Table of Contents

What Are The Types Of Marine Engines

Have you ever found yourself staring at a massive ship, thinking, “What’s giving that beast its oomph?” I sure have. Is it like the engine in your car? Or more like that little motor on Uncle Bob’s fishing boat? 🛥️

Well, strap in. We’re diving deep into the world of marine engines today. Think of it as a tour. From the loud, burly giants to the silent, green heroes – we’re covering the whole spectrum. By the end, you’ll be the one schooling folks at parties! 🎉

Ready to set sail into some engine knowledge? Let’s dive in! 🌊🚢

Two-Stroke Diesel Engines: The Mighty Titans!

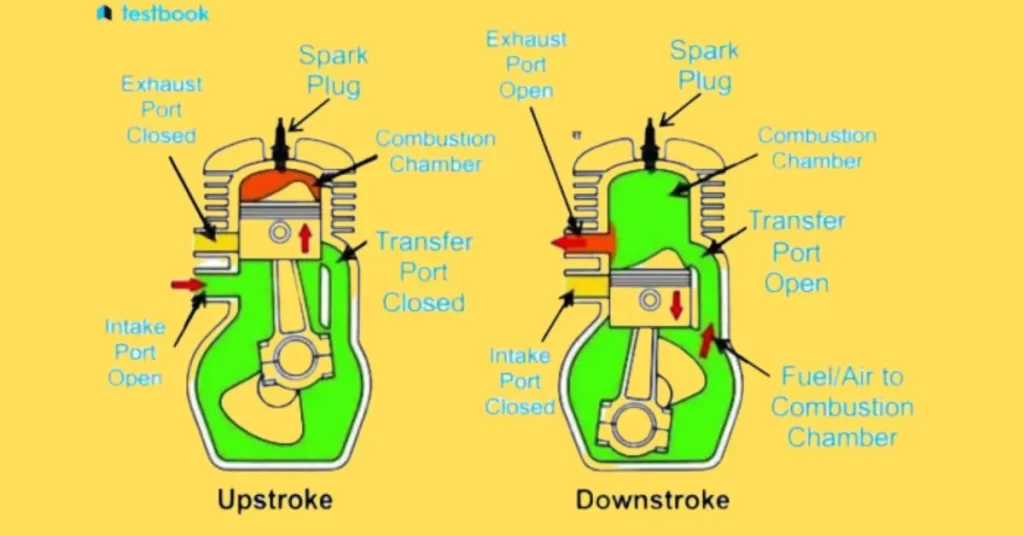

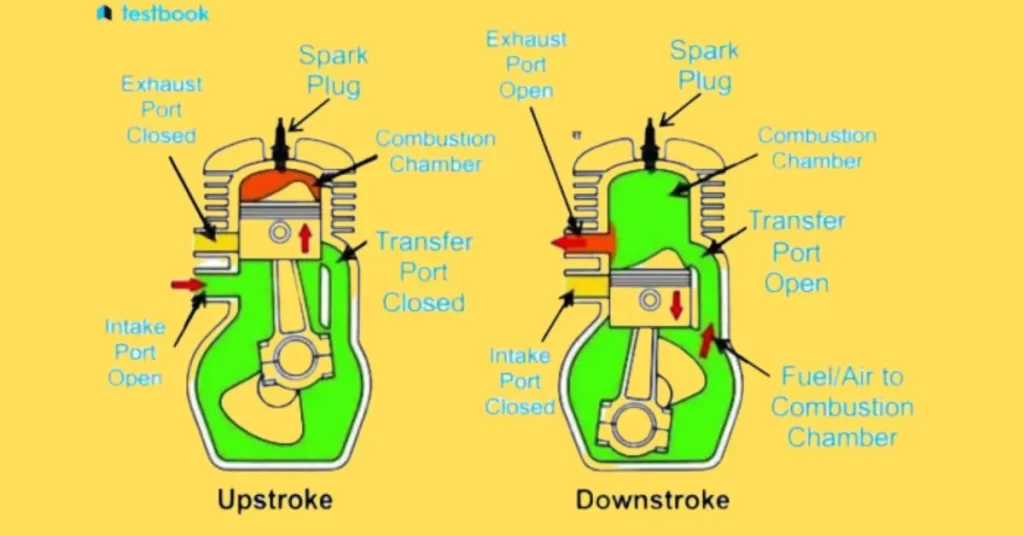

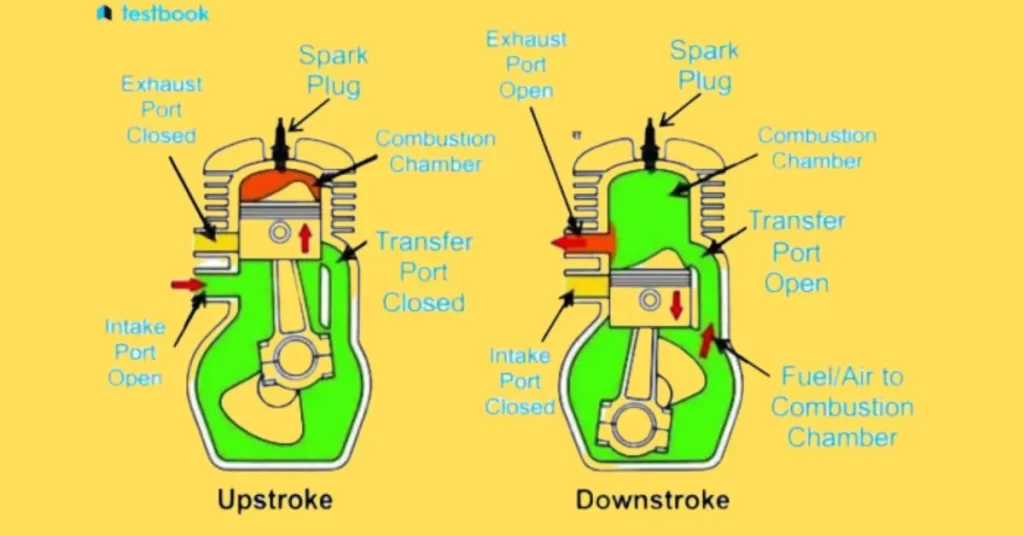

Two-stroke cycle diesel engines rely on an air supply. This air performs two main functions: clearing exhaust gases and refilling the cylinder with clean air. The source of this air is typically a blower or an air compressor, and interestingly, the engine powers this. Depending on their design, these engines can either be of the valve type or the port type. An integral part of their construction is a plate in the crankcase, ensuring air admission. Notably, transfer and exhaust ports are found in the cylinder, and the piston’s movement regulates their exposure: they’re covered when the piston is in one position and uncovered in another.

First Stroke (Upward Stroke of the Piston)

- Compression and Inductance:

- The piston transitions from the Bottom Dead Centre (BDC) to the Top Dead Centre (TDC).

- Both the transfer and exhaust ports remain covered during this phase.

- Previously transferred into the cylinder, the air gets compressed as the piston moves.

- This compression leads to an increase in both the air’s pressure and temperature.

- Concurrently, fresh air gets ushered into the crankcase via the plate valve (often termed the reed valve).

- Ignition and Inductance:

- The piston reaches near the top dead center (TDC).

- Fuel is introduced into the hot, compressed air within the cylinder, leading to a mixture that ignites due to the heat.

- The influx of fresh air into the crankcase persists until the piston fully reaches the top center.

Second Stroke (Downward Stroke of the Piston):- Expansion and Crankcase Compression:

- Burning gases undergo development within the cylinder.

- These gases exert force on the piston, pushing it downward and resulting in useful work.

- Simultaneously, as the piston moves, it compresses the air within the crankcase.

- Throughout this phase, all ports and the plate valve remain closed.

- Exhaust and Transfer:

- As expansion concludes, the exhaust port becomes uncovered.

- The burnt gases find an exit, venturing out into the atmosphere via this exhaust port.

- Shortly after this, the transfer port also reveals itself.

- The crankcase releases its partially compressed air, which enters the cylinder through the transfer port.

- Thanks to the uniquely designed piston, this incoming air is directed upward.

- This upward motion assists in expelling the combustion residues from the cylinder.

- Notably, the plate valve stays closed throughout this phase.

- Expansion and Crankcase Compression:

Four-Stroke Diesel Engines: The Balanced Beauties!

The heart of a vehicle’s engine is the piston. This little part moves up and down inside the engine. When it goes up, there’s more space in the engine’s “combustion chamber.” When it goes down, there’s less space. This changing space helps the diesel engine run.

So, what’s this “4-step cycle” about?

A 4-stroke diesel engine has four main actions happening in one full cycle. For every action, the piston moves once. So, in this 4-step cycle, the piston goes up and down twice each.

To understand this, know these main parts:

- Cylinder block: It’s like a track where the piston moves.

- Piston: A tube-like part that slides up and down in the cylinder block.

- Cylinder head: It’s the top cover of the cylinder. It also holds parts like injectors and valves.

- Injector: This squirts diesel fuel into the combustion chamber with force.

- Connecting rod & crankshaft: They turn the piston’s up-and-down motion into a round-and-round one.

Suction Step (or Intake Stroke)

Think of the suction step as the engine taking a deep breath. When the piston moves from its highest point (TDC) to its lowest point (BDC), it creates more space inside the engine.

While this happens, a special door called the “inlet valve” opens. This lets the engine pull outside air from the “intake manifold.” The air then fills up the space inside the engine.

Compression Steps Explained

- What’s happening? After the engine takes in the air (suction step), it squishes this air tightly inside its cylinder.

- Why compress the air? Diesel engines don’t use spark plugs to start the burning process like some other engines. Instead, they rely on air getting super hot by being compressed. This heat can light up diesel fuel, called “self-combustion.”

- How does it work? Once the piston finishes the suction step at its lowest point (BDC), it returns to its highest point (TDC). This upward movement squashes the air inside. The intake and exhaust doors (or valves) stay shut during this, ensuring the air is trapped and compressed.

Combustion Step Explained

- What happens? This step is where the magic happens! Diesel is squirted into the engine’s hot, compressed air.

- Why does it burn? Remember when we said the air gets super hot from being squished? When the piston reaches its top spot (TDC), the air is hotter than diesel’s burning point. So, when diesel is added, it catches fire instantly.

- What does this do? The burning creates a powerful burst, like a mini explosion. This force pushes the piston back down. This powerful push is what drives vehicles and makes them go!

Exhaust Step Explained

- What’s Going On? After the mini-explosion from the combustion step, the engine has leftover gases. We need to expel them out.

- How Do We Do That? When the piston starts moving back up, an exhaust valve opens. The rising piston pushes these old gases out through this valve, cleaning up the chamber.

- Wrap-Up: By the end of this exhaust step, we’ve had 4 main actions:

- Suction: The piston goes down, pulling in air.

- Compression: The piston goes up, squishing the air.

- Burning: Diesel’s added, causing a mini explosion, pushing the piston down.

- Exhaust: The piston goes up, pushing out old gases.

So, we get one of these mini-explosions every two full spins of the engine’s crankshaft.

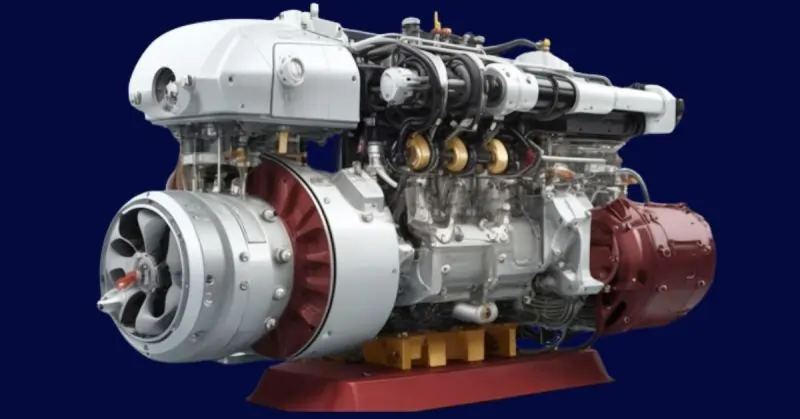

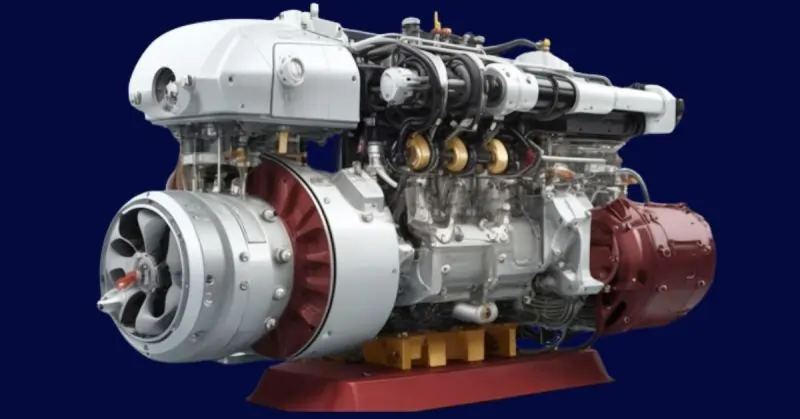

Gas Turbine Engines: The Speed Demons!

Marine Propulsion Simplified

In the world of marine propulsion, gas turbine engines have emerged as a promising alternative to traditional steam and diesel engines. One of the main reasons ships are considering gas turbines is their lightweight design and compact size. This allows ships to be more efficient and agile on water. The American Navy recognized the potential of gas turbines in the 1970s. To test it, they mounted a strong gas turbine of 20,000 horsepower aboard a ship.

The ship performed exceptionally well during its test phase, running seamlessly for over 5,000 hours on the open sea. This significant achievement proved the reliability and efficiency of gas turbines in maritime settings. As a result, seeing the apparent benefits, the U.S. Navy decided to implement gas turbines in designing and constructing several new naval vessels, marking a shift in maritime engineering and design.

What’s a Gas-Turbine Engine?

Think of it as an engine that uses gas to spin a turbine, like a big fan inside. This engine isn’t just the turbine; it also has parts to squeeze air (compressor), burn fuel (combustion chamber), and more.

What’s Cool About It?

- Doing Work: This engine can do different jobs. It can generate electricity, move water, push ships, or even make planes fly.

- Size & Power: They’re strong! For their size, they give out a lot of power. So, they’re like tiny but mighty superheroes.

- Direct Power: Unlike some engines that move up and down (like the ones in cars) and need extra parts to turn that motion into spin, these engines spin things directly.

- Challenges: Even though the idea sounds simple, making it is challenging. They need unique designs and expensive stuff because they work super hot and fast. So, I usually see them in big setups where they’re worth the cost.

Gas-Turbine Engine Parts Explained

Compressor:

- Think of this as the engine’s big fan that squeezes air.

- Older models used simpler, cheaper fans but were less effective than the newer axial-flow compressors.

- These newer compressors work like reversed turbines, with specially shaped blades to manage the air.

- Air gets more and more squeezed as it moves through several stages.

- Getting the right balance and avoiding problems (like stalling) in this part is tricky.

Combustion Chamber:

- After the air is squeezed, it slows down and splits into two streams.

- The smaller stream mixes with fuel and burns. The bigger, cooler stream helps manage temperature.

- The burning can happen in different arrangements, either in separate ‘cans’ or a single looped space.

Turbine:

- Hot gases from the combustion chamber spin the turbine.

- This turbine can have several stages and can drive other parts of the engine or external loads.

- The materials and design here have to handle super-hot temperatures. Some blades even have special cooling techniques.

Control and Start-Up:

- Engine speed has to be kept steady, especially when driving something like an electric generator.

- For airplanes, controlling the engine is more complex because of changing conditions in the air. Computers help manage this.

- You need an external power source, like an electric or diesel motor, to start the engine.

Other Things to Consider:

- The engine has bearings that help things spin smoothly.

- When the engine heats up, parts can change shape and size, affecting how things fit together.

- Some designs take air from the compressor for different uses, like cooling or driving other small parts.

Steam Turbine Engines: Nostalgia Meets Power!

Steam Turbines

Steam turbines are like giant windmills inside a case. Steam hits blades, making them turn. This motion is used for power. They’re compact but powerful, so they’re great for generating electricity and moving big ships. Some can produce over 1.3 million kilowatts on one shaft!

Types & Categories

- Impulse vs. Reaction: Turbines are sometimes classified by how they turn. Some use direct steam force, while others use steam’s reaction. Some even combine both ways.

- Condensing vs. Noncondensing: There are two main types based on how steam is used.

- Condensing turbines turn steam back into water to get more energy. They need a lot of cooling water. They’re very efficient and are used in big power plants.

- Noncondensing turbines let steam out at high pressure. This steam is used for other things, like heating, before turning back into water.

- Steam Extraction: Some turbines take out a bit of steam in the middle. This can help heat water going back to the boiler. There are three types:

- Straight-through (no extraction)

- Bleeder or extraction (no pressure control)

- Controlled extraction (controlled steam removal)

- Reheat vs. Nonreheat: Some turbines reheat steam for better efficiency. Big electric stations might reheat twice. Small places use nonreheat turbines.

- Flow & Arrangement: High-pressure steam can expand a lot. To manage this, some giant turbines divide the steam into many paths. Some turbines are on one shaft, others on two shafts.

Main Parts

- Rotor: The moving part with blades. It turns when steam hits it.

- Casing: The outer shell. It holds the steam and has fixed parts for directing steam.

- Speed Control: This controls how fast the turbine spins.

- Support System: This has bearings for the rotor and oil for lubrication.

Electric Engines: The Silent Revolutionaries!

Electric marine propulsion is an intelligent choice for the future. With the shipping world changing so much, you need an adaptable system. This kind of propulsion gives you the ability to change without stress, especially when it comes to future fuel types and costs. This electric system offers flexibility if you’re unsure what other power sources complement your engines. It’s also great if you need clarification about your ship’s future operations.

Traditional diesel-electric systems are highly adaptable. One key feature is that the power generators (gensets) are only linked electrically to the propulsion system. This design means you can easily swap them out for newer power sources later on, like engines using new fuels, batteries, or fuel cells.

Advantages of Electric Marine Propulsion

- Better for the Environment: Electric propulsion systems are cleaner even if you use diesel generators. They work efficiently, reducing harmful emissions like NOx/NO, CO, CO2, and soot.

- Fuel Saver: You can use only the necessary generators when the propeller goes slow. This means engines work better and use less fuel.

- Quiet Ride: Electric propulsion is quieter, with less noise and vibration.

- More Trustworthy: The system can be set up with backups, making it more dependable.

- Flexible Operations: The motor’s power can adjust quickly, letting the propeller work within its design limits without problems.

- Better Control: Electric systems are great for precise movements and quick speed changes, making it easier to navigate and position the ship.

- Clean Energy Supply: The system only messes with the ship’s main power, ensuring fewer disturbances or voltage issues.

- Simple to Use: Ship controllers can automatically and hand-handle electric propulsion systems. They have monitoring features to avoid mistakes and prevent overworking.

- Cost-effective: An electric system means fewer diesel engines. Since motors maintain a steady speed, there’s less wear and tear. This leads to cheaper maintenance and fewer replacement parts, saving money in the long run.

How does an electric engine work?

An electric engine, or motor, uses power from a battery. The battery has DC power, but the motor needs AC power. So, we use a device to change DC to AC. When you press the car’s pedal, it tells a controller how fast you want to go. The controller adjusts the AC power’s speed sent to the motor. Then, the engine uses a gear, or cog, to turn the wheels and move the car. In short, the battery gives power, the pedal tells the car how fast to go, and the motor turns the wheels. It’s a smooth system that makes driving electric vehicles easy and efficient.!

Blog Conclusion

Navigating the world of marine engines can feel like charting unknown waters. The choices seem endless, from two-stroke to four-stroke, from diesel to outboards. The engine type, like picking the right boat for a leisurely lake day versus deep-sea fishing, also matters.

For instance, think of diesel engines as reliable workhorses. They’re like your sturdy, old friend who’s always got your back during long journeys. On the other hand, outboards? They remind me of those zippy scooters on city streets – quick, easy, and perfect for short trips.

But, hey, that’s just my take on it. What’s yours? Which engine type revs up your maritime dreams? Drop a comment, share your thoughts, or throw in some questions. Let’s navigate these waters together!

FAQ on ” What Are The Types Of Marine Engines”

Q: What are the primary types of marine engines?

A: Diesel, outboard, inboard, and sterndrive are the main marine engine types.

Q: Which engine type is common for long journeys?

A: Diesel engines are favored for their reliability on longer trips.

Q: Are outboard engines suitable for large vessels?

A: Outboards are typically used for smaller boats and short trips.

Q: What’s the difference between inboard and sterndrive?

A: Inboards are fixed inside the boat, while sterndrives combine inboard and outboard features.