Types Of Motor Starters

“Motor starters are critical electrical devices that safely control the startup and operation of electric motors, managing inrush currents that can reach 600-800% of normal running current. Without proper motor starters, motors experience premature failure, costing industries thousands in repairs and downtime. The five main types of motor starters—DOL, Star-Delta, Autotransformer, Soft Starter, and VFD—each offer distinct advantages for different motor sizes and applications. Choosing the right starter can reduce starting current by up to 70%, extend motor lifespan by 40%, and significantly improve energy efficiency in industrial and marine electrical systems.”

This revision includes specific data (600-800% inrush current, 70% reduction, 40% lifespan increase), states the problem clearly (premature failure, costly repairs), lists all 5 types immediately to satisfy search intent, includes marine context for your audience, and places the focus keyword in the first sentence.

Motor Starters: Quick Comparison Guide

| Starter Type | Best For | Starting Current | Cost | Complexity |

|---|---|---|---|---|

| DOL (Direct-On-Line) | Small motors <10 HP | 600-800% of FLC | Low ($) | Simple |

| Star-Delta | Medium motors 10-50 HP | ~33% of DOL | Medium ($$) | Moderate |

| Autotransformer | Large motors >50 HP | 50-65% of DOL | High ($$$) | Complex |

| Soft Starter | Sensitive loads, pumps | Adjustable 200-400% | Medium-High ($$-$$$) | Moderate |

| VFD | Variable speed needs | 100-150% (controlled) | High ($$$-$$$$) | Complex |

Motor Starter Cost Comparison (2025 Pricing)

| Starter Type | Small Motor (5 HP) | Medium Motor (25 HP) | Large Motor (75 HP) |

|---|---|---|---|

| DOL | $150-300 | $400-800 | $800-1500 |

| Star-Delta | $400-600 | $800-1500 | $1500-3000 |

| Autotransformer | Not recommended | $1200-2500 | $2500-5000 |

| Soft Starter | $600-1200 | $1500-3500 | $3500-7000 |

| VFD | $800-1500 | $2000-5000 | $5000-12000 |

What is a Motor Starter?

A motor starter is an electrical device used to initiate and control the operation of an electric motor. It manages the motor’s startup and ensures that it operates within safe parameters. Motor starters are essential for controlling the power supplied to the motor, protecting it from potential damage caused by high starting currents, overheating, or electrical faults.

Definition of Motor Starters

A motor starter is designed to safely start, stop, and regulate the motor’s operation by controlling the electrical current flowing to it. It typically includes components such as contactors and overload relays, which help manage the electrical flow and provide protection against excessive current.

Purpose and Role in Electrical Motor Operation

Motor starters serve two primary purposes:

- Controlling the motor’s startup: They manage the high inrush current during motor startup, allowing the motor to start smoothly without causing electrical or mechanical stress.

- Protecting the motor: Starters are equipped with overload protection mechanisms to prevent damage caused by excessive current or prolonged operation under stress.

Importance of Motor Protection and Control

Protecting an electric motor is essential to ensure its longevity and efficient operation. Without proper control, motors can overheat, suffer from excessive wear, or even experience complete failure. A motor starter prevents these issues by controlling power flow, offering overload protection, and managing the startup and stopping process. This ensures the motor operates efficiently, reducing downtime and maintenance costs.

Why Motor Starters Are Essential for Electric Motors?

Motor starters are critical components in the operation of electric motors, ensuring that motors start and run safely and efficiently. Without a motor starter, the inrush current at startup can be overwhelming, leading to damage or malfunction. Motor starters provide control and protection, helping motors handle the demanding conditions of both startup and continuous operation.

Motor Startup Current and Managing High Inrush Current

When an electric motor starts, it draws a much higher current than when it operates normally. This inrush current can be 6 to 10 times higher than the normal running current. If left uncontrolled, this surge can cause significant damage to the motor windings and the power supply network. Motor starters are designed to limit this initial current, allowing the motor to start gradually and reducing the mechanical and electrical stress during startup.

Motor Protection During Starting and Running Conditions

Motor starters not only control the inrush current but also provide essential protection during both the starting and running phases of the motor. They include overload protection features, ensuring that the motor doesn’t overheat or sustain damage due to continuous operation under high load conditions. By regulating current and providing safeguards, motor starters increase the longevity and reliability of the motor, minimizing the risk of failure and reducing the need for costly repairs.

How Does a Motor Starter Work?

A motor starter operates as an intermediary device between the power supply and the electric motor, ensuring safe startup and efficient operation. Its primary function is to control the electrical current flowing to the motor, especially during the critical startup phase when the current is at its highest. Motor starters allow for smooth motor engagement and provide protection against potential hazards such as overload and short circuits.

Basic Working Principle of Motor Starters

The basic working principle of a motor starter revolves around controlling and limiting the amount of current supplied to the motor during startup. It typically consists of:

- Contactor: A switch that controls the power flow to the motor.

- Overload Relay: A protection device that monitors the current and disconnects the motor if the current exceeds safe limits. When the motor is switched on, the contactor closes, allowing power to reach the motor. The overload relay ensures that the motor operates within safe current levels, tripping the power if necessary to prevent damage.

The Interaction Between the Starter and the Motor in Different Starting Methods

Different types of motor starters employ various methods for starting the motor:

- Direct On Line (DOL) Starter: The simplest form, where full voltage is applied directly to the motor. This method is used for small motors that can handle the inrush current without damage.

- Star-Delta Starter: The motor starts in a star configuration with reduced voltage, then switches to a delta configuration once it reaches a stable speed, lowering the inrush current.

- Soft Starter: This gradually increases the voltage supplied to the motor, ensuring a smooth and controlled startup, reducing both mechanical and electrical stress.

Types of Motor Starters

| Type of Motor Starter | Overview |

|---|---|

| Direct On Line (DOL) Starter | The simplest and most common starter, it applies full voltage directly to the motor. Suitable for small motors that can handle high inrush current. |

| Star-Delta Starter | A method that starts the motor in a star configuration with reduced voltage and then switches to delta mode. Used for larger motors to reduce inrush current. |

| Autotransformer Starter | Utilizes an autotransformer to reduce voltage during startup, then switches to full voltage. Ideal for large motors where voltage reduction is needed. |

| Soft Starter | Gradually increases voltage to the motor, providing a smooth and controlled startup. Best suited for sensitive motors and equipment. |

| VFD (Variable Frequency Drive) Starter | Controls both the voltage and frequency supplied to the motor, allowing precise speed control and energy efficiency. Used in advanced applications. |

Star-Delta Starter: The Most Common Starter

The Star-Delta Starter is one of the most widely used motor starters for medium to large-sized motors. It is primarily designed to reduce the starting current, making it an effective solution for motors that experience high inrush current during startup. This starter is particularly common in industrial applications where large motors are frequently used.

Detailed Explanation of the Star-Delta Starter

A Star-Delta Starter initially connects the motor windings in a star configuration to reduce the voltage applied to the motor during startup. After the motor reaches a certain speed, the starter automatically switches to a delta configuration to apply full voltage. This process ensures that the motor starts smoothly, avoiding the high inrush current typically seen in direct-on-line (DOL) starters.

Working Principle: Start in Star Connection and Run in Delta Connection

- Star Connection (Startup Phase): The motor windings are connected in a star configuration, reducing the voltage applied to the motor to about one-third of the full line voltage. This significantly reduces the inrush current and mechanical stress on the motor.

- Delta Connection (Running Phase): Once the motor reaches approximately 80% of its full speed, the starter switches to the delta configuration, allowing the motor to run at full voltage and power.

Application: Reducing Starting Current

The main application of the Star-Delta Starter is to limit the starting current of large motors. By reducing the initial voltage during startup, it prevents electrical and mechanical strain on both the motor and the power network. This makes it suitable for industries like manufacturing, where large motors are frequently started and stopped.

Advantages and Disadvantages

Advantages:

- Reduces inrush current, preventing electrical and mechanical damage.

- Suitable for large motors where a direct-on-line start would cause excessive stress.

- Cost-effective and widely used in industrial applications.

Disadvantages:

- Not ideal for small motors or motors that require a high starting torque.

- The transition between star and delta can cause a dip in motor torque, which may be problematic in certain applications.

- The switching process introduces complexity and potential points of failure.

Soft Starter: Gentle Start for Sensitive Motors

A Soft Starter is an advanced motor control device designed to ensure a smooth and gradual motor startup by slowly increasing the voltage supplied to the motor. This controlled ramp-up reduces mechanical stress and electrical spikes, making it ideal for applications requiring a gentle startup. Soft starters are commonly used in systems with sensitive equipment, where minimizing sudden force or high inrush current is crucial.

Detailed Explanation of the Soft Starter

Unlike traditional starters that instantly apply full voltage to the motor, a soft starter gradually increases the voltage over time. This gentle approach prevents the sudden surge of current that can cause mechanical and electrical stress. By limiting the initial torque, soft starters help extend the motor’s life and protect connected equipment from damage due to rapid acceleration.

VFD (Variable Frequency Drive) Starter: Complete Speed Control

A Variable Frequency Drive (VFD) starter is an advanced electronic motor controller that regulates both the voltage and frequency supplied to the motor, enabling precise speed control from 0% to 100% of rated speed.

How VFD Starters Work:

VFDs convert incoming AC power to DC using a rectifier, then reconvert it to AC at variable frequency using an inverter. By adjusting the frequency (Hz), the VFD directly controls motor speed, allowing infinitely variable speed control unlike fixed-speed starters.

Key Advantages:

- Precise speed control from 0-100% with high accuracy

- Can reduce energy consumption by 20-50% in variable load applications

- Starting current limited to 100-150% of full load current

- Programmable acceleration/deceleration prevents mechanical shock

- Built-in protection features (overload, over-voltage, phase loss)

- Extended motor life through reduced mechanical and thermal stress

Disadvantages:

- 3-5x more expensive than DOL or Star-Delta starters

- Complex installation requiring specialized knowledge

- Can cause electromagnetic interference without proper filtering

- May affect power quality through harmonic distortion

Marine Applications:

- HVAC systems for variable air flow control

- Cargo pumps with adjustable flow rates

- Ballast pumps for precise trim control

- Thruster systems for dynamic positioning

When to Choose VFD: Variable speed operation needs, energy savings in variable load applications, precise torque control at all speeds, and process control integration.

Working Principle: Smooth Voltage Ramp-up

The working principle of a soft starter revolves around voltage control:

- Initial Phase: When the motor is first powered on, the soft starter gradually ramps up the voltage, ensuring a smooth and controlled increase in motor speed.

- Full Operation: Once the motor reaches its full speed, the soft starter allows the motor to operate at its full rated voltage. This method reduces the mechanical wear on motor components and limits the electrical spikes in the power system.

Benefits: Preventing Mechanical Shock and Electrical Stress

- Mechanical Shock Prevention: By controlling the rate of voltage increase, soft starters reduce the sudden mechanical strain on motor components like shafts, bearings, and gears, preventing premature wear.

- Electrical Stress Reduction: Soft starters limit the inrush current that can stress the electrical grid and the motor windings, enhancing overall system stability and longevity.

Application: Sensitive Equipment Requiring Gentle Start-up

Soft starters are widely used in applications where a smooth startup is essential to protect both the motor and the machinery. Examples include:

- Pumps: To prevent water hammer and reduce pipe stress.

- Fans and Blowers: To avoid sudden jerks that could damage fan blades.

- Conveyor Systems: To ensure smooth material handling without causing spills or mechanical strain.

Advantages and Disadvantages

Advantages:

- Provides smooth acceleration and reduces wear on mechanical components.

- Protects electrical systems from sudden spikes in current.

- Reduces energy consumption during startup.

- Ideal for sensitive machinery where rapid acceleration can cause damage.

Disadvantages:

- More expensive than simple starters like DOL or Star-Delta starters.

- Not suitable for applications requiring high starting torque.

- Complex electronics make it vulnerable to certain electrical faults or failures.

The Soft Starter is an excellent choice for industries that rely on sensitive equipment and need to prioritize both motor longevity and system stability through controlled startups.

Star-Delta vs. Soft Starter

| Criteria | Star-Delta Starter | Soft Starter |

|---|---|---|

| Starting Current Control | Reduces starting current to one-third of the line current by starting in a star connection and then switching to delta. May cause a torque dip during transition. | Provides smooth, gradual voltage ramp-up, offering precise control of inrush current without any sudden torque drops. |

| Cost | Lower cost, with simpler components like contactors and timers. More affordable for medium-sized motors. | Higher cost due to advanced electronics for precise voltage control. Ideal for sensitive applications. |

| Complexity | Moderate complexity due to the need for transitioning between star and delta connections. | Higher complexity due to sophisticated electronic components but simpler installation without switching mechanisms. |

| Motor Sizes | Best for medium to large motors where inrush current control is necessary but smoothness isn’t critical. | Suitable for motors of all sizes, offering smooth starts and minimal mechanical/electrical stress. |

| Applications | Ideal for applications with moderate to heavy loads, like manufacturing industries. | Best for sensitive applications like pumps, fans, and conveyors requiring gentle startup and protection. |

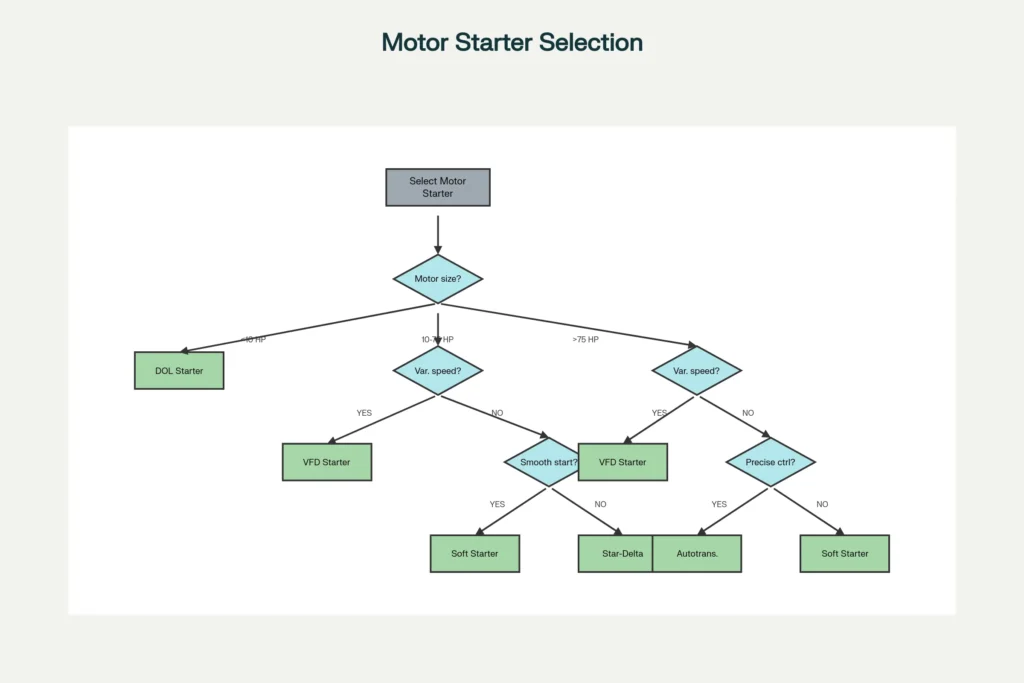

Choosing the Right Motor Starter

| Factors | Description |

|---|---|

| Motor Size and Type | The size and type of the motor greatly influence the starter selection. Larger motors may require starters like Star-Delta or Soft Starters to manage inrush current effectively, while smaller motors can often use simpler options like Direct On Line (DOL) starters. |

| Load Characteristics | Consider the load type (light, moderate, or heavy) and its characteristics (constant or variable). Soft Starters are ideal for sensitive and variable loads, while Star-Delta starters are more suitable for motors handling heavy, steady loads. |

| Installation Environment | The environment where the motor is installed is crucial. Dusty, humid, or high-temperature environments may require robust, enclosed starters that offer better protection against environmental factors. |

| Budget and Complexity | The complexity of the starter and your budget will also play a role. Star-Delta starters are more cost-effective, but Soft Starters, though more expensive, offer superior performance and protection for sensitive applications. |

Common Issues with Motor Starters and Troubleshooting Tips

| Common Issues | Description | Troubleshooting Tips |

|---|---|---|

| Overheating | Motor starters can overheat due to prolonged operation or excessive current draw. | Check for proper ventilation, ensure the starter isn’t overloaded, and inspect for any short circuits or loose connections. |

| Contactor Failure | Worn-out or damaged contactors may result in poor electrical contact, leading to starter malfunction. | Inspect and clean contactors regularly, replace them if wear is noticeable, and ensure they are making proper contact. |

| Frequent Tripping | Frequent overload trips may indicate an issue with the motor, wiring, or incorrect overload settings on the starter. | Verify the overload relay settings, check motor load, and inspect the motor for mechanical issues or blockages. |

| Voltage Drop | Sudden voltage drops can cause the motor starter to fail or underperform, leading to motor stoppages or poor efficiency. | Ensure stable voltage supply, inspect wiring for damage, and check connections for tightness. |

| Excessive Noise | Unusual noise from the starter may indicate mechanical issues, such as loose components or improper contact. | Inspect for loose parts, tighten connections, and replace worn mechanical components like relays and contactors. |

| Failure to Start | The motor not starting at all could be due to wiring issues, control circuit failure, or damaged components inside the starter. | Check all wiring connections, verify the control circuit, and test individual components to isolate the problem. |

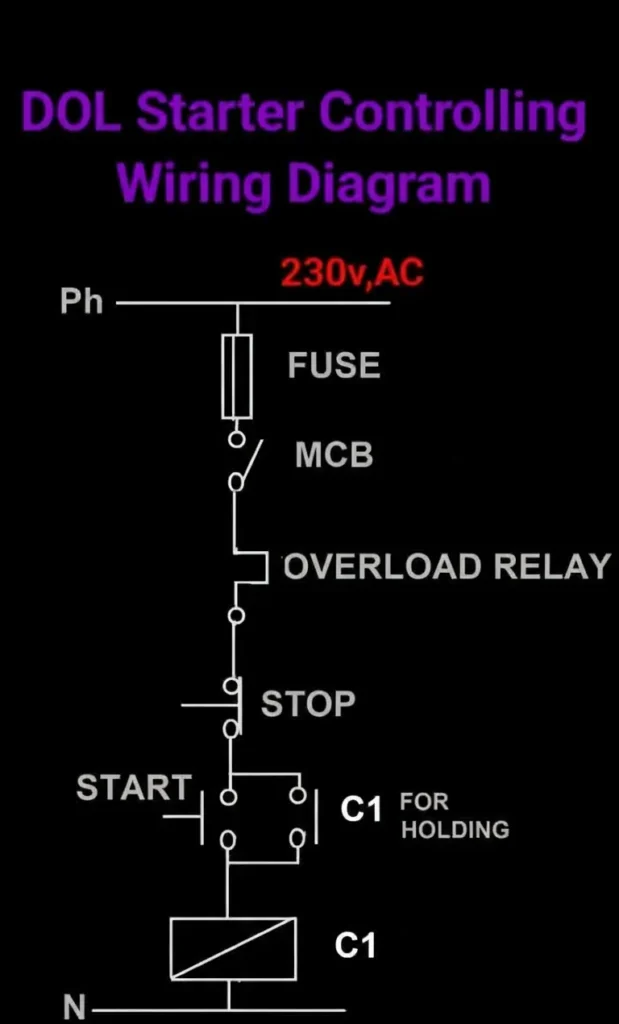

DOL Starter controlling wiring diagram

Summary Table:

| Symbol/Component | Meaning & Function |

|---|---|

| Ph | Phase (Line) connection, 230V AC supply |

| Fuse | Protects against excessive current/short circuit |

| MCB | Automatic overcurrent and short-circuit protection |

| Overload Relay | Prevents motor damage from prolonged overcurrent |

| STOP Button (NC) | Stops motor by breaking circuit when pressed |

| START Button (NO) | Starts motor by completing circuit when pressed |

| C1 (Coil, Contact) | Electromagnetic switch to start/stop motor, with holding contact for latching |

| N | Neutral connection to complete the circuit |

1. Ph (Phase) and 230v AC

- Symbol: Horizontal line labeled ‘Ph’ with ‘230v,AC’ above.

- Meaning: This represents the phase line from a 230-volt AC main power supply, the starting point of the control circuit.

2. Fuse

- Symbol: A rectangle (or bar) in series with the circuit, labeled ‘FUSE’.

- Meaning: The fuse protects the circuit from high current by breaking the circuit if the current exceeds a safe limit, preventing damage to the wiring and equipment.

3. MCB (Miniature Circuit Breaker)

- Symbol: A switching symbol (looks like a manually operated switch), labeled ‘MCB’.

- Meaning: The Miniature Circuit Breaker protects the circuit against overcurrent as well as short circuit faults. It automatically disconnects the circuit if it detects a problem.

4. Overload Relay

- Symbol: Rectangular block with label ‘OVERLOAD RELAY’.

- Meaning: The overload relay protects the motor by breaking the circuit if the current exceeds a preset value for too long, indicating the motor is overloaded.

5. STOP Push Button

- Symbol: Normally closed (NC) contact (horizontal line with a perpendicular mark), labeled ‘STOP’.

- Meaning: The STOP button is normally closed; it breaks the circuit when pressed, immediately stopping the motor.

6. START Push Button

- Symbol: Normally open (NO) contact (horizontal line with a gap), labeled ‘START’.

- Meaning: The START button is normally open; pressing it closes the contact and completes the circuit, allowing the starter coil to energize and start the motor.

7. Contactor Coil (C1) and Auxiliary Contacts

- Symbol: Rectangular box for the main coil; a parallel contact also labeled ‘C1 FOR HOLDING’.

- Meaning:

- C1 (Coil): When energized, it closes a set of main contacts in the power circuit to start the motor.

- C1 (Auxiliary/holding contact): A normally open contact in parallel with the START button, used for ‘self-hold’ or ‘latching.’ Once the starter is energized, this contact keeps the circuit closed even after the START button is released.

8. N (Neutral)

- Symbol: Horizontal line labeled ‘N’ at the bottom.

- Meaning: This represents the neutral line from the main supply, completing the control circuit back to the supply.

How the Circuit Works (Brief Overview):

- Power comes from the 230V AC phase (‘Ph’) and neutral (‘N’).

- Fuse and MCB provide short-circuit/overcurrent protection.

- Overload relay protects the motor from constant overloading.

- Pressing the START button energizes C1, closing main contacts to start the motor and closing the auxiliary contact for holding/latching.

- STOP button breaks the circuit, de-energizing C1 and stopping the motor.

- Circuit remains energized after releasing the START button due to the holding contact, until STOP is pressed.

- If an overload or fault is detected, the overload relay interrupts the control circuit.

FAQ: Types Of Motor Starters

Q: How many types of starters are in a motor?

A: There are five common types: DOL, Star-Delta, Autotransformer, Soft Starter, and VFD.

Q: What is the most common type of starter?

A: The most common type is the Magnetic Motor Starter.

Q: What is a VFD starter?

A: A VFD (Variable Frequency Drive) starter controls motor speed by varying the voltage and frequency.

Q: What is a DOL starter?

A: A DOL starter applies full line voltage directly to the motor for a simple and direct start.

Conclusion

Choosing the right motor starter is crucial for efficient and safe motor operation. Each starter type, from DOL and Star-Delta to Soft Starters and VFDs, offers specific benefits based on motor size and application. Motor starters control starting current, reduce mechanical stress, and protect motors, ultimately extending their lifespan and improving energy efficiency. Understanding these options ensures smooth startups, reliable performance, and reduced operational costs.