Diesel Generator Basic Knowledge

“Welcome to our guide on the Best Knowledge On DG Sets. A DG or Diesel Generator Set is like a backup power hero. It’s there to save the day when the electricity goes out. The knowledge will rescue you in all emergencies.

We will explain step by step and will explain the importance of each step. Whether you’re a seasoned DG Set owner or just starting, we’ve got something for everyone.

Our guide will cover the basics of advanced techniques. You’ll learn to store your DG Set properly, keep it rust-free, and ensure it’s always ready to kick into action when needed.

So, keep reading if you want to be the hero in your power outage story and keep your DG Set in the best shape possible. Let’s dive into the Best Knowledge On DG Sets together!”

Short Description of DG sets

Diesel Generator Components

A DG set comprises important parts that must work together to function properly. These important parts are:

Prime Mover (Diesel Engine) and Associated Accessories: The heart of the DG set is the prime mover, typically a diesel engine, which provides the necessary mechanical energy to generate electricity.

Alternator (AC Generator): The alternator, also known as an AC generator, converts the mechanical energy from the prime mover into electrical energy.

Switchgear and Control System: Switchgear and control systems are essential for managing the flow of electricity, ensuring the safety of the DG set, and allowing for its smooth operation. Switches, control panels, and circuit breakers are some of them.

Powerhouse Design and Foundation Civil Work: The design of the powerhouse and the civil work for the foundation are critical aspects of DG set installation. Proper design and construction ensure the stability and durability of the generator’s installation.

Connected Load on Self-Components: The DG set’s performance is influenced by the connected load, which includes various electrical devices such as heaters, motor drives, lighting systems, and more. Knowing how much electrical power it needs to provide is important to ensure a DG set works well.

In short, for a DG set to work properly, all its parts must work together smoothly.

How Voltage is Produced and Maintained in a Generator

Generators are essential for converting mechanical energy into electrical energy, and understanding how voltage is produced and maintained is key to ensuring reliable performance. Here’s an overview of how this process works:

1. Voltage Production in a Generator

- Electromagnetic Induction: Voltage is produced in a generator through the principle of electromagnetic induction. When the generator’s rotor, which is connected to a prime mover (like an engine or turbine), rotates, it causes a magnetic field to move across the stator windings.

- Stator and Rotor Interaction: The rotor has a magnetic field, either from permanent magnets or an electromagnet, and as it spins inside the stator (a coil of wire), it induces an electromotive force (EMF) in the stator windings. This EMF is the voltage generated.

- Prime Mover’s Role: The rotation speed of the prime mover directly affects the voltage level. Higher rotational speed induces a higher voltage, while lower speed decreases it.

2. Maintaining Voltage in a Generator

- Automatic Voltage Regulator (AVR): The key to maintaining a stable voltage output is the Automatic Voltage Regulator (AVR). The AVR continuously monitors the generator’s output voltage and adjusts the excitation to the rotor field. When the voltage fluctuates due to load changes, the AVR increases or decreases the excitation current to stabilize the voltage.

- Excitation System: The excitation system provides the necessary field current to the rotor. By controlling this current, the AVR adjusts the generator’s output voltage. If the load increases, more excitation is supplied to maintain the voltage level, and vice versa.

- Load Regulation: As electrical loads connected to the generator change, the generator’s internal controls and AVR maintain a consistent output voltage. Load regulation ensures that the generator can handle varying demands without significant voltage fluctuations.

- Prime Mover Speed Control: In addition to the AVR, the speed of the prime mover must be controlled accurately. Any significant variations in the speed can cause voltage to deviate, so the governor system regulates the speed to ensure the voltage remains stable.

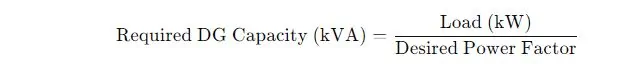

Estimating DG Set Rating: Formulas

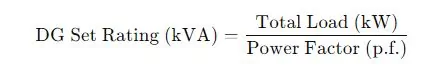

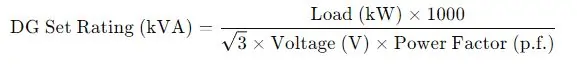

1. DG Set Rating in kVA

To estimate the DG set rating in kVA, you can use the

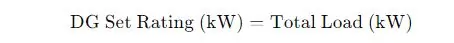

2. DG Set Rating in kW

To find the DG set rating directly in kW,

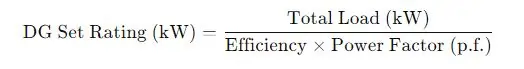

3. DG Set Rating Considering Efficiency

Sometimes you need to consider the efficiency of the DG set:

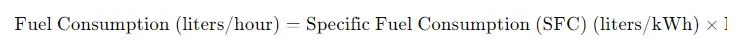

4. Fuel Consumption Estimation

Fuel consumption can also be an important factor

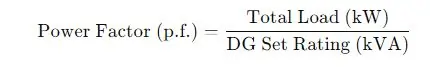

5. Power Factor Calculation

If you know the kVA rating but need to estimate the power factor, use

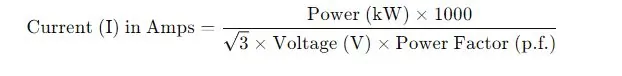

6. Amperage Calculation

For sizing cables or other electrical components, you might need to calculate the current

7. DG Set Rating for Three-Phase Load

If dealing with a three-phase load

Types of Cooling in DG sets

There are two primary types of cooling systems used in DG sets:

- Air Cooling: This method uses air circulation to dissipate heat and maintain proper engine temperatures.

- Water Cooling: Water-cooled DG sets are considered superior to air-cooled ones. In hot summer conditions, air cooling may struggle to keep the engine’s cooling water temperatures within acceptable limits, while water cooling is more effective in such scenarios.

Why Small DG Sets Shouldn’t Be Paralleled with the Grid Supply

Small DG sets should not be paralleled with the grid supply for several reasons. When connected to the grid, a small DG set faces risks related to safety and protection mechanisms.

- Reverse Power Relay: Grids operate as infinite buses with a constant power supply. Small DG sets may not provide sufficient power output to match the grid’s supply. Paralleling them could lead to reverse power flow, triggering reverse power relays. These relays are designed to prevent power from flowing back into the DG set, safeguarding its operation.

- Voltage and Frequency Relay: Grids maintain stable voltage and frequency levels. Small DG sets, especially if not synchronized precisely, may struggle to match these levels. Paralleling can result in voltage and frequency deviations, which can be detrimental to the DG set’s performance and reliability.

In summary, small DG sets are not ideal for paralleling with the grid supply due to the risk of encountering reverse power relay issues and potential voltage and frequency discrepancies. Proper synchronization and sizing considerations are crucial when integrating DG sets with the grid to ensure safe and efficient operation.

Unbalanced loads and its effect on DG set operation

1. Unbalanced Load Calculation

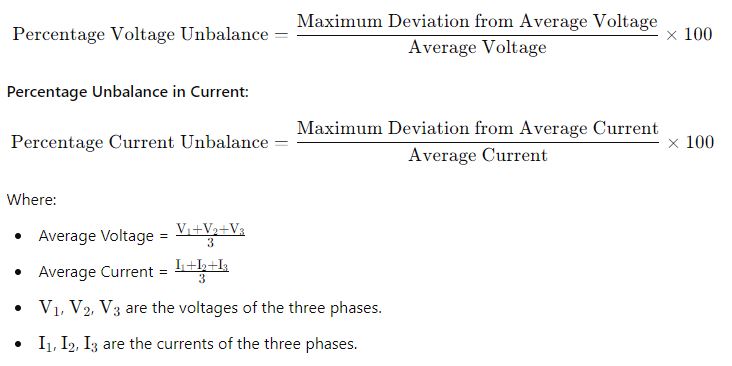

For a three-phase system, an unbalanced load means that the current in each phase is different. To calculate the degree of unbalance, you can use the following formulas:

Percentage Unbalance in Voltage:

2. Effect of Unbalanced Loads on DG Set Operation

1. Neutral Shifting and Voltage Imbalance

Unbalanced loads cause the neutral point to shift, which can result in a voltage imbalance. The effect can be calculated by considering the voltage difference between phases:

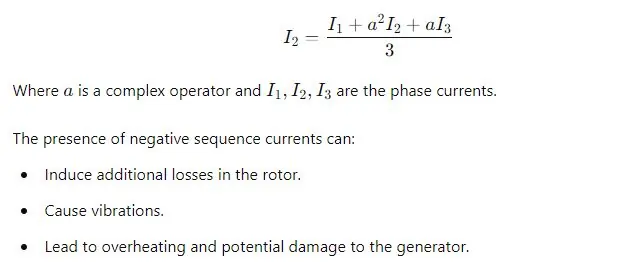

2. Negative Sequence Currents

Unbalanced loads produce negative sequence currents that rotate in the opposite direction to the generator’s rotor. The formula for negative sequence current I2 is:

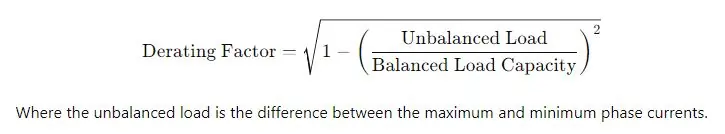

**3. Derating the DG Set

Because of the unbalanced load, the DG set may need to be derated. The derating factor can be estimated as:

3. Mitigating the Effects of Unbalanced Loads

To mitigate the effects of unbalanced loads:

Monitoring and Alarms: Implement real-time monitoring of phase currents and voltages to detect and address unbalances promptly.

Load Management: Ensure that loads are evenly distributed across the phases.

Phase Balancers: Use devices that automatically balance the load.

Effects of running DG set at a low power factor

Running a Diesel Generator (DG) set at a low power factor has several adverse effects on the generator’s performance, efficiency, and operational costs. Understanding these effects can help in optimizing the use of the DG set and avoiding unnecessary wear and tear.

1. Increased Apparent Power Demand

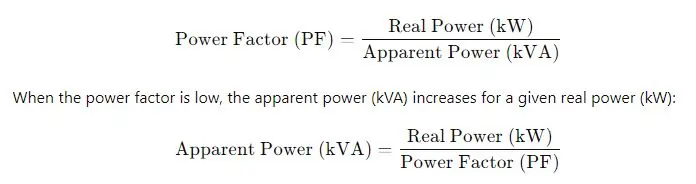

The power factor (PF) is the ratio of real power (kW) to apparent power (kVA). A low power factor means more apparent power is required to deliver the same amount of real power. The relationship is given by:

This increase in apparent power demand can lead to the following issues:

- Overloading the DG Set: The generator must handle more current, which can cause overheating and possible damage to the windings and insulation.

- Increased Fuel Consumption: As the DG set works harder to produce the required power, fuel consumption rises, leading to higher operating costs.

2. Reduced Efficiency

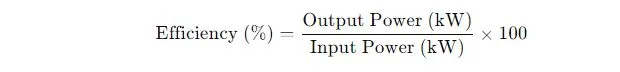

The efficiency of the DG set decreases with a lower power factor. Efficiency can be expressed as:

A low power factor causes the DG set to draw more input power for the same output, reducing overall efficiency. This results in:

- Higher Operational Costs: More fuel is burned for the same amount of usable power, increasing operational costs.

- Reduced Lifespan: Continuous operation at a low power factor can reduce the lifespan of the generator due to the additional stress on components.

3. Increased Heat Generation

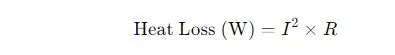

A low power factor causes more current to flow through the generator, leading to higher resistive losses (I²R losses) in the windings:

Where III is the current and RRR is the resistance. With more current due to a low power factor, heat generation increases, which can cause:

- Overheating: Leading to insulation failure, reduced efficiency, and potential shutdowns to prevent damage.

- Higher Maintenance Costs: More frequent maintenance may be required to deal with the effects of overheating.

4. Voltage Regulation Issues

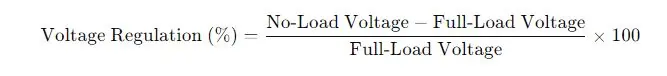

Low power factor can adversely affect the voltage regulation of the DG set. Voltage regulation is the ability of the generator to maintain a constant output voltage as the load varies:

A low power factor can cause:

- Poor Voltage Regulation: Fluctuations in voltage, which can affect the performance of connected equipment.

- Increased Stress on AVR (Automatic Voltage Regulator): The AVR may struggle to maintain stable voltage, leading to additional wear and possible failure.

5. Need for Larger Capacity DG Sets

To compensate for the effects of a low power factor, larger capacity DG sets may be required to handle the same load:

This leads to:

Inefficient Utilization: Operating a larger DG set at less than its full capacity can be inefficient and uneconomical.

Higher Initial Costs: Larger DG sets are more expensive to purchase and install.

Factor affecting waste heat recovery from flue gases

- Loading of DG set

- Exhaust gas temperature after the Turbocharger

- Operating hours

- Back pressure on DG set

Impact of Back pressure in the exhaust gas system

Additional pressure drop in the waste heat recovery unit causes back pressure in flue gas pathways. The back pressure should be between 250 to 300 mm of Wc.

Waste heat recovery methods from DG set flue gases

- Waste heat recovery Boiler ( WHRB)

- Hot water use in the vapor absorption system

Application of Waste heat recovery system of DG set

- Steam generation by WHRB

- Pre-heating of combustion air for heaters and furnaces.

- Air heating in dryers

- Process hot water generation

- Process thermal oil heating

- Use in vapor absorption refrigeration system

- Pre-heating of Stock furnaces

Special Instruments to carry out the energy audit of the DG set.

- Fyrite kit for the measurement of CO2 % in flue gases

- Optic Pyrometer with sensor

- Anemometer with vane for measuring the radiator air velocity

- Engine Speed measuring digital tachometer

- Load manager/ Power Analyser to measure the electrical parameters ( Voltage, current, KW, KVA, and Power factor)

Energy conservation methods for DG set

- Waste heat recovery from flue gases

- Load factor improvement

- Installation of a paralleling system for the improved loading and economical operation of DG sets

- Filtration improvement

DG set performance analyzing parameters.

- Average Engine loading

- Average Alternator loading

- Alternator loading percentage

- Engine loading percentage

- Specific power generation KWH/ litre.

Vital steps during the selection of DG set with non-linear loads

Application check for the following loads.

- Rectifier/ Thyristor loads

- Welding loads

- Furnace Loads

Take the consultation from the OEM of DG set for the proper recommendations on achievement of desired utilization of DG set without any problem.

Identify the loads sensitive to voltage, frequency regulation, and voltage waveform, and feed such loads by a dedicated power supply which usually assumes the form of a DG motor-driven generator set. This alternative will ensure the restriction of the design of the AC generator. This process will also restrict the overall cost of the DG set.

Consider the following points while selecting the engine for the Dg set.

- Engine Power

- Engine Speed.

Engine Power;- Maximum load is the decisive factor for the power requirement. Engine power rating should be 10 to 20% more than the power requirement demanded by the end-user. By choosing the extra rating will prevent the engine from getting overload.

Engine Speed’- Engine speed is the other important factor for the selection of an Engine. The engine will be more efficient at optimum speed. Operate The DG set at the rated speed to avoid unwanted deposits in the combustion chamber and exhaust manifold.

Diesel Power plant advantages

Diesel power plants are widely used for power generation due to their numerous advantages, making them an essential component in both industrial and residential applications. Below is a detailed description of the key benefits of diesel power plants:

1. Low Installation Cost

One of the most significant advantages of diesel power plants is the relatively low installation cost. Compared to other power generation systems, diesel power plants require fewer components and simpler infrastructure, reducing the capital investment required. This makes diesel power plants an attractive option for small to medium-sized power generation needs, especially in remote areas where the cost of installation is a critical factor.

2. Short Delivery Periods

Diesel power plants have short delivery periods, which means they can be installed and made operational in a relatively short amount of time. This is particularly advantageous in situations where power is urgently needed, such as in emergency power situations or when a rapid expansion of capacity is required. The quick setup time makes diesel power plants an ideal choice for temporary power solutions and areas with rapidly growing power demands.

3. Higher Efficiency (43 to 45%)

Diesel power plants boast higher efficiency rates, typically ranging between 43% to 45%. This efficiency is a result of the diesel engine’s ability to convert a higher percentage of the fuel’s energy into electrical power. The high efficiency leads to lower fuel consumption per unit of electricity generated, which in turn reduces operating costs and environmental impact. This makes diesel power plants more economical to operate over time, especially when fuel costs are a significant concern.

4. Efficient Performance at Part Loads

Diesel power plants maintain efficient performance even at part loads. Unlike some other power generation systems that experience significant efficiency losses when not operating at full capacity, diesel engines can adjust to varying load conditions while maintaining good fuel economy and stable operation. This flexibility allows for more efficient use of fuel and resources, particularly in applications where power demand fluctuates.

5. Less Space Area Requirement

Diesel power plants require less space compared to other types of power plants, such as coal or nuclear facilities. The compact nature of diesel engines and the simplicity of the associated infrastructure mean that the overall footprint of a diesel power plant is smaller. This makes diesel power plants suitable for urban areas or locations where space is limited, and for applications where power generation needs to be close to the point of consumption.

6. Low Auxiliary Power Consumption

Auxiliary power consumption in diesel power plants is low. Auxiliary power refers to the electricity consumed by the supporting systems of a power plant, such as cooling systems, pumps, and control systems. Diesel power plants have fewer and more efficient auxiliary systems, which reduces the amount of power used for non-generative purposes. This increases the net power output of the plant and improves overall efficiency.

7. Capability to Run on Poor-Grade Fuels

Diesel engines can operate efficiently even on poor-grade fuels with high sulfur content. This capability provides operational flexibility, especially in regions where high-quality fuels are not readily available or are too expensive. The ability to use a wider range of fuel types makes diesel power plants more versatile and cost-effective, as they are less dependent on specific fuel supplies.

8. Optional Cooling Water Requirement

Diesel power plants can operate without the need for large quantities of cooling water, making them ideal for regions with limited water resources. Diesel engines can be equipped with air cooling systems, which use ambient air to dissipate heat instead of water. This feature is particularly advantageous in arid or water-scarce regions, where the availability of cooling water is a limiting factor for other types of power plants.

9. Short Start-Up Time

Diesel power plants have a short start-up time, allowing them to reach full operational capacity quickly. This quick start-up capability is crucial in situations where power needs to be restored rapidly, such as in emergency power generation or grid support during peak demand periods. The fast start-up also contributes to the reliability of diesel power plants as a backup power source.

10. Ease of Use

The operation of a DG (Diesel Generator) set is straightforward and user-friendly, requiring minimal specialized training. This ease of use simplifies maintenance and reduces the need for highly skilled operators. The simplicity of the diesel engine’s design, combined with robust and reliable components, ensures that diesel power plants can be operated efficiently with minimal downtime.

11. Dependability as a Power Source

Diesel power plants are one of the most dependable sources of power generation. The robust design of diesel engines, combined with their ability to operate in a wide range of conditions and with various fuel types, ensures consistent and reliable power output. This dependability makes diesel power plants an essential component in critical applications, such as hospitals, data centers, and military installations, where uninterrupted power supply is crucial.

Captive Power Plant Comparison: Advantages and Disadvantages

| Type of Captive Power Plant | Advantages | Disadvantages |

|---|---|---|

| Coal-Based Captive Power Plants | – High Energy Output – Cost-Efficient in coal-abundant regions – Established Technology | – Significant environmental impact (high carbon emissions) – Increasing regulatory challenges and costs |

| Natural Gas-Based Captive Power Plants | – Lower emissions compared to coal – High efficiency, especially in combined cycle – Flexible and quick ramp-up | – Dependence on natural gas availability and price – High initial infrastructure investment |

| Diesel-Based Captive Power Plants | – Ideal for smaller operations or as backup – Quick start-up capability | – Higher operating costs (expensive fuel) – Higher emissions of CO2, NOx, and particulates |

| Solar Captive Power Plants | – Zero emissions during operation – Low operating and maintenance costs – Eligible for government incentives | – Intermittent power supply (weather and time-dependent) – High initial capital investment |

| Wind Captive Power Plants | – Clean, renewable energy with no emissions – Scalable for various energy needs | – Site-specific (requires strong, consistent wind) – Variable power generation (intermittency) |

| Biomass Captive Power Plants | – Utilizes renewable organic waste – Carbon-neutral operation | – Requires reliable biomass supply chain – Higher maintenance due to fuel variability |

| Hybrid Captive Power Plants | – Combines reliability and cost optimization – Enhances energy security by diversifying sources | – More complex systems requiring advanced management – Higher initial capital investment due to multiple systems |

Energy-saving measures for DG sets

- Load conditions should be steady on the DGset.

- Improve the air filtration

- Follow the guidelines of oil companies for the fuel oil storage, handling, and preparation

- Consider the use of additives.

- Maintain the fuel injection equipment as per schedule.

- Comply with the maintenance checklist

- Use the waste heat recovery system.

- Consider the parallel operation for improved loading and fuel economy.

- Always carry out the DG set field trails regularly to monitor the DG set performance.

Conclusion

In conclusion, understanding the basics of diesel generators is crucial for anyone involved in their operation, maintenance, or selection. These reliable and robust machines are indispensable across various industries, providing critical backup power and ensuring operational continuity in the face of power outages. By grasping key concepts such as how diesel generators work, their components, and best practices for maintenance, you can ensure their efficient and long-lasting performance.

Whether you’re managing a large industrial setup or a small commercial operation, knowledge of diesel generators empowers you to make informed decisions, optimize performance, and reduce operational risks. Regular maintenance, proper load management, and adherence to safety protocols are the pillars of effective diesel generator management, ensuring that these vital machines serve your needs reliably for years to come.