Table of Contents

What are the different types of pumps?

Pumps are like special machines that move liquids, like water or chemicals, from one place to another. They work by taking the liquid from low spots and pushing it to high spots, making it go from places with low pressure to places with high pressure. This helps liquids move around easily.

Think of pumps as the hard workers in the world of moving liquids. Pumps do important jobs, like bringing water to our homes and factories, or making sure chemicals flow properly in big machinesWithout pumps, many things we rely on wouldn’t work properly.

There are different kinds of pumps for different jobs. Some are great for sending water far and wide, like in cities, and others are good at carefully measuring and moving small amounts of liquid, like in medicine or making things. Choosing the correct pump is really important because it can make tasks easier and save both time and money.

Centrifugal Pumps

Working Principle

A centrifugal pump works a bit like a spinning whirlpool. Imagine swirling water in a bathtub with your hand – it creates a spinning force. Centrifugal pumps use this spinning force to move liquid from one place to another.

Here’s how it happens: Inside the pump, there’s something that spins the liquid around. This spinning creates more pressure in the liquid, like a push. This extra pressure makes the liquid move to where it’s needed. It’s kind of like when you push a swing to make it go higher.

Centrifugal pumps are super useful in industries because they’re good at moving liquids around efficiently. They help with things like transferring water or other liquids from one spot to another in big machines or factories.

Applications of Centrifugal Pumps: How They Make Life Easier

Centrifugal pumps might sound complex, but they’re like silent helpers that move liquids, making life easier in various ways.

Water Supply: These pumps make sure you have water in your home and cities for drinking, showering, and daily needs.

Irrigation: In farming, they help water fields, ensuring healthy crops and food on our tables.

Wastewater Treatment: When you flush or drain, these pumps help clean up the dirty water before it’s released safely.

Cooling Systems: In cars and factories, they keep things from getting too hot by moving special liquid around.

Oil and Gas Industry: They are very important for pushing oil, gas, and other things through pipes to give power to our homes and factories.

Maritime Industry: On ships, they help balance the ship and deal with seawater for different needs.

Chemical Processing: In chemical factories, they safely move chemicals to make things, ensuring safety and precision.

So, while you may not see them often, centrifugal pumps work behind the scenes, making life more convenient and industries more efficient.

Understanding Positive Displacement Pumps

A positive displacement pump is like a helpful machine that works by trapping a set amount of liquid and pushing it through a system using mechanical power. This process happens over and over in a repeating cycle. What’s neat is that it can use various things like pistons, screws, gears, rollers, or diaphragms to do its job. So, no matter the method, it keeps moving the liquid in a reliable way. Think of it like a little liquid mover that never stops working, and it’s used in many places to transfer liquids efficiently.

Where Positive Displacement Pumps Shine

Positive displacement pumps are like the experts in moving liquids, and they have important jobs in various places where precision matters:

Oil & Gas Industry: They’re crucial for moving oil, gas, and refined products in pipelines accurately.

Chemical Manufacturing: These pumps handle different fluids precisely for making chemicals.

Pharmaceuticals: They’re great at ensuring medicines are made with consistent liquid flow.

Food Processing: From thick sauces to delicate ingredients, they keep food quality high.

Water Treatment: They help measure chemicals like chlorine or fluoride for clean water.

Printing: In big printing, they make sure the ink goes where it should, giving sharp prints.

Automotive Manufacturing: They’re used for painting and lubricating in making cars.

Heavy Machines: These pumps power machines that lift and move heavy stuff on construction sites.

Oil Wells: They help get oil from underground.

Marine Industry: They do various tasks on ships, like controlling weight and cooling.

These pumps are like reliable workers, making sure liquids flow right in many places, and that’s why they’re so important.

Diaphragm Pumps

Diaphragm Pumps: How They Work and What Makes Them Special

Flexibility: Diaphragm pumps are super flexible. They use a rubbery diaphragm, sort of like a stretchy sheet, to move liquids. When this diaphragm bends, it pushes and pulls the liquid, making it go back and forth. This flexibility lets them handle liquids with bits and pieces, like thick slurries, without getting stuck.

Versatility: These pumps can handle many different liquids, from plain water to thick and rough chemicals. This makes them useful in various jobs, like making chemicals or treating wastewater.

Safety: Diaphragm pumps are famous for being safe. They’re really good at handling dangerous or corrosive stuff without letting it spill out, which keeps the workspace safe.

Accuracy: These pumps are great at moving liquids very precisely. They’re perfect for jobs where you need to measure exactly how much liquid is moving, like in making medicines or food.

Reliability: Diaphragm pumps are machines you can count on. These pumps stay in good shape for a while because they’re simple and don’t have many parts that break easily.

So, diaphragm pumps are flexible, versatile, and safe liquid movers that can handle all sorts of fluids with precision and dependability. These pumps are great for handling chemicals and measuring just the right amount of liquid for medicines. They make working with liquids safer and faster in many industries.

Where Diaphragm Pumps Are Really Useful

Diaphragm pumps are like handy tools that are great for many different jobs. They are especially good at handling liquids safely and dependably in various places:

Chemical Industry: These pumps are top choices for moving and measuring different chemicals, even the ones that can be harsh. They’re excellent at keeping everything sealed up tight.

Pharmaceutical Manufacturing: When it comes to making medicines, precision is essential. Diaphragm pumps are experts at delivering the right amount of liquid for medicines.

Food and Beverage Processing: In food factories, they help move things like sauces and syrups, ensuring that the food stays safe and clean.

Wastewater Treatment: Diaphragm pumps are essential for moving thick and muddy wastewater, even when it has bits of solid stuff in it.

Mining and Construction: They help get rid of water in mines and construction sites, keeping things dry and safe.

Oil and Gas Exploration: In drilling for oil and gas, diaphragm pumps handle drilling mud and other liquids to make the process work smoothly.

Agriculture: On farms, they help with things like moving fertilizers and pesticides accurately.

Printing and Packaging: Big printers use diaphragm pumps to put ink in the right place, and packaging machines use them for various jobs.

Marine Industry: On ships, diaphragm pumps help with different tasks like controlling weight and handling sewage.

Water and Environmental Testing: They’re in machines that make sure water and the environment are okay. These machines help gather and test water samples easily.

Submersible Pumps

Submersible Pumps: Why They’re Special

Submersible pumps are like underwater heroes, and they’ve got some amazing features that make them stand out:

Waterproof Wonders: These pumps are built to work underwater, which is perfect for jobs like pumping out flooded areas or drawing water from deep wells. They can go completely underwater without any problems.

Space-saving: Submersible pumps are small and fit nicely into tight spots. You can put them right in the liquid they’re pumping, so you don’t need to do extra work to get them going.

Quiet Operators: They don’t make much noise, thanks to being underwater. This makes them great for homes and places where noise can be a bother.

Efficient and Trustworthy: Submersible pumps work really well and don’t break down easily. They often have safeguards to stop them from getting too hot, which means they last a long time with little upkeep.

Versatile Uses: You can use them in lots of places, from getting rid of water in flooded places to providing water for homes, and farms, and even cleaning up wastewater in treatment plants.

Corrosion Fighters: Many submersible pumps are made to resist corrosion, so they can handle tough jobs like pumping seawater or chemicals.

Easy to Set Up: Installing them is straightforward, and anyone can do it, whether you’re a pro or doing it yourself. No need for complicated setups.

Low Maintenance: These pumps are designed to need very little maintenance. Most of their parts are sealed up to keep out dirt and water.

So, submersible pumps are like champions underwater, with their small size, quiet operation, and efficiency. They’re useful in many places and built to last, making sure water moves where it’s needed without a fuss.

Where Submersible Pumps Are Super Useful

Submersible pumps are like underwater wizards, and they’re used in many different places to do important tasks. Here’s where they work their magic:

Flooded Areas: When places get flooded, submersible pumps come to the rescue. They pump out all the excess water and save the day.

Deep Wells: Getting water from deep underground? Submersible pumps are your go-to. They dive down and bring up the water efficiently.

Quiet Homes: They’re perfect for homes because they’re super quiet. You won’t even know they’re there, making them great for peaceful living.

Tough and Reliable: These pumps are known for being strong and not breaking down easily. They even have special protections to stay cool and last a long time.

All-Around Use: Submersible pumps can do lots of jobs, like providing water for homes, and farms, or cleaning up dirty water in treatment plants.

Handling Tough Stuff: Some of them are made to handle really tough jobs, like pumping seawater or chemicals, thanks to their resistance to corrosion.

Easy Setup: Installing them is a breeze. Whether you’re a pro or doing it yourself, it’s not complicated at all.

Little Upkeep: They’re designed to need very little fixing. Most of their parts are sealed up to keep out dirt and water.

So, submersible pumps are like underwater experts that save the day in many places. They’re quiet, reliable, and do their job without a fuss, making sure water goes where it’s needed.

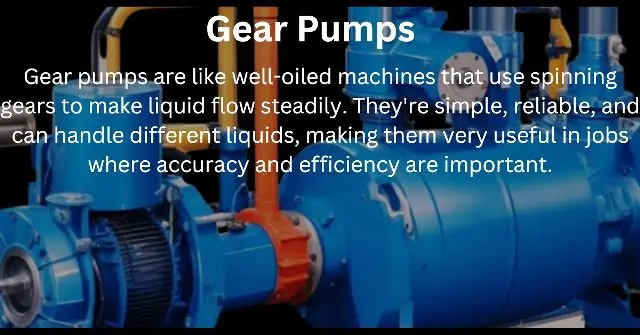

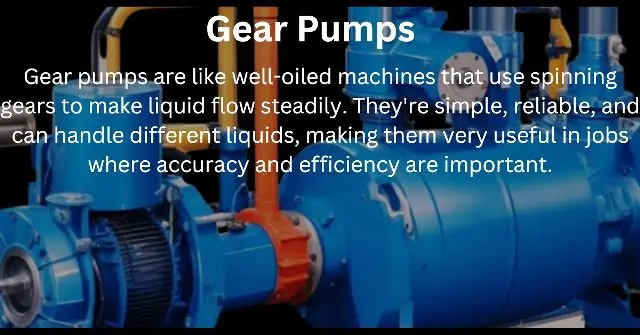

Gear Pumps

How Gear Pumps Work Smoothly

Gear pumps are like the precision experts of pumping, and they have a simple way of getting things done smoothly. Here’s how they do it:

1. Gear Duo: Inside a gear pump, there are two gears—one big and one small—that fit together like puzzle pieces. They spin inside a casing.

2. Liquid In When the gears turn, they pull liquid in through a special opening called the inlet port. The spaces between the gear teeth hold the liquid.

3. Gentle Squeeze: As the gears keep turning, the liquid-filled spaces move towards the exit, called the outlet port. As they move, the gears gently press the liquid, making it pressurized.

4. Steady Flow: The squeezed liquid comes out through the outlet, making a steady flow. The gears fit closely to prevent the liquid from going back, so it keeps moving forward smoothly.

5. Always Reliable: Gear pumps are known for being dependable. They rarely break because they have simple designs with only a few moving parts.

6. Precise Control: These pumps can control how fast the liquid flows very precisely. This is useful in jobs where you need to measure the liquid carefully.

7. Thick Liquids Welcome: Gear pumps are great with thick liquids like oils, syrups, and thick chemicals. They handle them well because of how they work.

8. No Noise: They don’t make much noise because the gears work together smoothly. This makes them a good choice in places where noise is a problem.

In short, gear pumps are like well-oiled machines that use spinning gears to make liquid flow steadily. They’re simple, reliable, and can handle different liquids, making them very useful in jobs where accuracy and efficiency are important.

Where Gear Pumps Come in Handy

Gear pumps are like trusty helpers who find jobs in many places because they’re good at what they do. Here’s where they’re really useful:

- Oil and Fuel Transfer: Gear pumps are perfect for moving oils and fuels, like in cars and machinery. They can handle these fluids smoothly.

- Chemical Plants: In factories that make chemicals, gear pumps help mix and move different substances accurately.

- Food Processing: These pumps are used to move foods like sauces and syrups in the food industry, making sure everything stays clean and precise.

- Pharmaceuticals: In medicine factories, gear pumps play a key role in getting the right amount of liquid for drug production.

- Construction Sites: Gear pumps help with tasks like mixing concrete and other construction jobs, ensuring things go as planned.

- Paper and Printing: Large printers use gear pumps to deliver ink precisely, while paper factories use them to move materials around.

- Marine Industry: On ships, gear pumps are used for various jobs, including handling fuel and ballast control.

- Mining Operations: They help remove water from mining areas, keeping them dry and safe.

- Agriculture: Gear pumps are used in farming to transfer fertilizers, pesticides, and other agricultural liquids.

- Hydraulic Systems: In heavy machinery, gear pumps power hydraulic systems, helping lift and move heavy loads.

So, gear pumps are like versatile helpers that work well in different places. They’re good with liquids, whether it’s fuel, chemicals, or food, and they make sure everything goes smoothly in various industries.

What are 3 types of centrifugal pumps?

Three types of centrifugal pumps are:

- Single-stage centrifugal pump

- Multistage centrifugal pump

- Submersible centrifugal pump

FAQ on ” Types Of Pumps And Their Application”

Q: What are pumps used for?

A: Pumps are used to move liquids from one place to another.

Q: Can pumps handle different types of fluids?

A: Yes, pumps can handle a wide range of fluids, from water to chemicals.

Q: Why is it important to choose the right pump?

A: Choosing the right pump ensures efficient and cost-effective fluid handling.

Q: Where are pumps commonly used?

A: Pumps are commonly used in industries like water supply, chemical manufacturing, and pharmaceuticals, as well as in everyday applications like plumbing and vehicles.

Conclusion: Finding the Perfect Pump

In the end, understanding the world of pumps and where they fit is like having a secret weapon in your work arsenal.

Whether you’re dealing with water supply, chemical manufacturing, pharmaceuticals, or any other liquid-related job, there’s a pump designed to make your life easier.

Selecting the right pump is similar to choosing the correct tool for a task. From handling thick and abrasive fluids to ensuring precise dosing, there’s a pump out there that’s got your back.