Table of Contents

Working Of 4 Stroke Diesel Engine With Diagram

In the world of ships and the sea, the power source that keeps everything running smoothly is the Four-Stroke Diesel Engine Working. Think of them as the silent heroes, specifically designed to work as generators for ships. They make sure the lights stay on and all the systems operate seamlessly while out at sea. Unlike regular gasoline engines, ships rely on these diesel generators because they are both efficient and dependable.

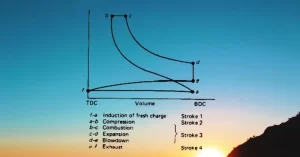

Imagine this engine’s process as a kind of rhythmic dance. It all starts with what’s called the “intake stroke,” where the engine takes a breath by pulling in air through a special valve. Then comes the “compression stroke,” where the engine squeezes the air really tight, creating the heat needed to make the diesel fuel catch fire, without using spark plugs. This ignition starts a powerful movement that drives the ship’s systems forward. The “exhaust stroke,” like a big exhale, gets the engine ready for the next round.

But what’s really cool is how carefully the fuel is put into the compressed air, making sure it burns just right. This efficiency, along with the engines being tough and having a lot of twisting force (called torque), makes them super important for anything that happens at sea. From ships carrying stuff to ones carrying people, these marine four-stroke diesel engines, working as generators, keep everything going with their reliable power.

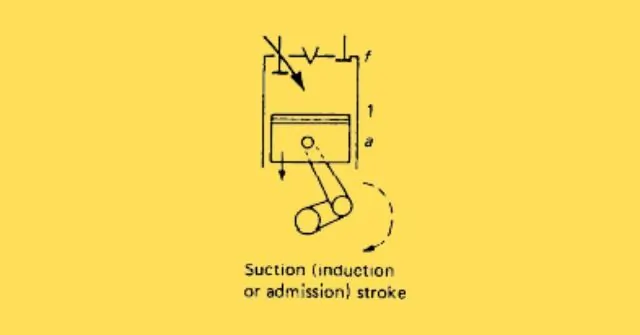

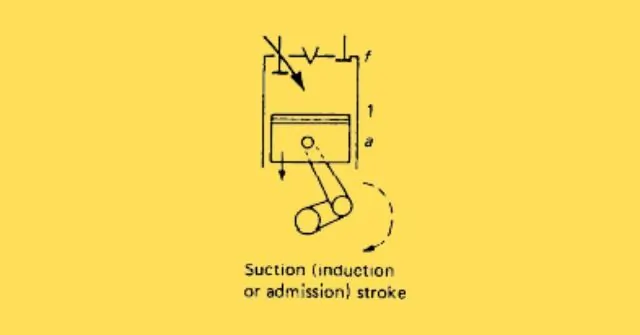

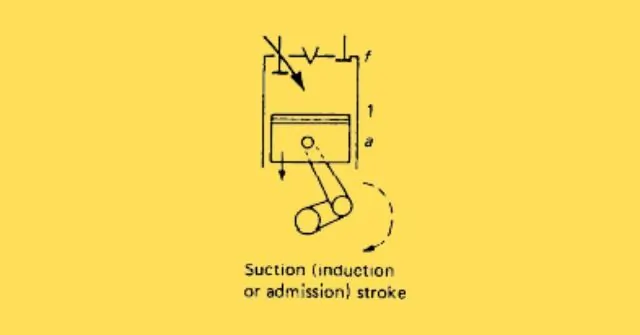

Phase 1: Breathing In -Suction stroke

28 Deg before the movement of the piston in the exhaust stroke, the inlet valve starts to open, and the Intake stroke starts from this moment, and the Exhaust valve is still in open condition. The flow of exhaust gases will create a suction effect and the fresh charges will start to suck in.

The piston continues its upward moment TDC; the fresh charges will enter and exhaust gases leave. Ta about 12 deg after TDC the exhaust valve will start to close. The exhaust valve closes fully at about 22 degrees AFTDC (After the Top dead Centre) The time during inlet valve and exhaust valve are open is known as the Valve overlap period. In this case valve overlap period will be 50 Deg. The cool air keeps the engine parts cool. After the piston passes the Top dead center, fresh charges keep coming in due to the suction effect in naturally aspirated engines and with force in supercharged engines. This stroke is known as an induction/ suction stroke.

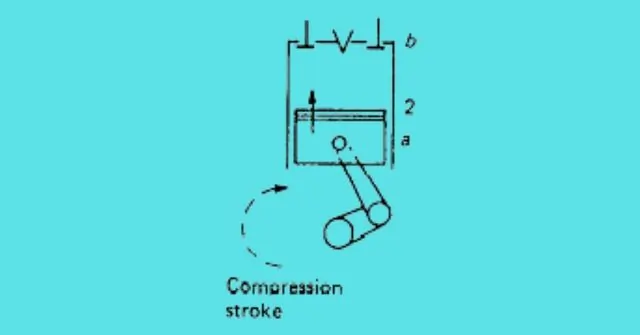

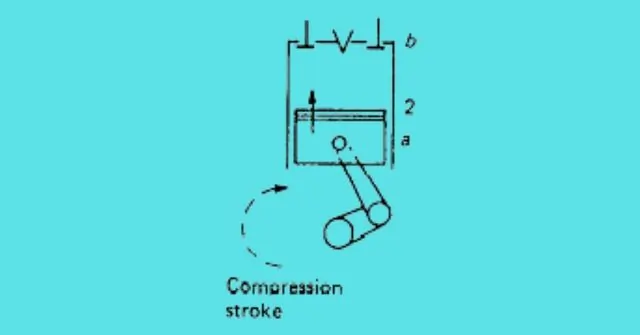

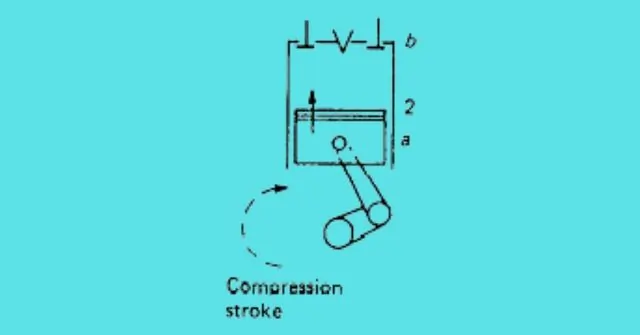

Phase 2: Squeezing – Compression Stroke

The inlet valve starts to close at 35 deg after the Bottom dead center and it is in a fully closed position at 43 Deg after the bottom dead center. Charge air is at normal pressure and temperature. As the piston moves upward the pressure and temperatures keep rising.

Fuel injection starts at 10 to 20 Deg before TDC. Injection fuel gets ignited due to the ignition temperature.

In this stroke inlet valve closes and the upward movement of the piston compresses the air in the cylinder.

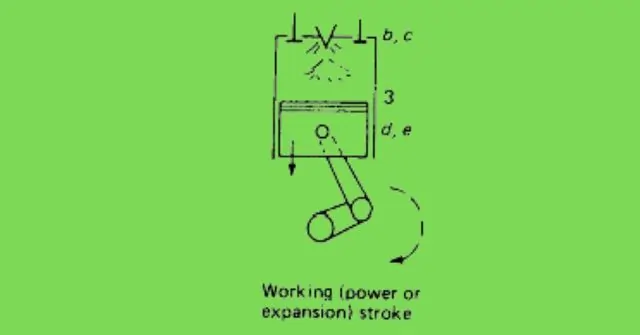

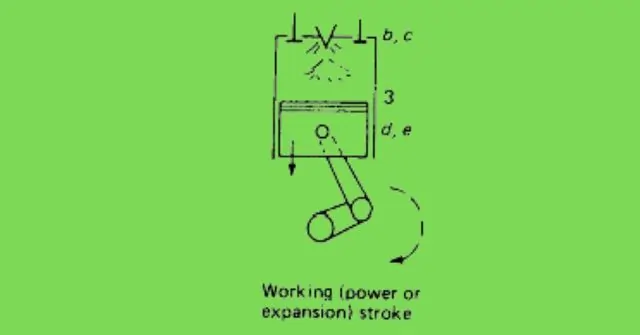

Phase 3: Power Up – Power Stroke

Just before the end compression stroke, fuel is injected inside the cylinder. This fuel gets ignited due to the heat developed in the compression stroke. Cylinder pressure rises during the spread of combustion and forces the piston downward in the Power stroke.

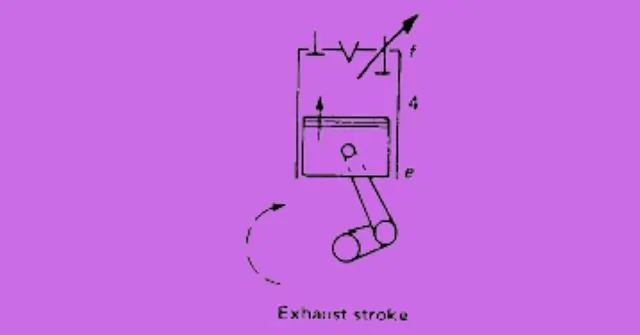

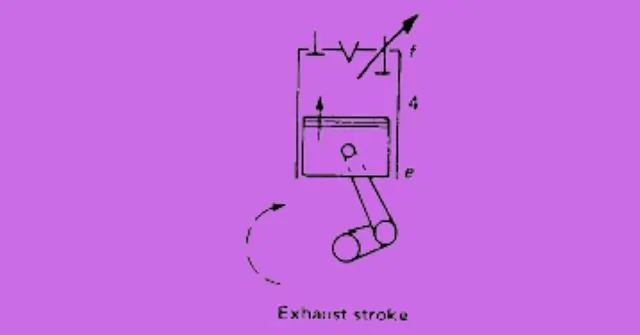

Phase 4: Breathe Out – Exhaust Stroke

The piston moves upward in this stroke pushing the burnt gases through the open exhaust valve.

At the end exhaust valve closes and before the closing of the exhaust valve inlet valve opens. The four-stroke cycle begins again in repetition.

Precise Fuel Injection

Imagine engines as hungry machines that need fuel to run. In advanced diesel engines, there’s a clever trick called “precise fuel injection.” It’s like giving the engine exactly the right amount of fuel it craves, just when it needs it. Think of it as measuring ingredients for a recipe – too much or too little won’t taste right. This accuracy matters because it helps engines get the most power possible from the fuel they use.

By injecting fuel at the perfect moment and in the perfect amount, engines become stronger, use less fuel, and pollute the air less. It’s like teaching an engine a secret formula to perform its best. This smart technology is a big reason why today’s engines are more powerful, use less fuel, and are nicer to our Earth.

Comparing Four-Stroke Diesel Engines and Two-Stroke Engines

| Sr. No. | Four Stroke Engine | Two Stroke Engine |

| 1 | One cycle completed in two revolutions of the Crankshaft | One cycle completes in each rotation of the crankshaft |

| 2 | There is one power stroke in every four strokes of the piston | Power stoke in two-stroke of piston |

| 3 | Due to the valves and valve operating mechanism engine design is complicated | The design of A stroke engine is simple due to the nonrequirement of valves and valve mechanisms. |

| 4 | Fuel doesn’t need the addition of lubrication. | The addition of lubrication is required in two-stroke engines |

| 5 | The piston top is simple and flat | A Bump/ pro-turbulence is the requirement of a piston top. |

| 6 | The fuel mixture is limited to the combustion chamber. | Air fuel mixture routes through the combustion chamber. |

| 7 | Four-stroke engines are heavy | Two-stroke engines are lighter comparatively. |

| 8 | Noise level is low in four-stroke engines | Two-stroke engines are noisy |

Four-Stroke Diesel Engines advantages

Listing below the advantages of four strokes Engine

- Torque made by four-stroke engines at low RPM is more than two-stroke engines.

- The fuel efficiency of four-stroke engines is higher than that of two-stroke engines since fuel is consumed once in four strokes.

- Four-stroke engines produce less pollution.

- Ife of four-stroke engines is more than the two-stroke engines due to the engine RPM.

- There is no extra requirement for lubricating oil in four-stroke engines other than the lubrication of moving parts.

Four-Stroke Diesel Engines disadvantages

- Due to the valves and valves operating mechanism, the design of four-stroke engines is complicated. It becomes difficult to carry out the troubleshooting due to the more parts.

- Four-stroke design engines are less powerful than the two-stroke engines since there is one power stroke and four strokes.

- Maintenance cost is expensive in four-stroke engines due to the involvement of more parts

Wrapping Up the Insights

In a world where oceans touch the sky, special marine engines called four-stroke diesels play a big role. They’re great at turning fuel into movement and they’re tough too. These engines are like loyal partners for sea journeys. Learning about them shows how we’ve cleverly made things move on water and gives credit to our smart engineering.

FAQ on ” Four Stroke Diesel Engine Working”

Q: How does a four-stroke diesel engine work?

A: It operates through four phases: intake, compression, power, and exhaust.

Q: What’s the purpose of the compression stroke?

A: It squeezes the air to ignite the diesel fuel without spark plugs.

Q: Why are diesel engines more efficient?

A: They extract more energy from fuel due to high compression ratios.

Q: Are four-stroke diesel engines durable?

A: Yes, their robust construction makes them long-lasting and reliable.