or mechanical actuator controls the VGT system by adjusting the position of the turbine vanes. VGT provides better engine response and efficiency across a broader RPM range than a traditional fixed geometry turbocharger. It results in improved acceleration, lower emissions, and better fuel economy. VGTs are commonly used in modern diesel and gasoline engines, particularly in applications where high torque and low RPM power are critical, such as in heavy-duty trucks and SUVs.

Sequential Turbocharger

A Sequential Turbocharger is a turbocharging system commonly used in high-performance engines that utilizes two or more turbochargers of different sizes arranged in series. One of the turbochargers is designed to operate at low engine speeds, while the other is designed to operate at high engine speeds.

The smaller turbocharger generates boost pressure at lower engine RPMs and can spool up quickly, while the larger turbocharger provides more boost pressure at higher RPMs. The actuator, controlled electronically or mechanically, engages the larger turbocharger when the engine reaches a certain RPM threshold. This ensures that the engine is continuously operating at optimal performance levels and prevents turbo lag.

Sequential turbochargers are popular in high-performance sports cars and racing engines, as they can significantly increase power and torque output without sacrificing responsiveness or drivability. However, sequential turbocharging systems can be complex and expensive to design and manufacture, and they may require additional cooling and lubrication systems to handle the increased heat and stress generated by the system.

Electric Turbocharger

An Electric Turbocharger, also known as an Electric Supercharger, is a forced induction system that uses an electric motor to power the compressor of a turbocharger rather than relying on exhaust gas flow to drive the turbine. The compressor is driven by an electric motor integrated into the turbocharger housing or installed separately.

Unlike traditional turbochargers, electric turbochargers can provide instant boost pressure, improving engine response and acceleration, as there is no waiting time for the exhaust gases to drive the turbine. They are more efficient than traditional turbochargers since they don’t need exhaust gas energy to drive the turbine. However, electric turbochargers can generate heat and require additional cooling systems to prevent component damage. They can also be more expensive to manufacture and install.

Benefits of Using a Turbocharger

A turbocharger provides several benefits to an engine, including:

- Increased Power: A turbocharger forces more air into the engine, allowing it to burn more fuel and produce more power.

- Improved Fuel Efficiency: With a turbocharger, the engine can extract more energy from the same amount of fuel, resulting in improved fuel efficiency.

- Reduced Emissions: Turbocharging can help reduce emissions by allowing the engine to burn fuel more efficiently, producing fewer harmful pollutants.

- Improved High Altitude Performance: At high altitudes, the air is less dense, which can reduce an engine’s power output. However, a turbocharger can help compensate for this by forcing more air into the engine.

- Better Performance Across RPM Range: A turbocharger can increase power and torque across a broader range of engine speeds, resulting in better overall performance and drivability.

- Downsizing: Turbochargers can be used to downsize the engine, allowing it to produce the same power as a larger engine while consuming less fuel and taking up less space.

- Increased Durability: Turbochargers can help reduce engine stress by providing more power with less effort, resulting in improved durability and longevity.

Factors to Consider Before Installing a Turbocharger

Before installing a turbocharger, there are several factors to consider, including:

- Compatibility: Not all engines are compatible with turbochargers. It’s essential to ensure that the engine is designed to handle the increased stress and power output that a turbocharger can provide.

- Cost: Turbochargers can be expensive to purchase and install, so it’s essential to factor in the overall cost of the system, including any necessary modifications or upgrades to the engine.

- Maintenance: Turbochargers require regular maintenance, including oil changes and cleaning or replacement of the air filter. It’s important to consider the cost and time required for maintenance.

- Driving Habits: How the vehicle is driven can affect the performance and longevity of a turbocharger. Aggressive driving can stress the engine and turbocharger, increasing the risk of damage or failure.

- Cooling System: Turbochargers generate a significant amount of heat, so it’s important to ensure that the engine’s cooling system can dissipate the extra heat generated by the turbocharger.

- Warranty: Installing a turbocharger can void the vehicle’s warranty, so it’s important to consider the potential impact on the warranty and any extended warranties or service plans.

- Local Laws and Regulations: It’s important to consider any local laws and regulations regarding modifications to the engine or exhaust system before installing a turbocharger.

5 Ways to Boost Your Engine’s Power with a Turbocharger

Here are 5 ways to improve your engine’s power with a turbocharger:

- Upgrade the Turbocharger: Replacing the stock turbocharger with an upgraded unit can increase power. Larger turbochargers can provide more boost pressure and more air to the engine, resulting in more power.

- Install an Intercooler: Adding an intercooler can cool the compressed air before it enters the engine, increasing its density and providing more power. This is especially important for turbocharged engines that generate a lot of heat.

- Increase Boost Pressure: Boost pressure can be increased to provide more air to the engine, resulting in more power. However, it should be done carefully to avoid damaging the engine.

- Upgrade the Fuel System: The turbocharger increases the amount of fuel being burned in the engine, so upgrading the fuel system can ensure that the engine is receiving enough fuel to maximize power output.

- Engine Tuning: Tuning the engine can optimize its performance and power output. Upgrading the air intake, exhaust system, fuel injectors, and ignition system can help improve performance and take full advantage of the turbocharger’s capabilities.

Pros and Cons of Using a Turbocharger

Maintenance and Upkeep of a Turbocharged Engine

Maintenance and upkeep are crucial for the longevity and optimal performance of a turbocharged engine. Here are some tips for maintaining and keeping your turbocharged engine in good condition:

- Follow the manufacturer’s recommended maintenance schedule: Make sure to follow the recommended maintenance schedule for your vehicle, which includes regular oil changes, air filter replacements, and other essential maintenance tasks.

- Use high-quality oil: Use a high-quality oil recommended by the manufacturer for your turbocharged engine. This is important because turbocharged engines generate higher temperatures and require oil that can withstand the heat.

- Allow the engine to cool down: After driving your turbocharged engine, let it cool down before shutting it off. This helps to prevent heat buildup and premature wear and tear on the engine and turbocharger.

- Check the turbocharger for leaks: Check the turbocharger regularly for leaks, which can cause loss of power and engine damage. If you notice any leaks, have them repaired immediately.

- Avoid excessive heat: Avoid putting excessive stress on your turbocharged engine by avoiding extended periods of high-speed driving, racing, or towing heavy loads. This can cause the engine to overheat and lead to premature wear and tear.

- Use high-quality fuel: Use high-quality fuel that is recommended by the manufacturer for your turbocharged engine. This can help to prevent damage to the engine and turbocharger and improve performance.

- Have the turbocharger inspected: Have the turbocharger inspected periodically by a qualified mechanic to ensure it is functioning properly and to detect any potential issues before they become major problems.

Our Best Picks on Turbochargers

Garrett Powermax GTP38R Ballbearing Turbocharger

The Garrett Powermax GTP38R Ballbearing Turbocharger is a high-performance aftermarket turbocharger designed for Ford Power Stroke diesel engines. It features a ball bearing design, which provides faster spool-up and improved throttle response. The compressor wheel is 88mm in diameter, larger than the stock compressor wheel, allowing for increased airflow and improved power output. The turbine wheel is also larger, at 72mm in diameter, and is made of Inconel for improved durability.

The turbocharger is designed to work with modified engines that have increased fuel delivery and exhaust modifications and can provide up to 600 horsepower and 1000 lb-ft of torque. It is also designed to be a direct replacement for the stock turbocharger, making installation easier for those with mechanical experience.

Blog Conclusion

In conclusion, turbocharging is a popular method of boosting an engine’s power, providing several benefits such as increased power, improved fuel efficiency, reduced emissions, better high altitude performance, better performance across RPM range, downsizing, and increased durability. However, there are also potential drawbacks to consider, such as increased cost, added complexity, and the need for careful installation and maintenance. Before installing a turbocharger, it’s important to consider factors such as the engine’s design, intended use, and budget, and to explore all options for optimizing engine performance. Ultimately, with the right approach, a turbocharger can be a valuable tool for unlocking an engine’s full potential.

Frequently asked questions on Turbochargers

Read our related posts

- The Best 10 tips on Turbocharger Surging concept

- Turbocharger Bearing Lubrication System: The best 10 tips on

- How To Clean Turbocharger Blower and Turbine Sides on Ship?

- Diesel Engine Governors: Best 10 Tips on How to Maintain

- Turbo Failure Symptoms: 5 Signs You Mustn’t Neglect in Marine Engines

- Turbo Surging | 23-24 The Best Review on

- How Does A Turbo Work: Unveiling the Power of Boost