2 stroke marine diesel engine lubrication

Lubrication is critical to the smooth operation of marine engines, ensuring that moving parts work efficiently and reducing friction, wear, and heat. Marine engines, especially those operating in harsh environments, rely heavily on robust lubrication systems to maintain performance and longevity. In marine propulsion, both 2-stroke and 4-stroke engines have distinct lubrication requirements.

A 2-stroke engine uses a dual lubrication system, one for the crankcase and another for the cylinder liner, while a 4-stroke engine employs a single system for both components. This key difference highlights the complexity of 2-stroke engine lubrication, where the cylinder oil is separately injected to handle high heat and corrosion in the combustion chamber. Understanding the differences between these systems is essential for efficient maintenance and engine care in marine applications, as each system has unique demands to ensure optimal performance and reliability.

Lubrication of Two-Stroke Marine Engine

In a two-stroke marine engine, lubrication plays a crucial role in ensuring the smooth operation of moving parts by reducing friction, minimizing wear, and preventing excessive heat build-up. Unlike four-stroke engines, two-stroke engines have separate systems for lubricating the crankcase and the cylinder liner. The cylinder oil is injected directly into the combustion chamber to lubricate the area between the piston and cylinder liner, while crankcase oil circulates through the engine’s bearings and other moving components. Proper lubrication is essential for maintaining engine performance and extending the engine’s operational life.

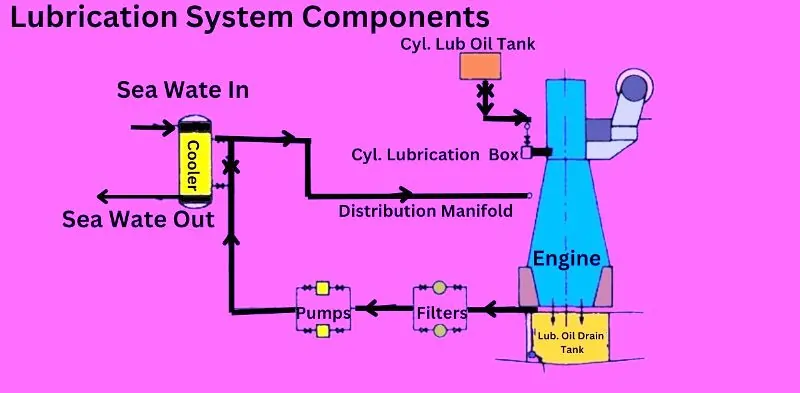

Components of the Lubrication System

Main Engine Sump

The sump is the reservoir located beneath the engine that stores the crankcase oil. After lubricating the moving parts, the oil returns to the sump to be reused.

Lube Oil Pump

The lube oil pump draws oil from the sump and circulates it to the necessary engine components. Centrifugal pumps are commonly used to ensure high flow rates.

Lube Oil Cooler

The oil cooler removes excess heat from the oil, preventing the engine from overheating and maintaining optimal performance.

Filter

A fine mesh filter with 50-micron precision is used to remove impurities from the lube oil, ensuring that contaminants do not cause wear or damage to the engine parts.

Cylinder Oil Tank

The cylinder oil tank stores highly basic oil (with a Total Base Number of 40-100) that lubricates the piston and cylinder liner. This oil is not reused and is specially formulated to withstand high heat and acidic conditions in the combustion chamber.

Working of Lubrication in Main Engine

The lubrication system in a two-stroke marine engine is designed to ensure that all critical engine components receive a continuous supply of oil to reduce friction, dissipate heat, and prevent wear. This system works in a step-by-step process, with the oil flowing from the sump to the various parts of the engine through pumps, filters, and coolers, ensuring optimal performance and longevity of the engine.

Lubrication Process

Step 1: Oil Pumped from the Sump

The lubrication process begins with the lube oil pump, which draws oil from the main engine sump. The sump serves as a reservoir, collecting oil that has already passed through the engine components.

Step 2: Circulating Through the Lube Oil Cooler

Once the oil is pumped from the sump, it passes through the lube oil cooler. The cooler removes excess heat from the oil, ensuring that it maintains the proper temperature before it is circulated to the engine components. This step is vital for preventing engine overheating.

Step 3: Filtering to Remove Contaminants

Before reaching critical engine parts, the oil flows through a filter designed to remove impurities and contaminants. The fine mesh filter (usually 50 microns) ensures that the oil is free of debris, preventing engine wear and damage caused by particles.

Step 4: Cylinder Oil Injection

In two-stroke engines, cylinder oil is separately injected into the combustion chamber to lubricate the piston and cylinder liner. This oil is specifically formulated to handle the extreme temperatures and corrosive conditions in the chamber. Unlike crankcase oil, cylinder oil is not reused and is designed for single-use lubrication.

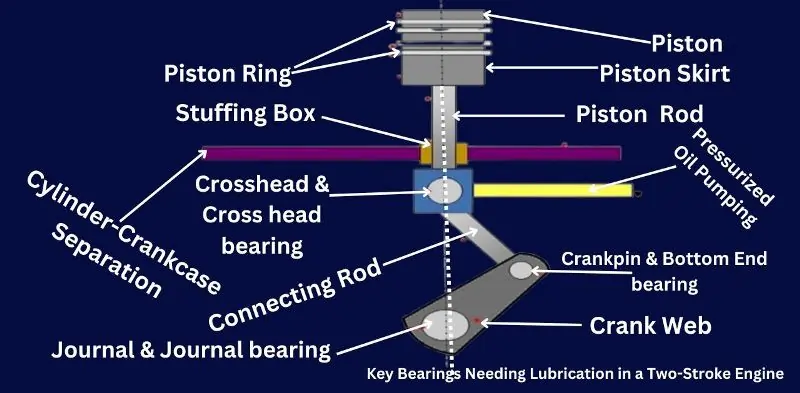

Key Bearings Needing Lubrication in a Two-Stroke Engine

Bearings play a vital role in the operation of a two-stroke marine engine, as they support key components and facilitate smooth movement. To prevent excessive friction, wear, and heat, these bearings must be consistently lubricated. In a two-stroke engine, three key bearings require particular attention for lubrication: the crosshead bearing, crank-pin bearing, and main bearing.

Crosshead Bearing

Function:

The crosshead bearing connects the piston to the connecting rod and transmits the force generated by the combustion process without applying any sideways thrust on the crankshaft. This design allows the piston to move vertically without causing excessive lateral stress on the crankshaft.

Importance:

Lubrication of the crosshead bearing is critical to ensure smooth movement and prevent wear due to the high forces it transmits. Proper lubrication also minimizes friction and extends the service life of the bearing.

Crank-Pin Bearing

Function:

The crank-pin bearing connects the crankshaft to the connecting rod, allowing the transmission of power from the piston’s linear motion to the rotational movement of the crankshaft.

Importance:

The crank-pin bearing endures heavy loads and high rotational speeds, making continuous lubrication essential. Adequate lubrication reduces wear and prevents overheating, ensuring that the bearing can handle the mechanical stresses of the engine’s operation.

Main Bearing

Function:

The main bearing supports the crankshaft and allows it to rotate smoothly within the engine. It is one of the most critical bearings in the engine as it carries the crankshaft’s weight and the forces transmitted from the piston.

Importance:

Proper lubrication of the main bearing is crucial to reduce friction and heat generated by the crankshaft’s rotation. By minimizing wear and maintaining a smooth operational surface, lubrication helps ensure the long-term reliability and efficiency of the engine.

Components of Lubricating Oil System in Two-Stroke Marine Engine

The lubrication system in a two-stroke marine engine comprises several vital components, each serving a critical function in ensuring smooth engine operation and longevity. These components work together to maintain optimal lubrication, reduce friction, and protect the engine from wear and overheating.

Main Engine Sump

The main engine sump serves as the reservoir for crankcase oil. It collects oil that has circulated through the engine and allows it to settle before being pumped back into the system. The sump ensures that an adequate supply of oil is always available for lubrication.

Lube Oil Pump

The lube oil pump is responsible for pumping oil from the sump to the engine’s various moving parts. Typically, a centrifugal pump is used due to its ability to handle high flow rates efficiently. The pump ensures that oil reaches all necessary components under controlled pressure, facilitating smooth engine operation.

Lube Oil Cooler

The lube oil cooler is essential for maintaining the engine’s operational temperature. As the oil circulates through the engine, it absorbs heat from the moving parts. The cooler removes this excess heat, preventing overheating and ensuring that the oil maintains its lubricating properties.

Filter

The filter plays a crucial role in preventing contaminants from entering the lubrication system. A fine mesh filter, usually 50 microns, removes impurities such as metal particles and debris from the oil, protecting the engine from damage and wear.

Cylinder Oil Tank

The cylinder oil tank stores a different type of oil used specifically for lubricating the cylinder liner and piston. Unlike crankcase oil, which is reused, cylinder oil is injected directly into the combustion chamber and is not recycled. Cylinder oil is more basic (with a higher Total Base Number) to neutralize the acidic environment inside the combustion chamber, ensuring effective protection of the piston and liner.

Comparison with Four-Stroke Engine Lubrication

The lubrication systems in two-stroke and four-stroke marine engines differ significantly in their design and function, primarily due to the unique demands of each engine type.

In two-stroke engines, there are two distinct lubrication systems: one for the crankcase and another for the cylinder liner. The crankcase oil lubricates the moving parts, such as bearings and the crankshaft, while cylinder oil is separately injected into the combustion chamber to lubricate the piston and liner. This separate system introduces added complexity, as the cylinder oil is not recycled and must be continuously replenished. The cylinder oil also has a higher Total Base Number (TBN), typically ranging from 40 to 100, to neutralize the acidic environment in the combustion chamber caused by fuel combustion.

In contrast, four-stroke engines use a single lubrication system that serves both the crankcase and cylinder components. The oil is circulated through the engine and then returned to the sump for reuse, simplifying the system. The oil in four-stroke engines generally has a lower TBN compared to two-stroke engines, as it is not exposed to the same level of acidity.

The complexity of two-stroke lubrication, with its separate oil systems and higher TBN values, ensures more specialized care for the engine components but also requires more frequent monitoring and oil replenishment compared to four-stroke engines.

FAQ on 2-Stroke Marine Diesel Engine Lubrication

Q- What is the lubrication of a 2-stroke diesel engine?

A- The lubrication system in a 2-stroke diesel engine separates crankcase oil and cylinder oil to reduce friction and wear.

Q- Which lubrication system is used in a marine engine?

A- Marine engines use a combination of crankcase lubrication and cylinder oil injection in 2-stroke engines.

Q- What lubricates a 2-stroke engine?

A- A- Crankcase oil lubricates moving parts, while cylinder oil lubricates the piston and liner.

Q- What oil is used in a 2-stroke engine?

A- 2-stroke engines use cylinder oil with a high Total Base Number (TBN) and crankcase oil for bearings and gears.

Conclusion

Proper lubrication is essential for maintaining the performance and longevity of marine engines. It minimizes friction, reduces wear, and prevents overheating, ensuring smooth operation. In 2-stroke engines, the dual lubrication system—with separate oils for the crankcase and cylinder—adds complexity but provides specialized care for key components. In contrast, 4-stroke engines use a simpler single system where oil is reused. Understanding these differences is crucial for efficient engine maintenance and performance optimization in marine applications.