Table of Contents

Turbo Surging

The high vibration with audible obnoxious noise emerging from the compressor end of the turbocharger is known as Turbocharger surging. During the breakdown of gas flow scavenge air reversal happens through a diffuser and impeller blades to the blower side causing the surging. Surging is a heavy mass of airflow resulting in vibration in the Turbocharger compressor impeller and vanes. During this process, the compressor operates abnormally and produces a very high-pitched noise which is called a Turbocharger surging.

Take immediate action to eliminate the Turbocharger surging, since surging affects the combustion process of the Engine. Prolonged surging will cause thrust-bearing damages due to the production of abnormal axial thrusts

Unveiling the Reasons Behind Turbocharger Surging

- Uneven distribution of power in the Engine. Cylinders produce unbalanced power. In this process, the air requirement for the turbochargers will differ and cause surging.

- The compressor wheel and turbine nozzle ring fouled severely.

- Chocked exhaust manifold

- Inclement weather.

- Reduction of Air through the compressor wheel

- The air filter and silencer were chocked with dirt.

- High backpressure after the exhaust manifold results in a drop in turbine speed

- Fouled charge air cooler

- High cooling water temperature at a Cooler

- Choked nozzle ring

- Load fluctuation

- Engine speed fluctuation

Effective Ways to Prevent Turbocharger Surging

- Carry out the periodic cleaning of air filters, Charge air cooler

- Carry out the water washing and granule cleaning of the turbine side and compressor side as per the prescribed schedule

- Perform the complete maintenance of the turbocharger as per the OEM recommendations

- Periodically perform the shoot blowing of Waste heat recovery boiler

- Check the Pmax of the engine while recording the EPD engine performance data measurement.

Steps to Take When Turbocharger Surging Occurs

- Reduce the engine speed

- Check the loading pattern of the engine. If the load is frequently varying, then try to stabilize the uniform load

- Look for the fire on the Exhaust and scavenge the air side of the engine.

- Check the air pressure manometer for any fouling of the air filter

- Check the Coolant temperature of the charge air cooler.

- Carry out the water washing of the compressor side

- Perform the granule cleaning of the turbine side

If Surging Continues: Next Steps to Consider

- Inspection of the Turbocharger nozzle ring. If damage to blades or abnormal wear down of blades, then change the nozzle ring.

- Inspection of the Compressor wheel. Clean the compressor wheel

- Cleaning of Charge air cooler. Dismantle the charge air cooler and carry out the manual chemical cleaning of the cooler on-air and waterside

Impact of Surging

The following components will suffer damage due to the prolonged surging

1. Fracture in compressor wheel due to vibrations

2. Cracks in Turbine blades

3. Overheating of the bearings

4. Damage to the filter and silencer.

What is the surge limit of a turbocharger?

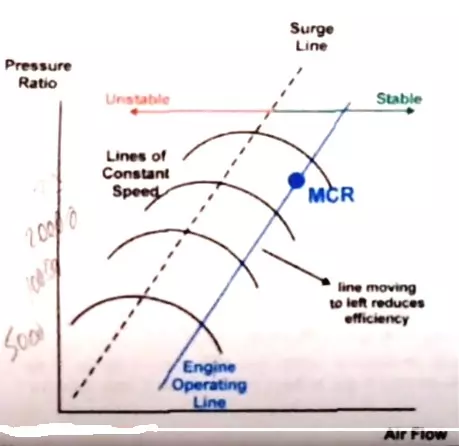

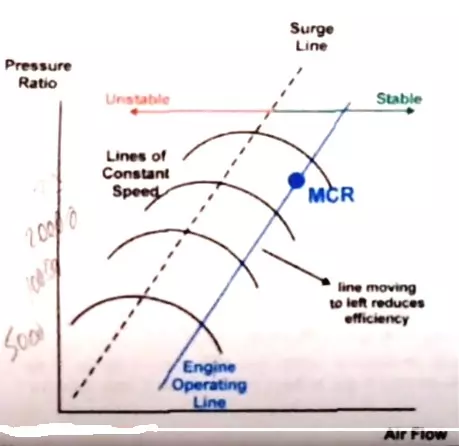

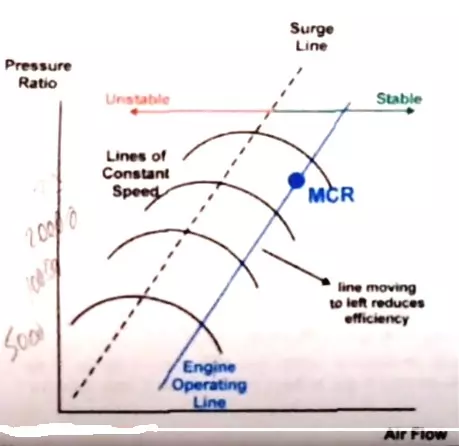

The surge limit of a turbocharger is like a safety line for the engine. It’s the point where the turbocharger can’t give the engine any more air. The compressor surge limit defines the maximum boost pressure for a given air mass flow. Surge limits the maximum boost pressure which can be achieved by the turbocharger compressor in the low-speed engine region. If it goes beyond this limit, the turbocharger can start making strange noises and the engine’s performance might drop. So, staying within this limit is important to keep everything running smoothly. Think of it as the turbocharger’s comfort zone, where it works best without getting overwhelmed. The engine’s stationary performance and the maximum torque limit are depicted in Figure

Evaluation Criteria for Turbocharger Performance

- Output and speed of the engine

- The temperature of the intake air

- Before and after turbine exhaust temperatures

- Charge air pressure

- Lube oil Temp.

- Lube oil pressure

- Compressed scavenge air Temp.

- Charge air temperature after the cooler

- Speed of the turbocharger

- Pressure loss in the air filter

Maintenance Schedule for Turbocharger Care

Every 8000- 12000 running hour

- Complete dismantling of the turbocharger

- Measurement of clearances as per the Instruction manual

- Carry out the cleaning of the compressor and turbine casing, Inspect for any cracks and erosion/corrosion marks

- Cleaning and blowing through the ports of the bearing casing

- Clean and inspect for cracks and erosion on the nozzle ring.

- Inspection and assessment of rotor and bearing parts

Every 36000 running hours

- Repeat the maintenance work as per the 8000 to 12000 running hour schedule.

- Replace the bearings ( use the genuine bearing )

Understanding the Importance of Turbocharger Speed Variations

Drop-in Turbocharger speed

- Damaged bearings and rotor components

- Connection of defective cylinders during the pulse operation of the turbocharger

- Leaky or faulty exhaust manifold or charge air ducting.

Increased Turbocharger speed

Dirty turbine

Precaution

Let the engine idle at least for 10 to 15 minutes for the lubricating oil to flow in the turbocharger to dissipate the temperature in the turbocharger bearings

Compressor cleaning during operation

Wet cleaning of the compressor is only for cleaning the compressor with clean water and is subject to permission from the engine manufacturer.

The density of the dirt deposit will depend upon the cleanliness of the atmospheric air. The dirt deposit on the compressor wheel will be due to the following elements in the air.

- Oily mist

- Solid combustion substances

- Different kinds of other dust particles.

An adverse effect of the above elements will be on the compressor efficiency and reduction in charge air pressure.

Due to the above negative, effects there will be a rise in exhaust temperature and elevated fuel consumption. The deposition of dirt will also cause the rotor to unbalance.

Compressor cleaning should be carried out between 25 to 100 engine running hours, depending on environmental conditions

Cleaning Method

Wet cleaning of the compressor wheel is strict as per the Turbocharger manufacturer’s guidelines. All the turbocharger manufacturers approve the wet cleaning method since the technique is easy and safe. In this method, water is injected into the compressor wheel from a built-in injection pipe. In this process, water use is not to act as a solvent but to create a mechanical impact of the drops on the compressor wheel. This process is the most suitable process for moderate dirt deposits. For cleaning the advanced dirt deposits, follow the OEM guidelines.

Procedure for Cleaning Turbine Blades and Nozzles During Operation

The combustion process of heavy fuels creates the accumulation of dirt on turbine blades and nozzle rings. The following products of combustion are responsible for the deposits.

- Ash/soot

- Cinders

- Un-burnt fuel Sodium vanadate vanadyl

An increase in dirt deposits requires proper cleaning. If not cleaned, it will cause an increase in charge air pressure, reduce turbine efficiency, and increase engine temperatures. Engine out will be affected. Heavy deposits will also cause the turbine rotor to unbalance.

Follow the guidance for the cleaning method from Turbocharger manufacturer instruction manuals.

Differences Between Turbo Stall and Surge

In simple words, turbo stall and surge are two different issues in a turbocharger. Stall happens when the airflow gets disrupted sideways, while surge happens when the airflow is disrupted front and back. When a turbocharger stalls, the airflow is uneven, but in the surge, the airflow might even reverse in a pulsating manner.

Blog Post Conclusion

Inwrapping, it is crucial, and handling the Surging problem is to be taken seriously. This helps keep engines running well and lasting a long time. The engine will become less efficient and might suffer damage if continues unattended. But if we know why surging happens, how to prevent it, and what to do when it occurs, we can protect our engines and prevent any harm.

Doing regular maintenance and sticking to maintenance schedules is a big part of stopping turbocharger surging. By following the instructions from the makers and keeping an eye on how well the engine is doing, we can catch and fix surging problems early.

The way turbochargers change speed is really important too. If we pay attention to speed changes and adjust them carefully, we can make sure the engine works great and prevent surging from happening.

People who run engines should know what causes surging, how to stop it, and what to do if it happens. By being aware of all this, engines can run smoothly, costs for fixing things can be lower, and the engines can be more dependable.

FAQ on ” Turbo Surging”

Q1: What is turbo surging?

A1: Turbo surging is when a turbocharger makes strange noises and the engine’s performance is affected.

Q2: What causes turbo surging?

A2: Turbo surging can be caused by things like air blockages, worn-out parts, or incorrect settings.

Q3: How can turbo surging be prevented?

A3: Regular maintenance, clean air filters, and proper settings can prevent turbo surging.

Q4: What should I do if I notice turbo surging?

A4: If you notice turbo surging, it’s best to check for the causes and get the issue fixed by a professional.