Turbocharger Working

Turbochargers have revolutionized engine performance, enhancing power and efficiency by forcing more air into the combustion chamber. This process not only boosts horsepower but also improves fuel economy, making turbochargers essential components in both automotive and industrial engineering. As engines strive for greater performance and stricter emissions standards, understanding turbochargers has become crucial for engineers.

In this comprehensive guide, we will delve into the working principles of turbochargers, focusing on their application in diesel engines. You’ll learn about the construction and types of turbochargers, including Variable Geometry Turbochargers (VGT), which offer superior efficiency and performance. Additionally, we will explore the concept of K Value in turbochargers, common issues faced, and methods to check turbocharger efficiency during operation. By the end of this guide, you’ll have a thorough understanding of turbochargers, equipping you with the knowledge to optimize and troubleshoot these vital components in your engineering projects.

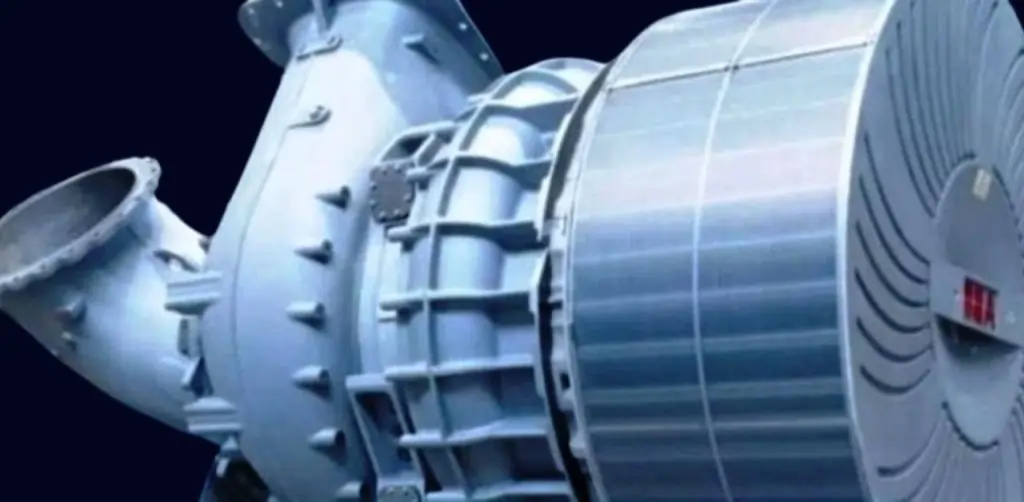

Turbocharger Components and Working Principle

A turbocharger (TC) is a device that increases an internal combustion engine’s efficiency and power output by forcing extra compressed air into the combustion chamber. Here, we provide detailed descriptions of various components involved in a turbocharger and their working principles.

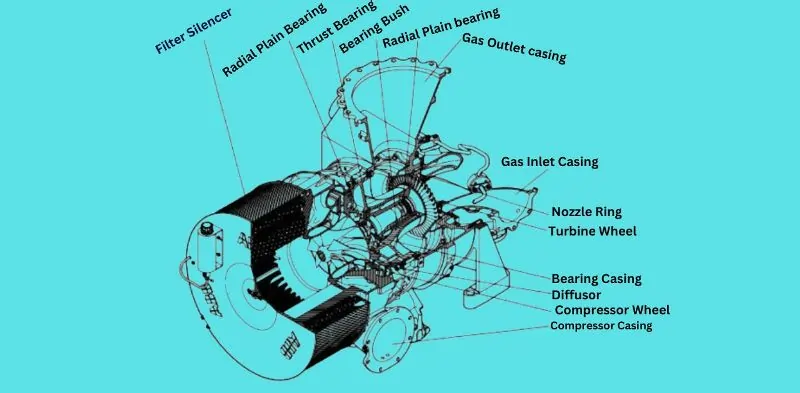

1. Filter Silencer

Description: The filter silencer combines the functions of an air filter and a silencer. It filters out impurities from the incoming air and reduces the noise generated by the airflow. Working Principle: As air enters the turbocharger, it passes through the filter silencer, which removes particulates and muffles the sound of the intake, ensuring clean and quiet operation.

2. Radial Plain Bearing

Description: Radial plain bearings are cylindrical bearings that support the rotating shaft of the turbocharger, allowing smooth radial movement. Working Principle: These bearings reduce friction between the rotating shaft and the bearing housing, supporting the radial load and ensuring smooth rotation of the turbocharger components.

3. Thrust Bearing

Description: Thrust bearings support axial loads on the turbocharger’s rotating assembly, preventing axial displacement. Working Principle: By providing a surface for the axial forces to act upon, thrust bearings ensure the shaft remains in its proper position, reducing wear and enhancing stability.

4. Bearing Bush

Description: A bearing bush is a cylindrical component that provides a low-friction interface between the rotating shaft and the stationary housing. Working Principle: It supports the shaft and reduces wear by providing a smooth, low-friction contact surface, ensuring efficient operation of the turbocharger.

5. Gas Outlet Casing

Description: The gas outlet casing is the housing through which the exhaust gases exit the turbocharger. Working Principle: It directs the exhaust gases from the turbine to the exhaust system, ensuring efficient gas flow and minimizing back pressure.

6. Gas Inlet Casing

Description: The gas inlet casing directs exhaust gases from the engine into the turbine housing of the turbocharger. Working Principle: It ensures a smooth and directed flow of exhaust gases into the turbine, maximizing energy transfer to the turbine wheel.

7. Nozzle Ring

Description: The nozzle ring contains a series of vanes that direct exhaust gases onto the turbine wheel. Working Principle: By controlling the angle and flow of exhaust gases, the nozzle ring optimizes the energy transfer to the turbine wheel, enhancing the turbocharger’s efficiency and performance.

8. Turbine Wheel

Description: The turbine wheel is a key component that converts the energy from exhaust gases into mechanical energy to drive the compressor wheel. Working Principle: As exhaust gases pass over the turbine blades, they cause the wheel to spin, transferring energy to the shaft and subsequently driving the compressor wheel.

9. Bearing Casing

Description: The bearing casing houses the bearings that support the turbocharger shaft. Working Principle: It provides a secure environment for the bearings, ensuring proper alignment and lubrication, which are critical for smooth operation and longevity of the turbocharger.

10. Diffusor

Description: The diffusor is a component that decelerates and increases the pressure of the compressed air exiting the compressor wheel. Working Principle: By converting the high-velocity, low-pressure air into low-velocity, high-pressure air, the diffusor enhances the efficiency of the turbocharger and ensures optimal air delivery to the engine.

11. Compressor Wheel

Description: The compressor wheel is a rotating component that compresses the incoming air and delivers it to the engine. Working Principle: Driven by the turbine wheel via the shaft, the compressor wheel draws in ambient air, compresses it, and forces it into the engine’s intake manifold, increasing the air density and allowing for more fuel to be burned, thereby increasing power output.

12. Compressor Casing

Description: The compressor casing houses the compressor wheel and guides the compressed air to the engine. Working Principle: It encloses the compressor wheel, ensuring the air is efficiently directed from the inlet to the outlet, minimizing losses and enhancing the overall performance of the turbocharger.

Working Principle of Turbocharger

The turbocharger operates on the principle of using exhaust gases to drive a turbine wheel connected to a compressor wheel via a common shaft. Here’s a step-by-step outline of its working:

- Exhaust Gas Entry: Exhaust gases from the engine enter the turbocharger through the gas inlet casing.

- Energy Conversion: The exhaust gases pass through the nozzle ring, which directs them onto the turbine wheel. The energy from the exhaust gases causes the turbine wheel to spin.

- Shaft Rotation: The turbine wheel is connected to the compressor wheel via a shaft. As the turbine wheel spins, it drives the compressor wheel.

- Air Compression: The spinning compressor wheel draws in ambient air through the filter silencer, compresses it, and forces it into the engine’s intake manifold.

- Increased Air Density: The compressed air has a higher density, allowing more fuel to be injected and burned, resulting in increased engine power and efficiency.

- Exhaust Gas Exit: After passing through the turbine wheel, the exhaust gases exit the turbocharger through the gas outlet casing.

Methods of Turbocharging for Diesel Engines

Turbocharging is a critical technology in diesel engines, significantly enhancing their efficiency and power output. There are various methods of turbocharging, each with unique principles and applications. The three main methods are Constant Pressure Turbocharging, Pulse Turbocharging, and Pulse Converter Turbocharging. Below is a detailed description of each method, including their working principles and benefits.

1. Constant Pressure Turbocharging

Description: Constant Pressure Turbocharging is a method where the exhaust gases from all cylinders are collected in a common manifold at nearly constant pressure before entering the turbocharger. Working Principle:

- Exhaust Gas Collection: Exhaust gases from each cylinder are directed into a common exhaust manifold.

- Pressure Stabilization: The manifold design ensures that the pressure of the exhaust gases remains relatively constant.

- Turbine Drive: These gases then drive the turbine wheel of the turbocharger at a constant pressure, which in turn drives the compressor wheel.

- Air Compression: The compressor wheel draws in ambient air, compresses it, and supplies it to the engine at a higher pressure, increasing the air density.

- Benefits: This method provides smooth and consistent turbocharging, which is beneficial for engines operating under steady load conditions. It ensures uniform exhaust gas flow and pressure, leading to more efficient and stable turbocharger operation.

2. Pulse Turbocharging

Description: Pulse Turbocharging utilizes the pressure pulses of the exhaust gases from individual cylinders to drive the turbocharger. This method exploits the high energy of exhaust pulses for efficient turbine operation. Working Principle:

- Exhaust Pulse Utilization: Exhaust gases from each cylinder are directed into separate exhaust manifolds or ducts. The design allows for the exhaust pulse energy to be used effectively.

- Sequential Pulse Driving: The high-energy exhaust pulses from each cylinder sequentially drive the turbine wheel, maximizing the energy transfer.

- Reduced Lag: Due to the utilization of pulse energy, there is minimal lag in turbocharger response, providing immediate boost pressure.

- Air Compression: The compressor wheel, driven by the turbine, compresses the intake air and supplies it to the engine, enhancing its performance.

- Benefits: Pulse Turbocharging is particularly effective at low engine speeds, providing quick response and improved transient performance. It is suitable for engines with varying load conditions, such as in automotive applications.

3. Pulse Converter Turbocharging

Description: Pulse Converter Turbocharging combines elements of both constant pressure and pulse turbocharging. It uses a specialized manifold design to optimize the use of exhaust pulses and maintain relatively stable pressure. Working Principle:

- Manifold Design: The exhaust manifold is designed with a pulse converter, which balances the pressure pulses and maintains a degree of constant pressure.

- Pulse and Pressure Combination: This design allows for effective use of high-energy exhaust pulses while stabilizing pressure to ensure efficient turbine operation.

- Enhanced Energy Transfer: The combination of pulse energy and stabilized pressure leads to optimal energy transfer to the turbine wheel.

- Air Compression: The compressor wheel, driven by the turbine, compresses the intake air and supplies it to the engine, improving its efficiency and power output.

- Benefits: Pulse Converter Turbocharging provides the benefits of both pulse and constant pressure turbocharging. It offers quick response and improved efficiency across a wide range of engine speeds and load conditions, making it suitable for both steady-state and dynamic applications.

Construction of a Turbocharger

A turbocharger is a crucial component in diesel engines, designed to improve performance and efficiency. This section will outline the main parts of a turbocharger and the materials used, highlighting their significance without duplicating the detailed component descriptions provided earlier.

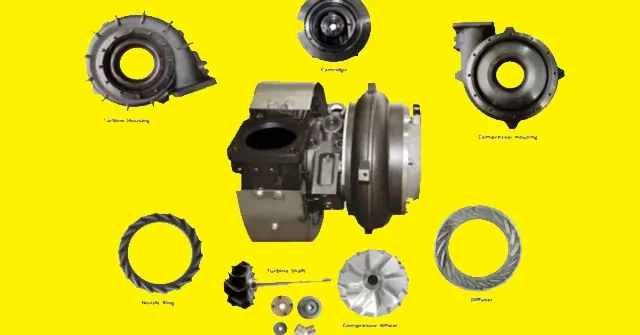

Turbocharger Parts And Function

Main Parts of a Turbocharger

- Compressor Housing

- Compressor Wheel

- Turbine Housing

- Turbine Wheel

- Center Housing (Bearing Housing)

- Bearings (Radial and Thrust Bearings)

- Shaft

- Nozzle Ring

- Wastegate

- Labyrinth Seal

Materials Used and Their Significance

- Compressor Housing

- Materials Used: Typically made from aluminum alloys.

- Significance: Aluminum’s lightweight and excellent thermal conductivity help dissipate heat generated during air compression.

- Compressor Wheel

- Materials Used: Usually made from aluminum alloys or titanium.

- Significance: Aluminum reduces inertia and improves response time, while titanium offers superior strength-to-weight ratio and higher temperature resistance for high-performance applications.

- Turbine Housing

- Materials Used: Cast iron or high-temperature stainless steel alloys.

- Significance: These materials withstand high temperatures and corrosion from exhaust gases, ensuring durability and longevity.

- Turbine Wheel

- Materials Used: Inconel (a nickel-chromium-based superalloy).

- Significance: Inconel maintains its strength and corrosion resistance at high temperatures, crucial for handling hot exhaust gases.

- Center Housing (Bearing Housing)

- Materials Used: Cast iron or aluminum alloys.

- Significance: Cast iron provides strength and thermal resistance, while aluminum is used in applications where weight reduction is critical.

- Bearings (Radial and Thrust Bearings)

- Materials Used: High-grade steel or ceramic.

- Significance: Steel offers durability and wear resistance, while ceramic bearings provide lower friction and higher temperature tolerance, improving efficiency and lifespan.

- Shaft

- Materials Used: High-strength steel alloys.

- Significance: Steel alloys are chosen for their high tensile strength and fatigue resistance, essential for the high-speed rotation of the turbocharger.

- Nozzle Ring

- Materials Used: Stainless steel or Inconel.

- Significance: These materials withstand high temperatures and erosion from high-velocity exhaust gases, ensuring efficient energy transfer and durability.

- Wastegate

- Materials Used: Stainless steel or nickel-based alloys.

- Significance: These materials resist high temperatures and corrosion, providing reliable operation over the turbocharger’s lifespan.

- Labyrinth Seal

- Function: Provides a non-contact sealing solution between high-pressure and low-pressure zones within the turbocharger, preventing oil leakage.

- Materials Used: Stainless steel or high-strength alloys.

- Significance: These materials offer excellent wear resistance and durability, ensuring a long-lasting seal under high-speed and high-temperature conditions.

Types of Turbochargers

Turbochargers come in various designs, each tailored to specific applications and performance requirements. Two primary types of turbochargers used in diesel engines are the Axial Flow Type (TCA Type) and Radial Flow Type (TCR Type). Both types operate on similar principles but differ in their construction and how they handle exhaust gases. Below is a detailed description of each type, their working principles, and their unique characteristics.

1. Axial Flow Type (TCA Type Turbocharger)

Description: The Axial Flow Turbocharger, often referred to as the TCA Type, is designed to handle large volumes of exhaust gases with high efficiency. This type is commonly used in large diesel engines, such as those found in marine and power generation applications.

Working Principle:

- Nozzle Ring: The exhaust gases first pass through a nozzle ring, where their pressure energy is converted into kinetic energy, increasing their velocity.

- Gas Direction: The high-velocity gas is then directed onto the turbine blades. The turbine blades are angled in such a way that as the gas flows over them, it changes direction.

- Force and Rotation: The change in direction of the gas imparts a force onto the turbine blades, causing the turbine wheel to turn.

- Compressor Drive: The rotating turbine wheel is connected to a shaft that drives the compressor wheel, which compresses the intake air and forces it into the engine.

Advantages:

- High Efficiency: Capable of handling large volumes of exhaust gases with minimal pressure loss.

- Robust Design: Suitable for heavy-duty applications with high thermal and mechanical stresses.

- Improved Performance: Provides a continuous and smooth power boost, ideal for steady-state operation.

2. Radial Flow Type (TCR Type Turbocharger)

Description: The Radial Flow Turbocharger, or TCR Type, is designed for versatility and is widely used in both automotive and industrial diesel engines. It is known for its compact design and quick response characteristics.

Working Principle:

- Nozzle Ring: Similar to the axial flow type, exhaust gases pass through a nozzle ring where their pressure energy is converted into kinetic energy.

- Gas Direction: The high-velocity gas is directed radially onto the turbine wheel. As the gas passes through the turbine wheel, it changes direction radially (from a radial inflow to an axial outflow).

- Force and Rotation: The change in direction of the gas flow generates an impulsive force on the turbine blades, causing the turbine wheel to rotate.

- Compressor Drive: The rotating turbine wheel drives the compressor wheel via a common shaft, compressing the intake air and supplying it to the engine.

Advantages:

- Compact Design: The radial flow design allows for a more compact and lightweight turbocharger, which is ideal for space-constrained applications.

- Quick Response: Offers faster spool-up times, providing quick boost pressure and improved throttle response.

- Versatility: Suitable for a wide range of applications, from automotive engines to industrial machinery.

Turbocharger Bearings

Bearings are crucial components in turbochargers, playing a significant role in supporting the rotating assembly, minimizing friction, and ensuring smooth operation. Two primary types of bearings used in turbochargers are Ball/Roller type bearings and Journal sleeve/Bush-type bearings. Each type has its unique characteristics, advantages, and applications. Below is a detailed description of these two types of bearings.

1. Ball/Roller Type Bearings

Description: Ball and roller type bearings are rolling-element bearings that use balls or rollers to maintain the separation between the bearing races. These bearings are known for their low friction, high-speed capabilities, and durability.

Working Principle:

- Construction: Ball bearings use spherical balls, while roller bearings use cylindrical rollers between the inner and outer races.

- Load Distribution: The rolling elements (balls or rollers) distribute the load evenly across the bearing surfaces, reducing friction and wear.

- Rotation: As the turbocharger shaft rotates, the balls or rollers roll between the races, providing smooth and efficient movement.

Advantages:

- Low Friction: The rolling contact significantly reduces friction compared to sliding contact in journal bearings.

- High-Speed Capability: Suitable for high-speed applications due to their ability to maintain stability and minimize friction at high rotational speeds.

- Durability: Can handle both radial and axial loads efficiently, enhancing the turbocharger’s longevity and reliability.

- Reduced Lag: Provides quick response and faster spool-up times, improving engine performance.

Applications:

- High-Performance Engines: Commonly used in automotive turbochargers, particularly in high-performance and racing applications where quick response and high efficiency are crucial.

- Aerospace and Industrial Turbochargers: Employed in applications requiring high-speed operation and reliability.

2. Journal Sleeve/Bush-Type Bearings

Description: Journal sleeve or bush-type bearings, also known as plain bearings, use a thin layer of oil to provide a low-friction interface between the rotating shaft and the stationary housing. These bearings are simple in design and widely used in various turbocharger applications.

Working Principle:

- Construction: Consists of a cylindrical sleeve or bushing made from materials such as bronze or babbitt, which supports the rotating shaft.

- Hydrodynamic Lubrication: As the shaft rotates, a thin film of oil is maintained between the shaft and the bearing surface. The oil film provides a cushioning effect, reducing metal-to-metal contact and minimizing friction.

- Load Support: The oil film also helps distribute the load evenly across the bearing surface, enhancing its load-carrying capacity.

Advantages:

- Simplicity: Simple construction with fewer components, making it easy to manufacture and maintain.

- Cost-Effective: Generally more affordable compared to rolling-element bearings.

- Good Load Capacity: Capable of handling significant radial loads, making them suitable for heavy-duty applications.

- Durability: When properly lubricated, journal bearings can offer long service life with minimal wear.

Applications:

- Heavy-Duty Diesel Engines: Commonly used in marine, industrial, and commercial vehicle turbochargers, where durability and load-carrying capacity are prioritized.

- Automotive Turbochargers: Used in standard automotive applications where cost-effectiveness and reliability are essential.

Variable Geometry Turbocharger (VGT)

Variable Geometry Turbochargers (VGT) represent a significant advancement in turbocharging technology, offering enhanced performance and efficiency across a wide range of engine speeds and loads. Below is a detailed explanation of VGT technology, its benefits, and its applications in modern engines.

Explanation of VGT Technology

Description: A Variable Geometry Turbocharger (VGT) features adjustable vanes or nozzles within the turbine housing. These vanes alter the angle and flow of exhaust gases onto the turbine wheel, optimizing the turbocharger’s performance under different operating conditions.

Working Principle:

- Adjustable Vanes: The VGT has a series of movable vanes around the turbine wheel. These vanes can change their angle to control the flow of exhaust gases.

- Actuator Mechanism: An actuator, controlled by the engine’s electronic control unit (ECU), adjusts the position of the vanes based on the engine’s current speed, load, and other parameters.

- Variable Geometry: At low engine speeds, the vanes close to a narrower angle, creating a smaller nozzle area. This increases the velocity of exhaust gases hitting the turbine wheel, improving low-end torque and reducing turbo lag. At higher engine speeds, the vanes open wider, allowing more exhaust gases to flow through, preventing excessive backpressure and maintaining optimal boost pressure.

Benefits of VGT Technology

- Improved Low-End Torque:

- Enhanced Performance: By optimizing exhaust gas flow at low engine speeds, VGTs provide significant improvements in low-end torque. This results in better acceleration and responsiveness, especially from a standstill or low speeds.

- Reduced Turbo Lag:

- Quicker Response: The ability to adjust the vane angles dynamically reduces the time it takes for the turbocharger to spool up, minimizing turbo lag. This ensures that boost pressure is available more quickly when the driver demands power.

- Optimal Boost Control:

- Efficiency: VGTs maintain optimal boost pressure across a wide range of engine speeds and loads. This leads to better engine efficiency, fuel economy, and reduced emissions.

- Versatility:

- Wide Operating Range: VGTs are effective across a broad range of operating conditions, making them suitable for both low-speed city driving and high-speed highway cruising.

- Enhanced Fuel Efficiency:

- Lower Consumption: By optimizing air-fuel mixture and combustion efficiency, VGTs contribute to better fuel economy, which is crucial for both passenger vehicles and commercial applications.

Applications of VGT in Modern Engines

- Passenger Vehicles:

- Performance and Efficiency: VGTs are widely used in modern passenger vehicles to enhance performance, drivability, and fuel efficiency. They are particularly beneficial in diesel engines, which require efficient turbocharging to meet emission standards and provide good torque characteristics.

- Commercial Vehicles:

- Heavy-Duty Applications: VGTs are also employed in commercial vehicles, including trucks and buses. The improved torque and efficiency help in handling heavy loads and maintaining fuel economy, which are critical for commercial operations.

- Marine Engines:

- Marine Propulsion: In marine applications, VGTs provide the necessary boost for efficient operation of large diesel engines used in ships and boats. The technology helps in optimizing fuel consumption and performance, which is vital for long voyages and heavy-duty marine operations.

- Industrial Engines:

- Stationary and Mobile Machinery: VGTs are used in industrial engines for applications such as power generation, construction machinery, and agricultural equipment. The ability to adapt to varying load conditions makes VGTs ideal for such applications, ensuring reliable performance and fuel efficiency.

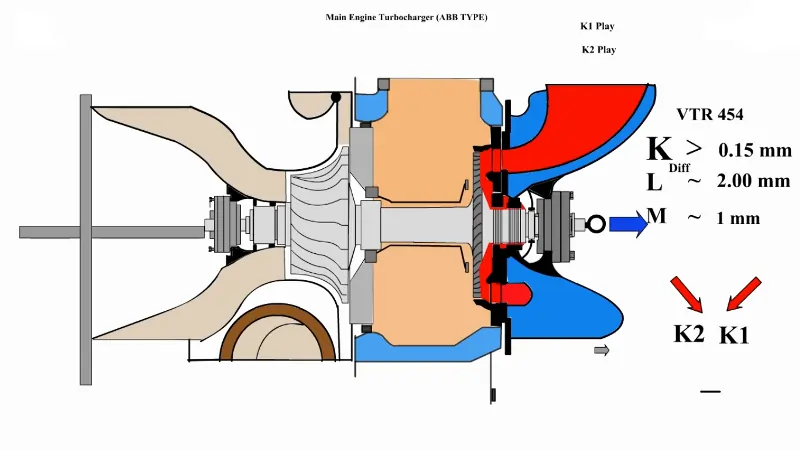

K Value in Turbochargers

In turbocharger design, precise measurements and tolerances are critical to ensuring reliable and efficient operation. One such crucial measurement is the K Value, which is the distance between the rotor shaft end and the bearing cover flange. This measurement is taken from the blower side and plays a significant role in the operational integrity of the turbocharger.

Definition and Measurement of K Value

Definition: The K Value is the distance between the end of the rotor shaft and the bearing cover flange, measured from the blower side of the turbocharger. This measurement is crucial for maintaining proper clearances within the turbocharger assembly.

Measurement:

- Procedure: To measure the K Value, a precise measuring tool, such as a depth micrometer or caliper, is used to determine the distance from the end of the rotor shaft to the bearing cover flange.

- Reference Points: The measurement is taken with reference to the blower side, ensuring that the correct clearance is maintained between the rotor shaft end and the bearing cover flange.

Importance of K Value

| Aspect | Description |

|---|---|

| Prevention of Contact | The primary importance of maintaining the correct K Value is to prevent contact between the impeller and the blower casing. If the thrust bearing wears out, the rotor shaft can move axially. The K Value ensures there is enough clearance to avoid such contact, which could cause severe damage to the turbocharger components. |

| Thrust Bearing Wear Compensation | As the thrust bearing wears over time, it can allow for axial movement of the rotor shaft. The K Value is designed to accommodate this wear, preventing the rotor shaft from moving too far and causing mechanical interference within the turbocharger. |

| Operational Efficiency | Proper K Value measurement and maintenance help in sustaining the designed clearances within the turbocharger. This ensures that the rotating components have adequate space to operate without excessive friction or interference, promoting efficient performance. |

| Reliability and Longevity | By ensuring that the rotor shaft does not come into contact with the blower casing, the K Value helps protect critical turbocharger components from premature wear and damage, thereby extending the operational life of the turbocharger. |

| Performance Optimization | Maintaining the correct K Value contributes to the stable operation of the turbocharger. It helps in reducing vibrations and noise, thereby enhancing the overall performance of the engine. |

K Value Measurement Procedure for Turbochargers

Measuring the K value in a turbocharger is a critical procedure to ensure proper clearance and prevent mechanical interference. The K value is the distance between the rotor shaft end and the bearing cover flange. Here is a detailed step-by-step procedure to measure the K value:

Step-by-Step Procedure

- Preparation:

- Remove any irrelevant parts to facilitate clear and easy measurement.

- Ensure you have the necessary tools as specified by the manufacturer.

- Remove the Nut Locking Nut:

- Remove the nut locking nut on both sides of the rotor shaft.

- Withdraw Securing Bolts and Bearing:

- Using the tools provided by the manufacturer, withdraw the hexagon securing bolts.

- Remove the bearing. About 5 to 6 mm of movement is enough. Keep the removed parts aside.

- Consult the Maker’s Instruction Book:

- For specific details relevant to your ship and turbocharger model, consult the maker’s instruction book. Some models may require additional steps or the removal of extra components.

- Ensure Rotor Free Movement:

- The rotor should be free to move without obstruction from any component, such as the bearing or lock washers. Verify this by consulting the instruction book.

- Safety Precautions:

- To be on the safe side, withdraw the securing bolts on the turbine side as well. The shaft should be free to slide to accommodate thermal expansion.

- Measure the Initial K Value:

- Push the rotor towards the blower side until it stops when the forward part of the blower touches the static casing.

- Measure this position using a precise measuring device. Record this measurement as K1.

- Measure the K1 Value:

- Note down the K1 value in a diary. This is the measurement when the rotor is pushed towards the air inlet side.

- Pull the Rotor Towards the Turbine End:

- Pull the rotor towards the turbine end until it touches the stationary part on the aft side. The rotor should not move any further.

- Measure this position and record it as K2.

- Calculate L and M Values:

- L Value: When the shaft is pushed and K1 is obtained, calculate L using the formula: L=K−K1L = K – K1L=K−K1. This represents the clearance before dismantling the turbocharger.

- M Value: When the shaft is pulled and K2 is obtained, calculate M using the formula: M=K2−KM = K2 – KM=K2−K. This represents the clearance when the shaft was boxed up in the correct position.

- Record and Analyze Measurements:

- Record the K1 and K2 values. Compare these values to the original K value.

- The clearances, L (forward part of the casing) and M (aft part of the blower wheel), are critical to ensure the rotor is properly positioned.

- Check for Discrepancies:

- If there is a significant difference (more than 0.15 mm) between the K values before and after assembly, it indicates a potential issue. Recheck or dismantle and reassemble as needed.

- Ensure Consistency:

- The K value should remain constant unless major components like the rotor or air inlet casing are changed. Always measure the K value before dismantling and after assembly.

- Final Verification:

- Verify the K value is stamped on the inside of the casing cover. This value indicates the L and M clearances are satisfactory.

- If the K value differs significantly after reassembly (more than 0.2 mm), something is wrong, and further inspection is needed.

- Concluding Remarks:

- Always consult the specific manual for your turbocharger model before proceeding with any maintenance.

- The K value measurement ensures the turbocharger is assembled correctly, preventing damage and ensuring efficient operation.

Most Common Issues with Turbochargers: Surging

Surging is a common and potentially damaging phenomenon in turbocharged diesel engines. Understanding the conditions that lead to surging and identifying its root causes is essential for preventing this issue and ensuring the efficient operation of the turbocharger.

Understanding Surging in Turbocharging Diesel Engines

Surging occurs when there is an imbalance in the pressure and mass flow through the turbocharger, leading to unstable airflow and oscillations. This can be illustrated by considering the following conditions:

- P1: Compressor outlet pressure.

- P2: Pressure from Charge Air Cooler.

- M: Mass Flow.

Case Scenarios:

- Case A: P2/P1 = 1, and M is on the Higher Side

- Condition: Both pressures are equal, and the mass flow of air is high.

- Implication: Indicates no restriction to the mass flow; the system is operating normally.

- Case B: P2/P1 ≥ 1, and M is Lower

- Condition: Pressure ratio is equal to or greater than one, but mass flow is reduced.

- Implication: Indicates some restriction in the system, potentially leading to reduced efficiency.

- Case C: P2/P1 < 1, and M is Negligible

- Condition: The pressure ratio is less than one, and mass flow is significantly decreased.

- Implication: This condition is indicative of surging. When the pressure ratio drops and mass flow is negligible, unstable airflow can cause the turbocharger to surge.

Leading Causes of Turbocharger Surging

- High Exhaust Backpressure

- Description: Excessive pressure in the exhaust system restricts the flow of exhaust gases, leading to surging.

- Choked Scavenged Ports

- Description: Blockages or restrictions in the scavenged ports reduce the flow of exhaust gases, causing pressure imbalances.

- Excessive Turbo Outlet Restriction

- Description: Any restriction at the turbo outlet can impede airflow, leading to unstable operation and surging.

- Fouled Nozzle Ring Blades

- Description: Deposits on the nozzle ring blades hinder the smooth flow of exhaust gases, affecting the turbine’s performance.

- Leaky Exhaust Valves

- Description: Leaks in the exhaust valves can lead to inconsistent pressure and airflow, contributing to surging.

- Misfiring in One or More Cylinders

- Description: Misfiring disrupts the balance of exhaust gases, causing fluctuations in pressure and mass flow.

- Fouled Compressor Wheel Blades

- Description: Deposits on the compressor wheel blades reduce efficiency and can lead to unstable airflow.

- Choked Charge Air Cooler

- Description: Blockages in the charge air cooler restrict airflow, leading to pressure imbalances.

- Turbo Outlet Pressure Leak

- Description: Leaks at the turbo outlet reduce the effective pressure, contributing to surging.

- Erratic Engine or Engine Control Operation

- Description: Inconsistent engine performance or control issues can lead to fluctuating exhaust gas flow and surging.

- A Muffler with a Large Amount of Water in It

- Description: Water accumulation in the muffler restricts exhaust flow, leading to increased backpressure and surging.

- Sudden Load Change

- Description: Rapid changes in engine load can disrupt the balance of airflow and pressure, causing surging.

- Fire in Scavenge Space or Exhaust Trunking

- Description: Fires can cause severe disruptions in airflow and pressure, leading to surging.

- A Collapsed Air Cleaner Filter Element

- Description: A collapsed filter restricts the intake airflow, leading to pressure imbalances.

- Several Cylinders Misfiring

- Description: Multiple misfiring cylinders significantly disrupt exhaust gas flow, leading to severe surging.

- Badly Worn Fuel Control Linkage

- Description: Worn linkages can lead to inconsistent fuel delivery and engine performance, causing surging.

- Improperly Adjusted Governor

- Description: An improperly adjusted governor can cause unstable engine speeds and airflow, contributing to surging.

- Worn Governor Actuator

- Description: A worn actuator can lead to inconsistent engine control, affecting exhaust gas flow.

- Voltage Regulator with Intermittent Output Fault

- Description: Intermittent faults in the voltage regulator can cause unstable engine operation, leading to surging.

- Damaged Turbine and Compressor Blades

- Description: Physical damage to the blades reduces efficiency and can cause unstable airflow, leading to surging.

Checking Turbocharger Efficiency While in Operation

Turbine Efficiency= Turbine Efficiency (Drop in Turbine side) + Blower Efficiency (Filter chocked) + Mechanical Efficiency

- If the temperature difference is more than, it indicates that the Turbocharger is running efficiently. If the difference in temperature is more than it suggests, the fouling of internal Turbocharger moving parts

- The readings of the Manometer at the compressor side. There is an absolute pressure gauge before the filter, and after the filter, a manometer is installed. The reading at the Manometer will indicate the choking of the filter. If the filter is choked, then the air-induced mass flow will be less, and combustion will be poor.

- If the charge air cooler is choked, then the air-induced density will be less and will result in poor combustion. The difference in water temperature between the inlet and Outlet of the charge air cooler should not be ˂ 50C

- The temperature difference of air across the charge air cooler should be between 350C to 400C.

Guidelines for Dealing with a Blocked Turbocharger in Diesel Engines

No action is to be taken for the 4-stroke engine with one turbocharge and separate air receiver. It is possible to run the engine as a naturally aspirated engine.

Common air receiver

Remove the compensator of the broken turbocharger and isolate the air ducting on the engine side.

Power pulses will be applied on the locked rotor for the pulse-type turbocharger. Maintain the following operating parameters.

- The engine can be operated up to a maximum of 25% engine load.

- The pressure in the charge-air receiver must not exceed 0.9 bar

- With pulse supercharging (2…4 gas inlets), the engine can be operated up to a maximum of 20% engine load.

- The pressure in the charge-air receiver must be less than 0.5 bar

Turbine Side water washing

Blog Post Conclusion

In the end, think of turbochargers as secret helpers for marine diesel engines, giving them more power and efficiency. Exhaust gases come out to rotate the turbine and the compressor gets rotated which is mounted on the same shaft. The compressor compresses the air and sends it to the Engine. More air induced in the cylinder will help in burning more fuel efficiently and increasing the Engine efficiency.

Understanding the working of a Turbocharger is a bit complex since these are highly rotating machines.

In this blog post, we have tried to explain the working of a Turbocharger in a very simple easy-to-understand way for Beginners. Happy learning!!

FAQ on ” How Does A Turbo Work”

Q: What is a turbocharger?

A: A turbocharger is a device that boosts the power of an engine.

Q: How does a turbocharger work?

A: It uses exhaust gases to spin a fan, which adds more air to the engine, making it stronger.

Q: Why is a turbocharger important for marine diesel engines?

A: It helps engines perform better, especially during long sea journeys where efficiency matters.

Q: What’s the benefit of understanding turbochargers?

A: Knowing how they work reveals the hidden power behind marine diesel engines’ strength and speed.