What Is Crankcase Explosion

In this article, we will discuss the Crankcase explosion. A crankcase explosion is a serious threat to the ship’s safety and may be fatal to human beings. Crankcase explosion takes place in two stages known as primary and secondary occurring in the Engine Crankcase.

Crankcase explosion is the greatest and most severe threat to the safety of Ships and is fatal to human beings working in close vicinity. This phenomenon occurs due to the oil mist in the crankcase getting ignited after coming into contact with any hot spot. A hot spot can be due to various reasons like poor maintenance of the Engine, and neglected maintenance schedule of the Engine. If the primary explosion is not taken then, the secondary explosion takes place

A crankcase explosion is when the engine’s crankcase explodes because of an oil mist catching fire. An engine’s crankcase has what it needs for an explosion. To understand it, think of the fire triangle.

Three Essential Elements of Fire

To have a fire or explosion, you need three things: heat, fuel, and oxygen. These three make the fire triangle. But for a fire to start, oxygen and fuel must be in the correct ratio. If there’s too much oxygen (lean) or too much fuel (rich), it won’t ignite.

So, even though an engine’s crankcase always has these three things, an explosion happens only when the air-fuel ratio is right. Let’s see how a crankcase explosion happens step by step.

The fire triangle consists of three essential elements. These three elements are Oxygen, Heat, and fuel. The presence of these three elements in proportionate, will cause the fire and subsequently result in a crankcase explosion.

In the Engine’s crankcase, the oil travels in the vapor form of tiny particles of 200 microns. These small particles can never ignite in the presence of even naked flame. Accidentally due to any hot spot in the crankcase, these particles will be reduced and form the mist. This mist will get easily ignited once in contact with the hotspot.

If there are multiple hot spots, then the density of the mist will increase in Geometric progression. This movement, once the mist is ignited, will result in the primary explosion. If the created pressure is not relieved during this period, this will rupture crankcase doors and relief valves. The low pressure will suck in the fresh air from the damaged parts and leaky crankcase relief valves. Another phenomenon is serious, which will cause a significant explosion.

Steps to Take for Small Fires

- Reduce the Engine Speed.

- Cut off the fuel supply of the particular unit.

- Don’t increase the cylinder lubrication, In case the fire is more

- Maintain the cooling flow through the Jacket and piston

- Shut the scavenge drain cock.

- Cut off the Fuel injection pump of the affected unit.

- Monitor the exhaust and scavenge temperatures

Steps to Take for Major Fire

- Stop the engine immediately

- Engage the turning gear and start turning the engine to prevent the seizure of significant components.

- Attempt to extinguish the fire with the fixed fire fighting system or the

- Open and inspect the scavenge space after proper cooling down once it is confirmed that the fire is extinguished.

What is a Hot Spot?

The hot spot is the heat source produced due to the rubbing of metal surfaces such as Piston rods and glands, crosshead guides, and Bearings getting overheated due to oil starvation, or excessive blow-by in the crankcase. The hot spot will be termed only if the spot’s temperature is more than the ignition point of the fuel. The hotspot temperature in the crankcase is in the range of 200 to 400 Degrees C.

Hotspots are generally the result of poor maintenance and improper clearances between the moving parts.

When the oil comes in, the contact of hot spots will get converted into vapors. These vapors traveling towards the colder surface will form a white mist. Over a period, the density of this mist will keep on increasing due to repeated contact with the hot spot. The extent of an explosion will depend upon the amount of mist produced.

Causes of Hot Spots

- Abnormal Engine operation with obnoxious noise.

- The alarm on Oil mist detector.

- High Lubricating oil temperature.

- Dense smoke from crankcase breather.

- High exhaust temperature with sudden surging.

What is Blow-past/ Blow-by

Blowy is the exhaust gases leaking from the combustion chamber to the Crankcase through poor sealing between the Piston rings and cylinder liner

The effect of the blowy

- In a two-stroke engine, blow-by will enter into the scavenge post and cause heavy fouling. Accumulation of these particles of carbon will lead in to scavenging fire.

- The blowy will enter into the Crankcase in the four-stroke Engine, causing the hot spot and serious crankcase explosion.

Causes of blow-by/blow-past

- Excessive worn-out piston rings or damaged piston rings

- Lubricating oil starvation

- Inferior quality of oil or oil not meeting the OEM specifications.

- Piston ring grooves fouled with carbon deposits.

- Poorly maintained piston rings butt and axial clearances.

- The cylinder liner is worn out more than the specified limits.

- Overloading of the Engine.

Prevention of Blow by or Blow past

- During maintenance, replace all the piston rings with excessive clearances.

- Carry out the gauging of the cylinder liner bore. Carry out honing, and after honing if the dimensions are more than the specified limits, replace the liners.

- Use the recommended grade of lubricating oil and maintain the proper lubrication.

- Prevent overloading of Engine.

Preventing Crankcase Explosions

- Avoiding the high temperature of the parts by providing the appropriate lubrication.

- Engine not to be overloaded.

- Using proper bearing with proper material composition.

- Use of oil mist detector

- Crankcase doors with pressure relief valves.

- Periodical testing of crankcase pressure relief valves.

- Check the vent pipe for any choking etc.

- Proper standby fire extinguishing system

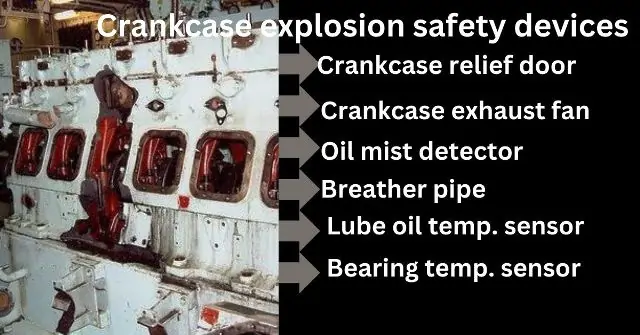

Crankcase Safety Devices

- Crankcase relief door.

- Crankcase exhaust fan

- Bearing temperature sensor

- Breather pipe

- Oil mist detector

- Sensors for the Lube oil temperature.

- Alarm for the Lube oil temperature.

All the above-listed devices play an essential role in the safety protection of crankcase explosions. Out of the above devices, the Mist detector and crankcase relief door play a significant role in preventing the crankcase explosion.

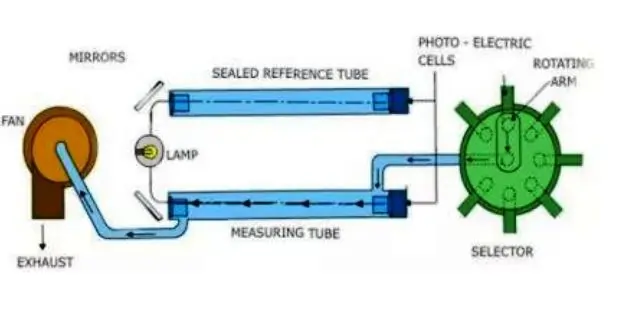

Oil Mist Detector

Marine Diesel is provided with an essential instrument toMarine Diesel Engine is provided with an essential instrument to detect the level of mist in the crankcase. The function of this device is to check and monitor the mist in the crankcase.

This device can identify the mist within its ignitable territory. An oil mist detector consists of flowing parts

- A sampling Point

- Reference tube

- Extraction fan

- Light source

- Measuring tube

- Rotary vane

Reference and mist detector consists of reference and measuring tube as the elements. The light source is detected through mirrors to the cell placed on the opposite side of the tubes. Fresh air is filled in the reference tube, and the measuring tube is connected to the sampling point for the sample to be tested. The sample air is induced into these tubes through the sampling points with the help of a suction fan.

The rotary vane then shifts between the sampling points at fixed intervals. This process allows the detection of mist in other cylinders using a mono-oil mist detector.

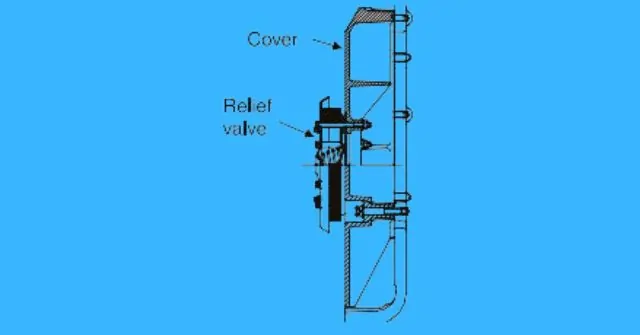

Crankcase Relief Valves

The crankcase relief valve is the spring-loaded non-return valve fitted on the crankcase doors. It discharges any sudden increase in the crankcase pressure during the primary explosion state. Being a relief valve, its operation is only one way that is from inside to outside. The spring fitted in the valve ensures instant closer of the valve after the release of gas. The number of valves per engine is decided by the classification societies to prevent Explosion And Fire In Marine Engines.

Crankcase exhaust fan

A crankcase exhaust fan is a device that takes away bad gases from the inside of an engine or machine. A crankcase exhaust fan is like a protector for diesel engines. It makes sure that where people work stays safe and healthy by taking out harmful gases, like carbon monoxide, from the engine’s belly.

This is very important in locations where machines with diesel engines are used, like factories or generators fans are like protectors that make sure dangerous gases don’t stay inside and hurt people or damage the engine. They work by making air move, so the bad stuff gets pushed out, either outside or into a special system.

A crankcase exhaust fan is like a protector for diesel engines. It makes sure that where people work stays safe and healthy by taking out harmful gases, like carbon monoxide, from the engine’s belly.

This is very important in locations where machines with diesel engines are used, like factories or generators.

Breather pipe

A breather pipe is a clever way to stop too much pressure from building up inside the engine’s belly. It’s like a safety valve. This pipe often has a special trap to stop fires from spreading to other places.

Imagine your engine is like a big container, and sometimes it makes extra air or pressure inside. A very high crankcase pressure can be dangerous. But with a breather pipe, it’s like having a window to let out the extra pressure safely.

Think of the flame trap as a strong shield that acts like a superhero, making sure that if there’s a fire inside the engine, it can’t get out and cause problems in other places.

This is really helpful because it keeps the engine and the place around it safe, so everything works smoothly and without danger.

Sensors for the Lube oil temperature

Lube oil temperature sensors are like little detectors in the engine. They’re good at telling us if the oil inside the engine is getting too hot. When the oil gets hotter than it should, it can be a sign that something is wrong with the engine, like a spot that’s getting too hot.

Imagine you have a thermometer for your body when you’re sick. It tells you if you have a fever. Well, these sensors are like fever detectors for the engine. They let us know if the engine is getting a “fever” or getting too hot in certain places.

Knowing this helps us catch problems early and keep the engine running smoothly. It’s like having a warning system to make sure everything is okay inside the engine.

Alarm for the Lube oil temperature

An alarm for lube oil temperature is like a safety bell for engines. Sometimes, it’s a good idea to also have sensors for bearing temperature. These sensors work like bodyguards for the engine, making sure everything is safe.

Imagine you have a fire alarm in your house. It goes off if there’s smoke or a fire. Well, these alarms are like that but for engines. They can tell if something is getting too hot, like when a bearing is having a problem. If a bearing gets too hot, it can create a dangerous spot in the engine, and in rare cases, it might even lead to an explosion.

So, these alarms are like superheroes, always on the lookout for signs of trouble and making sure the engine stays safe and sound.

Signs of Crankcase Explosions Without Using Instruments

- Touch or use an infrared thermometer to check for hot spots.

- Listen for irregular engine running.

- Pay attention to abnormal sounds or vibrations in the main engine.

- Look for the appearance of thick white mist or the smell of it coming from breather pipes or drain cocks.

Signs of Crankcase Explosions Using Instruments

- Bearing lube oil temperature goes up.

- Bearing temperature increases.

- The oil mist detector alarm goes off.

- A crankcase relief valve operates, and you see smoke, sparks, or oil.

Blog Conclusion

In the world of engines, there’s something important we need to talk about – crankcase explosions. These explosions can be really dangerous, but many people don’t know much about them. It turns out that things like mixtures that can catch fire and not taking care of engines properly can cause these explosions. They’re not just bad for machines; they can hurt people and cost a lot of money too. But don’t worry, knowing about these explosions can help us stay safe. Let’s remember to be careful and ready, so these scary explosions become something that hardly ever happens anymore.

Best Books on Marine Engineering

Fundamentals of Medium/Heavy-Duty Diesel Engines

Based on the 2014 National Automotive Technicians Education Foundation (NATEF) Medium/Heavy Truck Tasks Lists and ASE Certification Test Series for truck and bus specialists, Fundamentals of Medium/Heavy Duty Diesel Engines is designed to address these and other international training standards. The text offers comprehensive coverage of every NATEF task with clarity and precision in a concise format that ensures student comprehension and encourages critical thinking. Fundamentals of Medium/Heavy Duty Diesel Engines describes safe and effective diagnostic, repair, and maintenance procedures for today’s medium and heavy vehicle diesel engines, including the most current, relevant, and practical coverage of • HD-OBD emission diagnostics • Common rail injection systems

Pounder’s Marine Diesel Engines and Gas Turbines

Pounder’s Marine Diesel Engines has served seagoing engineers, students of the Certificates of Competency examinations, and the marine engineering industry throughout the world.

Now in its ninth edition, Pounder’s retains the directness of approach and attention to essential detail that characterized its predecessors. There are new chapters on monitoring control and HiMSEN engines as well as information on developments in electronic-controlled fuel injection. It is fully updated to cover new legislation including that on emissions and provides details on enhancing overall efficiency and cutting CO2 emissions.

After experience as a seagoing engineer with the British India Steam Navigation Company, Doug Woodyard held editorial positions with the Institution of Mechanical Engineers and the Institute of Marine Engineer

- Helps engineers to understand the latest changes to marine diesel engineers

- Careful organization of the new edition enables readers to access the information they require

- Brand new chapters focus on monitoring control systems and HiMSEN engines.

- Over 270 high-quality, clearly labeled illustrations and figures to aid understanding and help engineers quickly identify what they need to know.

Lamb’s Questions and Answers on the Marine Diesel Engine

Nearly every aspect of marine diesel engines is covered in the book.

Additionally, it describes air tanks, compressors, balancing, instruments, controls, and safety in addition to engine parts. The book is called “Lamb’s Questions and Answers on the Marine Diesel Engine.” It was published in 1990 by Butterworth-Heinemann. The latest edition is the eighth, and it comes in hardcover.

A Pocket Book of Marine Engineering: Questions and Answers

Engine air filters are covered in depth in the book “A Pocket Book of Marine Engineering: Questions and Answers”. The person who wrote this book is an expert in Marine Engineering. He explains in detail the workings of engines and how to pick filters. Basics like steering, safety, engines, and many more marine engineering topics are in the scope of this book.

Diesel Generator Handbook

Diesel Generator Handbook meets the need for an authoritative reference work covering the range of mechanical and electrical topics embodied in the practical design and application of diesel-generating plants. It will be particularly welcomed in many parts of the developing world where the diesel generator is basic to the electricity supply system.

The discussion covers, in fifteen chapters, the prime mover, power ratings, synchronous generators, load assessment, control principles and systems, switchgear and control gear, standby power, fuels and lubricating oils, installation and commissioning, noise reduction, plant operation and maintenance.

The book thus caters to all who are concerned with the selection, specification, testing, commissioning, operation, and maintenance of diesel-based generator systems: not only the practicing plant or services engineers but also non-specialist engineers and users. The young technician or trainee engineer who is embarking on a career in the supply industry will find this handbook an invaluable investment.

L L J Mahon, FIEE, FBIM, after an engineering apprenticeship with BTH in Rugby, gained over 30 years of experience in the design, development, manufacture, installation, and commissioning of both stationary and highly specialized mobile diesel generator plants for a range of applications.

FAQ on ” What Is Crankcase Explosion”

Q: What is a crankcase explosion?

A: A crankcase explosion is a sudden burst of flames and pressure inside an engine’s crankcase.

Q: What causes crankcase explosions?

A: Crankcase explosions are caused by a mix of fuel and air igniting within the engine’s enclosed space.

Q: Why are crankcase explosions dangerous?

A: Crankcase explosions can damage the engine, endanger people nearby, and lead to costly repairs.

Q: How can crankcase explosions be prevented?

A: Regular maintenance, proper ventilation, and the use of safety devices can help prevent crankcase explosions.