Auto Transformers

Auto transformers are a crucial component in modern electrical engineering, known for their unique design and efficiency. Unlike conventional transformers, auto transformers share a single winding, allowing for a more compact and cost-effective solution. Understanding their design, function, and various applications is essential for leveraging their full potential in electrical circuits, power distribution, and voltage regulation. This knowledge helps engineers optimize performance, reduce costs, and enhance system reliability.

In this blog post, we will explore the five ultimate benefits of auto transformers for modern tech: enhanced efficiency, cost-effectiveness, versatility in applications, improved power quality, and significant space and weight reduction. By delving into these key advantages, we aim to highlight why auto transformers are becoming increasingly indispensable in today’s technological landscape.

What Are Auto Transformers?

Definition and Basic Explanation

Auto transformers are a type of electrical transformer characterized by having a single winding that serves both as the primary and secondary winding. This design differentiates them from conventional transformers, which use separate windings for the primary and secondary circuits. The auto transformer operates by tapping into various points along the winding to provide different voltage levels, making it a versatile and cost-effective solution for many electrical applications.

Working of the Auto Transformer

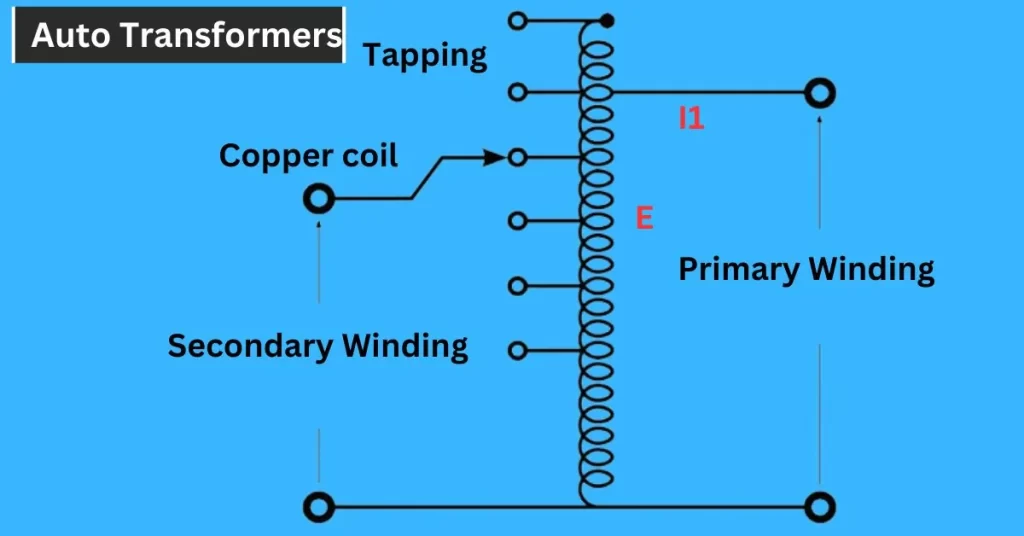

An auto transformer is a type of electrical transformer with a single winding that acts as both the primary and secondary winding. It includes taps at various points to provide different voltage levels. Here’s an explanation of its working, incorporating the components and required formulas.

Components

- Primary Winding (Input)

- Secondary Winding (Output)

- E (Electromotive Force or Voltage)

- I1 (Primary Current)

- Tapping

- Copper Coil

Working Principle

The auto transformer operates on the principle of electromagnetic induction. When an alternating current (AC) flows through the primary winding, it creates a magnetic field. This magnetic field induces a voltage in the secondary winding.

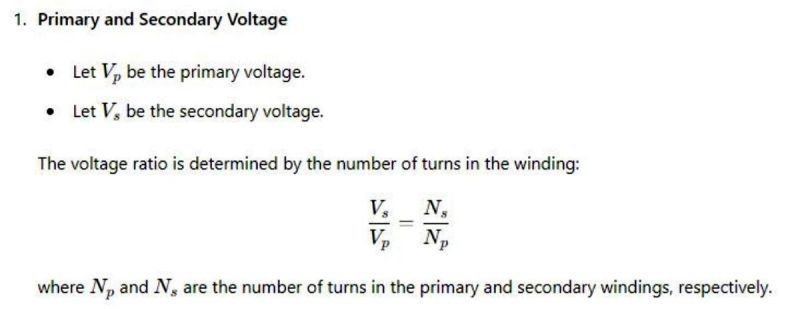

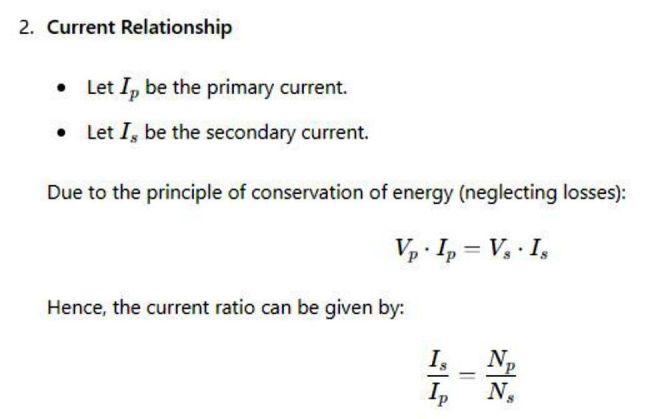

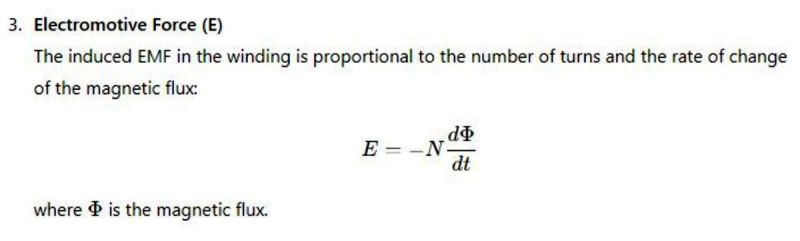

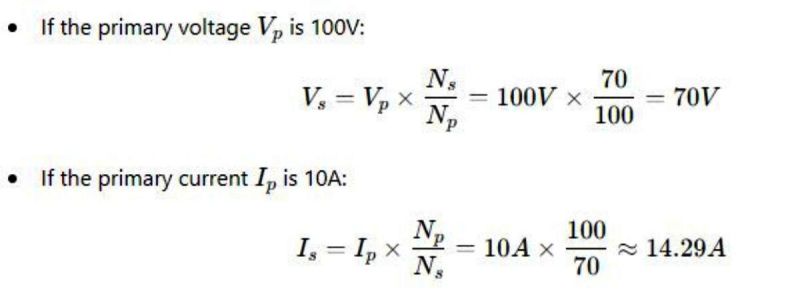

Formulas and Explanation

4. Tapping Tapping points on the winding allow for different voltage outputs. By connecting to different taps, you can obtain different secondary voltages.

Example

Consider an auto transformer with a total of 100 turns. If the tapping is at 70 turns, the primary winding is connected across the entire 100 turns, and the secondary winding is across 70 turns.

Comparison with Conventional Transformers

| Comparison | Auto Transformer | Conventional Transformer |

|---|---|---|

| Design | Uses a single winding for both primary and secondary circuits. | Utilizes separate windings for the primary and secondary circuits. |

| Efficiency | Generally more efficient due to reduced copper losses and better utilization of the winding. | Slightly less efficient because of the additional losses in the separate windings. |

| Cost | More cost-effective as it requires less copper and iron, leading to lower manufacturing costs. | More expensive due to the need for separate windings and increased material usage. |

| Size and Weight | Typically smaller and lighter, making it suitable for applications where space and weight are constraints. | Larger and heavier due to the dual winding structure. |

| Applications | Used in voltage regulation, power distribution, and scenarios requiring variable voltage levels. | Widely used in isolation, impedance matching, and scenarios requiring strict separation between primary and secondary circuits. |

5 Ultimate Benefits For Modern Tech

Benefit 1: Enhanced Efficiency

Detailed Comparison of Efficiency Between Auto Transformers and Conventional Transformers

| Aspect | Auto Transformer | Conventional Transformer |

|---|---|---|

| Design | Uses a single winding for both primary and secondary circuits, resulting in reduced copper losses. | Utilizes separate windings for primary and secondary circuits, leading to additional losses in the separate windings. |

| Copper Losses | Lower copper losses due to the shared winding. | Higher copper losses due to the use of two separate windings. |

| Core Utilization | Better utilization of the core, as the single winding interacts more efficiently with the core material. | Less efficient core utilization because of the separate primary and secondary windings. |

| Overall Efficiency | Generally higher overall efficiency due to fewer losses and better core utilization. | Slightly lower overall efficiency because of additional losses and less optimal core interaction. |

Examples of Scenarios Where Auto Transformers Provide Superior Efficiency

- Voltage Regulation in Industrial Settings

- Auto transformers are often used in industrial settings where precise voltage regulation is required. Their higher efficiency means less energy is wasted in the transformation process, leading to lower operational costs and improved energy management.

- Power Distribution in Large Buildings

- In large commercial buildings, auto transformers can efficiently manage the distribution of power across different floors and sections. Their ability to adjust voltage levels with minimal losses ensures reliable power delivery and reduces the overall energy consumption of the building.

- Renewable Energy Systems

- Auto transformers are used in renewable energy systems, such as wind and solar power installations, to efficiently convert and distribute the generated power. Their enhanced efficiency helps maximize the output from these systems and ensures more sustainable energy usage.

Real-World Applications Showcasing Efficiency Improvements

- Electric Vehicle Charging Stations

- Auto transformers are utilized in electric vehicle (EV) charging stations to manage the voltage levels required for charging. Their high efficiency ensures that more of the input power is converted into useful charging power, reducing energy losses and speeding up the charging process.

- HVAC Systems in Modern Buildings

- Heating, ventilation, and air conditioning (HVAC) systems in modern buildings often use auto transformers for voltage regulation. The efficiency of auto transformers helps reduce the energy consumption of HVAC systems, leading to lower utility bills and a smaller carbon footprint.

- Power Supply Systems in Data Centers

- Data centers require reliable and efficient power supply systems to maintain continuous operation. Auto transformers are used to regulate the voltage levels in these systems, ensuring high efficiency and minimizing power losses, which is critical for maintaining the uptime and performance of data centers.

Benefit 2: Cost-Effectiveness

Analysis of Cost Savings in Terms of Materials and Energy Consumption

| Aspect | Auto Transformer | Conventional Transformer |

|---|---|---|

| Material Usage | Uses less copper and iron due to a single winding design, resulting in lower material costs. | Requires more copper and iron for separate windings, leading to higher material costs. |

| Manufacturing Costs | Simplified design reduces manufacturing complexity and cost. | More complex manufacturing process increases costs. |

| Energy Consumption | Higher efficiency leads to reduced energy losses and lower operational costs. | Lower efficiency results in higher energy losses and increased operational costs. |

| Maintenance Costs | Fewer components and simpler design lead to lower maintenance costs. | More components and complex design can lead to higher maintenance costs. |

Long-Term Financial Benefits for Industries Using Auto Transformers

- Reduced Initial Investment

- The lower material and manufacturing costs of auto transformers result in a reduced initial investment compared to conventional transformers. This makes them an attractive option for industries looking to optimize their capital expenditure.

- Lower Operational Costs

- The high efficiency of auto transformers translates to lower energy consumption, reducing operational costs over time. Industries benefit from lower electricity bills and improved energy management.

- Decreased Maintenance Expenses

- The simplified design of auto transformers, with fewer components and lower complexity, leads to reduced maintenance requirements and costs. This ensures long-term financial savings for industries.

Case Studies Highlighting Cost-Effectiveness in Various Applications

| Application | Case Study | Cost-Effectiveness |

|---|---|---|

| Manufacturing Plants | A manufacturing plant replaced conventional transformers with auto transformers in their power distribution system. | The plant reported a 20% reduction in energy costs and a 15% decrease in maintenance expenses over 5 years. |

| Commercial Buildings | A commercial building integrated auto transformers for voltage regulation across multiple floors. | The building saw a 25% reduction in initial investment costs and a 30% decrease in annual electricity bills. |

| Renewable Energy Installations | A solar farm implemented auto transformers to manage power conversion and distribution. | The installation experienced a 10% increase in energy efficiency and significant savings in material costs. |

Benefit 3: Versatility in Applications

Exploration of Different Applications in Electrical Circuits and Systems

| Application Area | Auto Transformer Uses |

|---|---|

| Voltage Regulation | Used to maintain stable voltage levels in electrical circuits, ensuring consistent performance. |

| Power Distribution | Efficiently distributes power across different sections of a network, adapting to various voltage needs. |

| Industrial Equipment | Powers heavy machinery and equipment by providing the required voltage levels with minimal losses. |

| Renewable Energy Systems | Converts and regulates voltage levels in solar and wind power installations. |

| Residential Use | Used in appliances and home electrical systems to regulate and convert voltages. |

Flexibility in Voltage Regulation and Power Distribution

| Aspect | Auto Transformer |

|---|---|

| Voltage Regulation | Provides precise voltage control through various tapping points, ensuring optimal performance in diverse applications. |

| Power Distribution | Adapts to different voltage requirements efficiently, making it suitable for complex power distribution networks. |

| Load Adaptability | Can handle varying loads and adjust voltage levels accordingly, enhancing system reliability and efficiency. |

Examples of Industries and Technologies Benefiting from Their Versatility

| Industry/Technology | Benefits of Auto Transformers |

|---|---|

| Manufacturing | Ensures consistent voltage for machinery, improving operational efficiency and reducing downtime. |

| Telecommunications | Regulates power supply to telecom equipment, ensuring stable operation and reliable communication services. |

| Electric Vehicles (EVs) | Manages power conversion and distribution in EV charging stations, enhancing charging efficiency and reducing energy losses. |

| Renewable Energy | Facilitates efficient power conversion and distribution in solar panels and wind turbines, maximizing energy output and system reliability. |

| Data Centers | Provides stable voltage to sensitive IT equipment, ensuring uninterrupted operation and protecting against power fluctuations. |

Benefit 4: Improved Power Quality

Explanation of How Auto Transformers Enhance Power Quality

| Aspect | Description |

|---|---|

| Voltage Stability | Auto transformers provide stable and consistent voltage output, reducing fluctuations and ensuring high-quality power supply. |

| Harmonic Reduction | By maintaining a stable voltage, auto transformers help minimize harmonics and electrical noise in the power system. |

| Reactive Power Control | Efficiently manage reactive power, improving the power factor and reducing the burden on the electrical grid. |

Reduction of Losses and Voltage Drops

| Aspect | Auto Transformer Benefits |

|---|---|

| Copper Losses | Reduced due to a single winding design, leading to lower energy losses and increased efficiency. |

| Voltage Drops | Lower voltage drops across the winding, ensuring consistent voltage levels at the output. |

| Energy Efficiency | Higher overall energy efficiency due to reduced losses, leading to cost savings and improved power quality. |

Impact on Overall System Stability and Reliability

| Aspect | Auto Transformer Contribution |

|---|---|

| System Stability | Enhances system stability by providing a reliable and stable voltage output, even under varying load conditions. |

| Reliability | Increases the reliability of electrical systems by reducing the risk of voltage sags, swells, and interruptions. |

| Protection | Helps protect sensitive equipment from power quality issues, extending their lifespan and reducing maintenance costs. |

Benefit 5: Space and Weight Reduction

Comparison of Size and Weight with Conventional Transformers

| Aspect | Auto Transformer | Conventional Transformer |

|---|---|---|

| Size | Typically smaller due to the single winding design. | Larger due to separate primary and secondary windings. |

| Weight | Lighter because of reduced material usage (less copper and iron). | Heavier due to the need for more materials to construct separate windings. |

| Core Design | More compact core design, contributing to overall size and weight reduction. | Bulkier core design needed to support separate windings. |

Importance of Compact Design in Modern Tech Applications

| Application Area | Importance of Compact Design |

|---|---|

| Consumer Electronics | Compact design allows integration into smaller devices, enhancing portability and user convenience. |

| Medical Equipment | Smaller transformers are easier to integrate into medical devices, making them more portable and versatile for various uses. |

| Renewable Energy | Space-saving design is crucial for installations like solar panels and wind turbines where space is limited. |

Benefits for Mobile and Space-Constrained Applications

| Application Area | Benefits of Auto Transformers |

|---|---|

| Electric Vehicles (EVs) | Lighter and smaller transformers reduce the overall weight of the vehicle, improving energy efficiency and performance. |

| Aerospace | Reduced weight is critical for aircraft and spacecraft, contributing to better fuel efficiency and payload capacity. |

| Portable Power Units | Compact transformers enable the design of portable power units, making them easier to transport and deploy in remote areas. |

| Telecommunication Towers | Smaller size allows for easier integration into telecom infrastructure, optimizing space and improving aesthetics. |

FAQ on “Auto Transformers”

Q: What is an auto transformer?

A: An auto transformer uses a single winding for both primary and secondary functions.

Q: How do auto transformers improve efficiency?

A: They reduce copper losses and better utilize the core material.

Q: Why are auto transformers cost-effective?

A: They require less copper and iron, reducing costs.

Q: Where are auto transformers commonly used?

A: They are used in voltage regulation and power distribution.

Conclusion

Auto transformers stand out as a versatile and efficient solution in modern electrical engineering, offering five ultimate benefits: enhanced efficiency, cost-effectiveness, versatility in applications, improved power quality, and significant space and weight reduction. These benefits make them indispensable in various industries, from manufacturing and renewable energy to telecommunications and aerospace.

By providing superior efficiency and reducing operational costs, auto transformers not only improve energy management but also deliver long-term financial savings. Their adaptability in voltage regulation and power distribution enhances system reliability and stability, ensuring consistent performance across diverse applications. Moreover, the compact and lightweight design of auto transformers makes them ideal for mobile and space-constrained environments, further underlining their relevance in today’s technology-driven world.

As we continue to advance technologically, the importance of optimizing electrical systems cannot be overstated. Auto transformers present an excellent opportunity to achieve these optimizations, making them a valuable consideration for any application requiring reliable and efficient power management. We encourage you to explore the potential of auto transformers in your projects and take advantage of the numerous benefits they offer.