Table of Contents

Emergency Generator Starting Methods

When it comes to starting a diesel engine on a ship, there are a few things that need to be done properly. In order to start your emergency generator on board a ship, you will need to know the diesel engine starting procedure. This post will cover the steps required to start your emergency generator on board a ship. We will also provide a guide on How To Start an Emergency Generator on the ship. This post will be a useful guide for young marine engineers starting their careers as a Marine Engineer

Preparation of Cooling Water System

1. Check the Cooling water tank level and fill it in if needed.

2. Prepare the cooling water system for starting.

3. Change the position of the valve from stop to operation.

4. Stop the system water leakages.

5. Check the cooling water system for proper venting.

6. Check the operating parameters.

7. Check the cleanness around the engine.

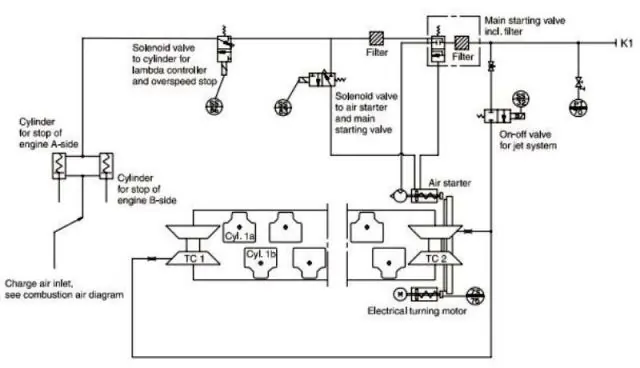

Starting Air system

Pre-heating of the Engine

1. Carry out the Preheating of the engine to protect the engine from abnormal thermal expansions.

2. Ensure the proper circulation of lubricating oil and fuel oil systems

3. Operate a cooling water heating system is installed.

To bring the operating parameters of the engine, it is required to heat the engine by circulation of cooling fluid at least one to two hours.

Make sure that the rotating parts of the Engine are free from obstacles.

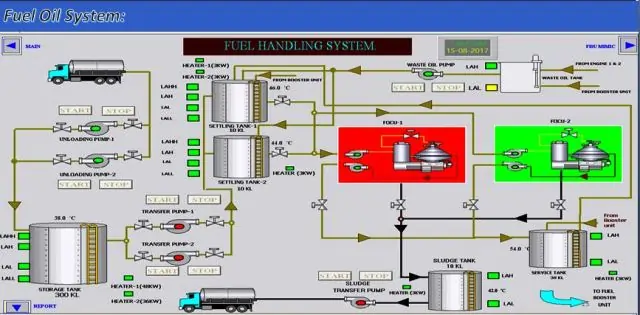

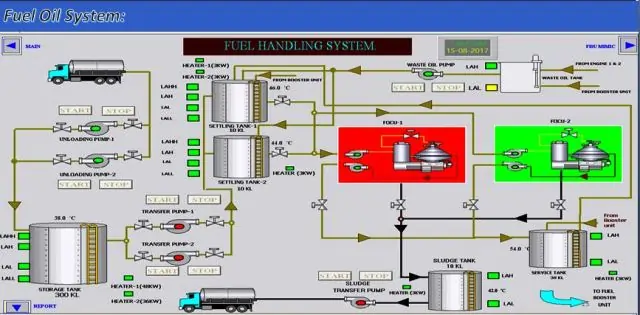

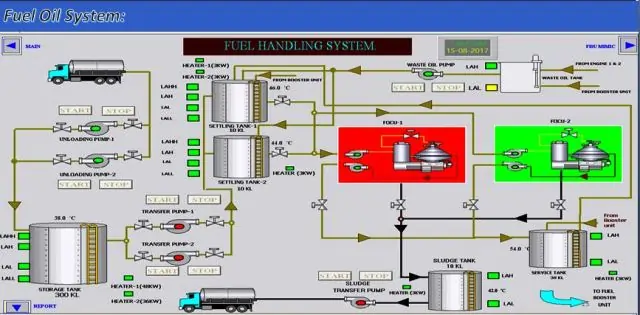

Preparation of Fuel System

1. Drain the water from the fuel system

2. Check and top up the fuel tank.

3. Check the Diesel cooling system

4. Check the fuel system if stopped.

5. Operate the fuel system if stopped.

6. Change the position of valves from stop to operating position.

7. Check for any leakage and correct it.

8. Check air venting in the system.

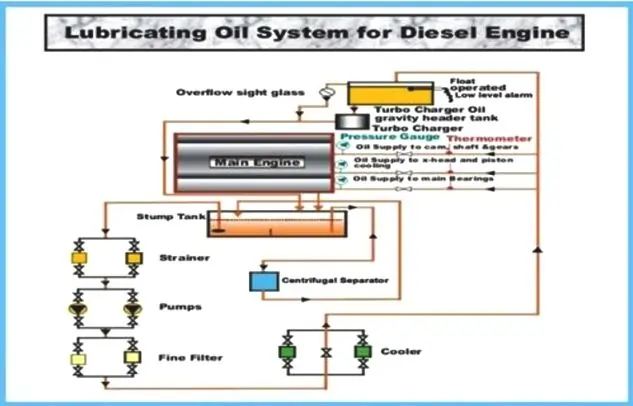

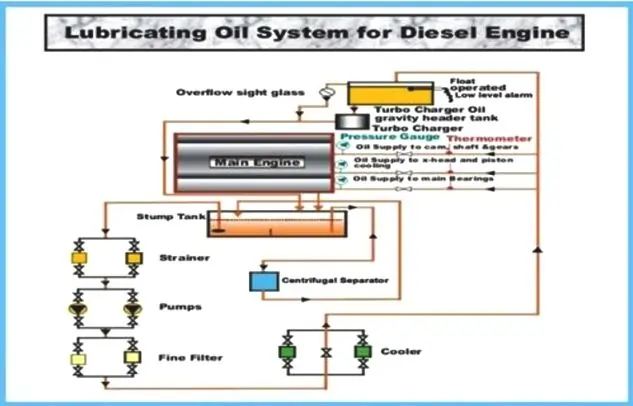

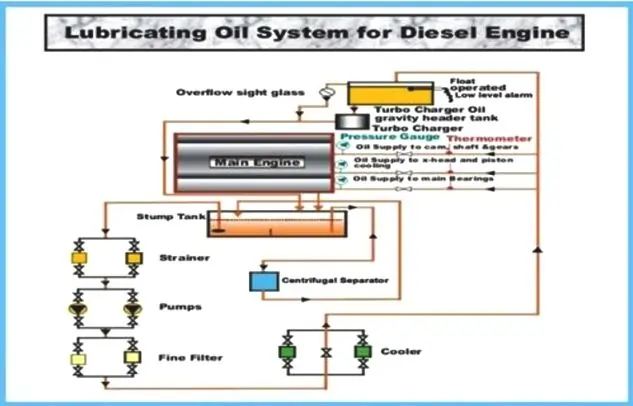

Preparation of Lubricating Oil System

1. Verify the date of the last sample taken for the check of quality.

2. Replace the oil filters. If the engine was overhauled or has been standing idle for long

3. Check oil sump tank level and fill if necessary.

4. Change the position of the valve to operations.

Pre-lubrication of the Engine

1. Heat the lubricating oil temperature to 40 ⁰C by heater.

2. Operate pre- Lubricating oil pump if stepped.

3. Check and correct any system leakage.

4. Check oil pressure rise and pre-lubricating oil condition.

Carry out the pre-lubrication of the engine at least 5 to 10 minutes prior to putting the engine in operation. If the Engine has been standstill for a long time or has been overhauled then make sure the oil flows from the following points.

1. Bearings

2. Pump and valve operating rollers.

3. Remove the tapes attached during maintenance.

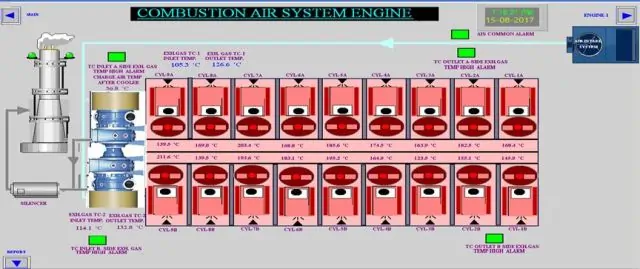

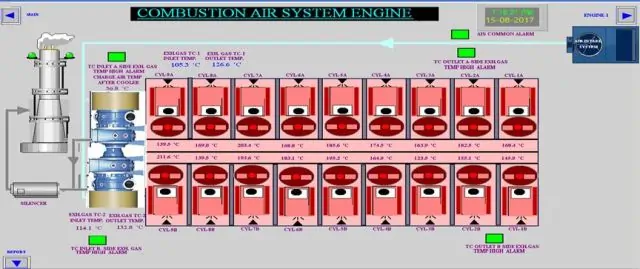

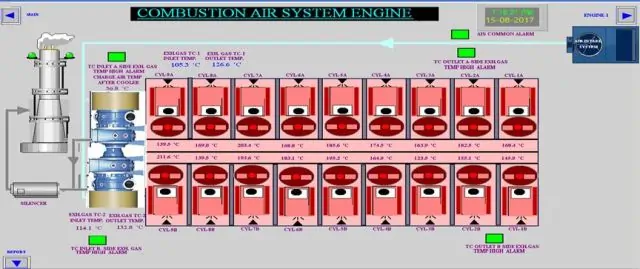

Intake Air and Exhaust system

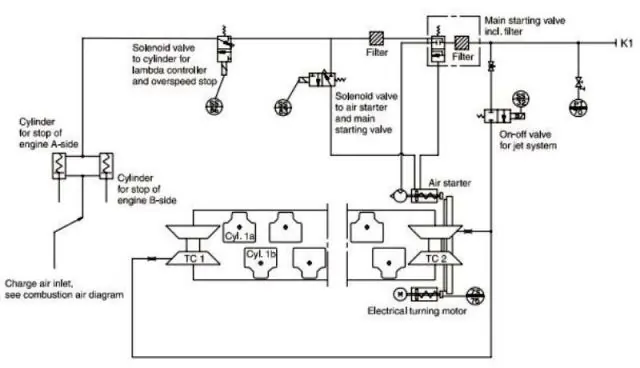

Open the indicator valves

- Lubricate the dry surface of liners by pouring 50 CC of oil through indicator cocks. Spray the oil under the piston and turn the engine.

- Rotate the engine with a shaft-barring arrangement. Turn the engine a few revolutions and check the freshness of moving parts. Turning is also done to ensure the non-presence of any fluid trapped in the combustion chambers. Proper checks during turning will prevent the engine from hydraulic locks and major damage to the components.

NOTICE:- If there is any sign of escaping fluid through the indicator cock, wrap the indicator cock Clean the fluid scattered around by waste cloth.

Rotate the crankshaft by 2 to 3 revolutions for observing any fluid emerging from cylinders.

Disengage from turning gear

Air System readiness for How To Start Emergency Generator.

- Remove the condensate from the Air receiver and

- Check the air filters

- Check and fill the starting air bottle to 20-30 bars.

- check the air pressure for the control system of the engine.

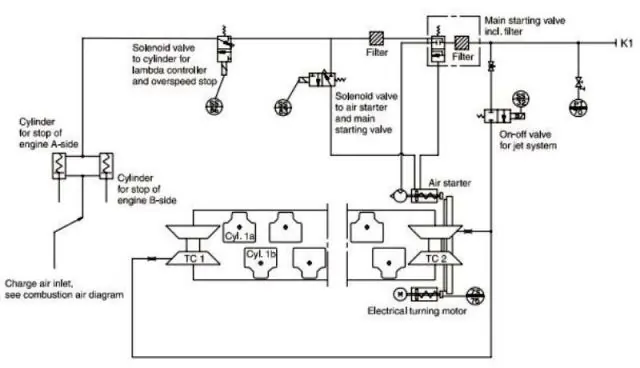

Fuel regulating System preparedness

1. Check the regulating rod for the smooth and free moment from the governor to all the fuel racks of High pressure fuel injection pumps for How To Start Emergency Generator

2. Check and reset the operation of the stop button for emergency. Operate the emergency stop button keeping the fuel control rod to maximum position. During this operation check, all the fuel racks should move to maximum zero positon. This check is necessary to ensure the stopping of engine in the event of any abnormality of the engine.

3. Check the flexibility of each rack of the fuel injection pump. Check the return of fuel racks to its original position by manualy pulling the rack from one position to the other position.

4. Check mechanical fuel limiter for overload (set to 110 % load).

5. NOTICE; If the mechanical fuel limiter is not set correctly, the engine may be seriously damaged

6. Set the mechanical fuel limiter on governor to 30-50% of the load limit.