Table of Contents

Engine Room Machinery

Any marine engineer who works on ships knows there is a world of difference between the theoretical knowledge you can learn in a ship’s book and the practical skills you learn by getting your hands dirty in the engine room. There is no substitute for the knowledge gained through years of experience in the engine room, but no marine engineer survived, ignoring book knowledge.

Ship engine rooms are equipped with different engine systems, each requiring a specific approach to performing maintenance and troubleshooting. Only through a healthy combination of knowledge and practical skills can marine engineers understand their machines from the inside out

10 Key Points Every Marine Engineer Must Know

Starting and Stopping Machinery: A Must-Know Skill for Marine Engineers

All ships are different and have different engine systems. The primary type of engine system is the same for all but operating and maintenance procedures vary by the engine manufacturer and vessel type. It is imperative for Marine engineers to fully understand how their machines start and stop before doing any other work. Starting and stopping procedures can be learned by using the operating instructions for the individual mechanical system and asking a colleague/senior in the machine room. Many times Engineers are scared to share doubts with seniors. Junior Engineers feel that they will be exposed to their poor knowledge.

This thinking bars them from getting exposure to their understanding. But this is not the case. Most seniors are helpful and ready to teach and impart their knowledge and share the same with their subordinates, provided they have the proper approach to asking the doubts. It’s always better to know everything about your machine in advance than regret carrying it around in case of a breakdown or emergency.

Thoroughly Reading the Machinery Manual: Essential Advice

As a marine engineer, it is essential to have a good understanding of the machinery manual. You should not just read and understand the manual but also have a good memory. Without this knowledge, it is impossible to comprehend the functioning of different machinery parts and how they must be used and maintained. Marine engineers really need to know engine manuals well.

It helps them understand everything about their job, from how parts work to keeping them in good shape This will also help them find possible issues before they turn into big problems needing expensive fixes or replacements By reading and memorizing their machinery manual, marine engineers can ensure that their equipment runs as smoothly as possible for years to come.

The Ultimate Guide: Machinery Records

Ship engineers should carefully research the history of each engine room machine. Marine engineers can plan routine maintenance procedures and swiftly create troubleshooting measures thanks to these records. With this knowledge, you may choose more wisely how to resolve and stop these problems from happening. Additionally, you can contrast the equipment to observe which ones are operating more effectively than others. Making more educated selections regarding which machines to utilize for particular activities may be aided by records of a machine.

Exploring Key Details of Critical Maintenance Tasks

Running machines well and avoiding breakdowns means understanding past maintenance details. Old reports show engineers what problems happened before, what else was connected, and how they fixed them. Marine engineers study these to know what issues happened before and how a machine acts in different situations.

Grasping this data helps engineers spot possible problems early and fix them before they become bigger or costlier.. They can identify patterns for particular machines by reviewing older reports, which enables them to predict issues before they arise.

It is recommended to track machine uptime

Recording the hours a ship runs is crucial for its overall health in the long run. It helps the engineer to plan and perform the following maintenance procedure depending on the running hours of the machinery. Keeping track of running hours gives an idea about when the parts need to be replaced or serviced so they can keep functioning properly.

A system that keeps track of hours can make this easier and quicker. Engineers will be alerted by this system if equipment is likely to fail soon so they can take preventative measures.

Knowing the running parts Clearances

One of the essential aspects of the engine room machinery is to be aware of the different types of clearances. Clearance is necessary to ensure that all parts of the machine move correctly and that no part touches or interferes with other parts. These clearances can be even more critical on ships as they can cause catastrophic damage if not done correctly. Marine engineers must carefully monitor the clearances of various parts of the machinery, such as bearing and bumping clearances in compressors, crank pin and piston ring clearances in generators, etc., as they are an essential part of any planned maintenance system. These data would help to plan out and schedule the next maintenance operation.

Examine Past Records for Part Changes

Marine engine systems are constantly subjected to routine maintenance procedures, often involving significant repairs. Some mechanical parts must be changed during such procedures to carry out repair work. For example, extensive repair (by grinding) of a crankshaft journal in a marine engine will also change the dimensions of adjacent components, such as shell bearings. Therefore, engineers need to review historical records to see if changes have been made to mechanical parts and to ensure that future maintenance or repair work uses the correct replacement parts.

Know what spare parts you need

The basic spare parts needed for machinery must be understood by marine engineers. The ship runs safely and efficiently when the required parts are obtained and installed properly.

Marine engineers need to be familiar with the many spare components, their functions, and where to find them. By knowing the available replacement parts, when to replace them, and where to find them, marine engineers can maintain their ships in top shape.

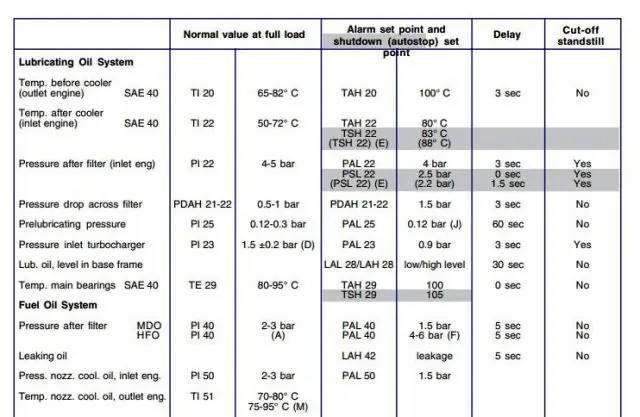

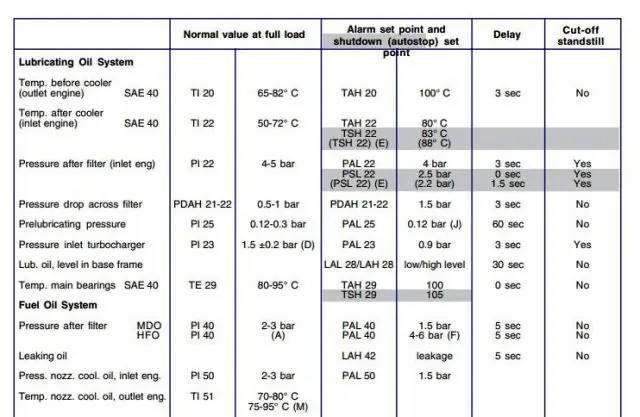

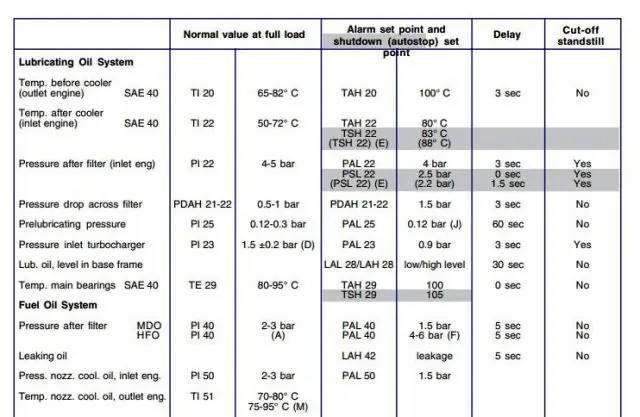

Important Tests for Water and Lubricants

All the important machines and equipment in the engine room need to undergo various tests to make sure they work properly. As a marine engineer, you must know about these tests, how to do them, and the steps to take samples.

Accurate tests are very important for checking water and lubricants. Engineers need to test boiler water, generator lube oil, cooling systems, and more. These tests help them understand what’s in these substances and what chemicals they contain. Knowing these tests helps engineers find problems that might come from bad water or lubricant quality. Doing these tests makes sure the right quality is used for each job, making things work better and stopping things from breaking down too much.

Check logbook parameters for the last 3 months

The logbook is one of the onboard references that marine engineers must refer to daily. Apart from that, you should take the time to examine the machine’s logbook parameters, especially over the last three months, to understand any common problems or significant changes that have occurred in regular operations. If an engineer is new to ships, the logbook is the best and quickest reference to help him know and understand his engine systems.

By regularly checking logbook parameters for the past three months, marine engineers can quickly spot any changes in the performance or efficiency levels of the engine. Regular checking of log books allows them to take proactive measures if needed, such as replacing specific components or adjusting existing settings. Regular maintenance of logbook parameters also helps reduce repair costs and keep vessels running smoothly,

FAQ on ” Engine Room Machinery

Q: Why is it important for marine engineers to understand maintenance?

A: Knowing maintenance prevents breakdowns and keeps operations running smoothly.

Q: How does knowing about spare parts help marine engineers?

A: Understanding spare parts types, functions, and sources improves repair efficiency.

Q: Why are tests necessary for engine room machinery?

A: Tests make sure equipment works well and reveal possible problems.

Q: Why should marine engineers know about machine history?

A: Machine history predicts issues, guides maintenance planning, and maintains efficiency.

Blog Post Conclusion

We hope you enjoyed our article about Marine Engineer should know: 10 points of engine room machinery. This was a great article to help those who are just starting out in the marine engineering world and to familiarize the readers with the basics. If you have any questions, Thank you for reading, we would love to hear from you!