Table of Contents

Marine Chief Engineer Interview

Embarking on a journey into the world of marine engineering? Get ready for success with the “Marine Chief Engineer Interview: Best 20 Q and A.” Here, we’ll dive into the top 20 questions and answers to help you prepare and excel in your marine chief engineer interview. Let’s discover tips that help you stand out and leave a strong impression in your interview.

The Marine Chief Engineer Role

The key role of the Marine Chief Engineer is to manage the ship’s mechanical and Technical systems. They’re like the captain of the engineering team, making sure the ship’s machinery works smoothly. A chief marine Engineer takes care of breakdowns, safety checks, and the smooth running of the ship. In addition to the administerial duties they keep a close watch on the Engines, find out the operational problems and ensure the smooth running of all equipment.

They coordinate with other teams for the planning of the budget and fulfill the requirements needed. With their expertise and skills. they ensure the safety of the ship and comply with the rules. This job needs lots of technical knowledge, fixing skills, and being a good leader. They really understand how ship engines and systems work to keep things sailing smoothly.

Preparing for a Chief Marine Engineer Interview

Q1:What is your hands-on experience in the operation and maintenance of marine propulsion systems?”

Ans: Garnering a solid ten years in the Marine Engineering sector, my expertise is honed in operating and preserving a wide range of marine propulsion systems. I’ve worked with diesel, gas turbine, and nuclear power plants, getting my hands dirty. I also know a lot about handling navigation, communication, and safety stuff. When things go wrong, I’m good at fixing them quickly. This helps the ship work well and stay safe all the time.

Q2:Can you explain your strategy for dealing with complicated mechanical problems?

Ans: When faced with intricate mechanical complications on a ship, my priority is always safety. I ensure everyone understands their roles in line with safety regulations, and I conduct regular engine room inspections to anticipate and mitigate any potential risks. Upon identifying a problem, I promptly evaluate the situation and devise an effective solution. Moreover, I always report breaches in safety regulations for timely resolution and continuous safety assurance.

Q3:What Measures Do You Take to Ensure Safety Protocols in the Engine Room?

Ans: As a stickler for safety protocols in an engine room, I prioritize informing all staff about the rules, standards, and their significance. As a chief engineer, I conduct routine inspections for possible hazards. Moreover, I stress the importance of comprehensive training on safety measures and the ramifications of non-compliance. Emphasizing prompt reporting of any breaches or risks, I ensure quick resolutions.

Q4:How Do You Apply SOLAS Regulations in Your Marine Engineering Role?

Ans: With a solid understanding of the International Convention for the Safety of Life at Sea (SOLAS) regulations, I prioritize safety in all marine operations. These worldwide rules say we have to do important things to stay safe. They cover stuff like stopping fires, having life-saving gear, and making sure our navigation and communication systems work well. As a Marine Chief Engineer, I’ve actively enforced these regulations, ensuring all relevant equipment is well-maintained and fully operational. Regular vessel inspections for SOLAS compliance are a standard part of my role, allowing me to continually uphold safety as the cornerstone of my duties.

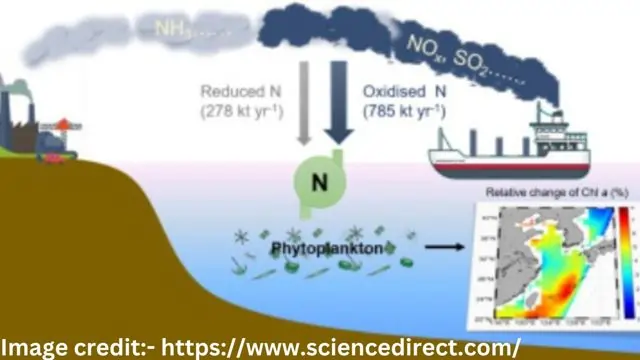

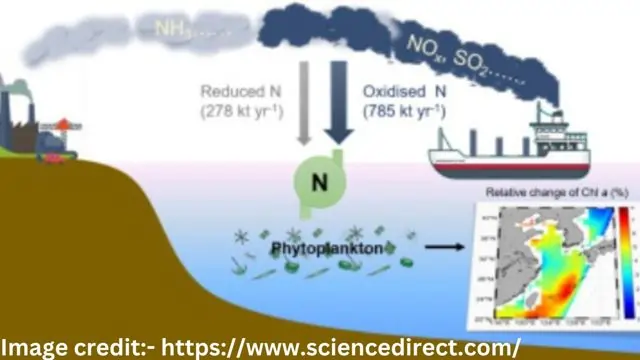

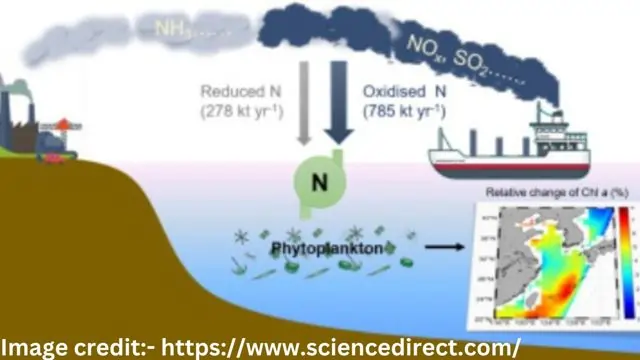

Q5:Are you updated with the most recent environmental regulations that pertain to the field of marine engineering?”

Ans: Indeed, I am acquainted with the most recent environmental regulations connected to marine engineering. My experience spans local, federal, and industry-specific guidelines. Having received extensive safety training on these regulations, I also hold certifications in managing hazardous materials and wastewater disposal. In past engagements, I have effectively incorporated various regulatory best practices to meet all safety standards meticulously.

Q6:How Do You Optimize Fuel Efficiency During Vessel Operations?

Ans: My approach to ensuring fuel efficiency involves a multi-pronged strategy. Primarily, I concentrate on optimizing engine performance, adjusting engine parameters to reach peak efficiency. I also diligently manage trim levels and employ slow steaming techniques where viable. I am vigilant about identifying and rectifying any air leaks in the engine room and religiously follow a preventative maintenance schedule to maintain the ship’s optimal operation. Importantly, I always stay abreast of innovative ideas and technological advancements that can boost fuel efficiency.

Q7-Can you share your experience leading a team of engineers and technicians?

Ans: As a Chief Engineer, I’ve led a team of 10 engineers and techs. I like to create a positive and teamwork-focused space where everyone is motivated. We celebrate both the team’s wins and each person’s work. We meet often to talk about our goals and who’s doing what. If any problems come up, I’m good at finding solutions. With me in charge, we’ve finished many projects on time and within the budget.

Q8-Handling Unexpected Breakdowns at Sea: What’s Your Approach?

Ans: When something breaks on the ship, I quickly figure out what’s wrong and why. I look at the ship and check the engine logs for clues. Then, I decide what needs fixing first and tell the crew the plan. I’ve gotten good at fixing things fast on the sea, even when it’s stressful. I know how to make the right choices to keep everyone safe and the ship running smoothly.

Q9-Can you discuss your experience in formulating preventative maintenance strategies for marine vessels?

Ans: As Chief Marine Engineer, I’ve made many plans to stop problems before they start on different ships. I worked with teams to make careful lists of things to regularly check and fix. I also talked to suppliers to get the parts we need. I think planning ahead helps ships work better and avoids sudden big repairs. I’m excited to use this knowledge at your organization.

Q10-Keeping Up with Marine Engineering: How Do You Stay Updated?

Ans: I always make sure to keep learning about new things in marine engineering. I read newsletters, and magazines, and join webinars to stay updated. I also go to conferences and workshops when they’re useful. I even get special training and certificates. Everything I learn enhances how I perform my duties and makes things run more smoothly.

Q11-Can you share your method for guaranteeing equipment calibration and functionality?

Ans: In my role as Marine Chief Engineer, I employ a proactive strategy to guarantee that all vessel equipment is calibrated and functions as required. Regular inspections of all systems and components are part of my routine, in addition to checking for compliance with safety standards. With my extensive knowledge of the latest technologies and equipment, coupled with my comprehensive certifications in marine engineering, I’ve consistently maintained optimal efficiency of all systems during my eight-year tenure in this role.

Q12-Could you recount an experience where you managed a significant repair task at sea and how you tackled it?

Ans: There was an instance when I had to spearhead a significant repair project during a sea voyage. The ship experienced a propulsion system failure. I promptly gathered my team of engineers to evaluate the issue and brainstorm a remedy. Upon diagnosing the problem and outlining the required repairs, I assigned tasks to my team members to ensure swift and efficient completion. Owing to our concerted efforts, we were able to restore the vessel’s functionality promptly, averting any extended downtime.

Q13-Could you share any experience you have in overseeing dry dockings or major refurbishments?

Ans: My career has given me ample opportunities to supervise dry dockings and significant refurbishments. My supervision has spanned various vessel sizes, from compact recreational boats to vast cargo carriers. Prioritizing safety in these projects is a given for me, and I always implement necessary measures to ensure the protection of all personnel. My track record reflects the successful completion of such projects within stipulated timelines and budgets, and I am confident I can replicate this success in your organization.

Q14-What is your course of action if you encounter inconsistent readings from two distinct equipment pieces?

Ans: In case of inconsistent readings between two separate equipment pieces, my initial step would involve thoroughly comparing the readings to pinpoint any inconsistencies. Next, I’d trace the root cause of the inconsistency and devise a solution to rectify it. Documentation is key in this process, as it allows us to keep track of issues and prevent similar occurrences in the future. My extensive experience with diverse engine room challenges equips me to efficiently tackle any discrepancies that might surface.

Q15-Can you detail your experience in regulating and supervising emissions from a ship’s engines?

Ans: I have a lot of experience with different ship engines, like diesel and gas turbines. I got special training in controlling emissions and have a certificate for it. I work to make ship engines pollute less. I do things like using fuel better, changing parts when needed, and adding special converters. Also, I do things to stop problems before they happen so everything works the best it can. Because of these efforts, we’ve used 10% less fuel and made 20% fewer emissions.

Q16-Could you elaborate on your experience in instructing crew members about appropriate safety practices?

Ans: In my capacity as the Chief Engineer aboard the MV Sukanya, imparting safety guidelines to new crew members was part of my responsibilities. My training approach was practice-oriented, making certain each team member comprehended the correct usage of safety gear and the optimal responses to emergency circumstances. Additionally, I conducted routine safety drills to ensure our team was equipped to handle any prospective risks. Holding certifications in First Aid and Handling Hazardous Materials, I’m well-equipped to ensure everyone is adequately versed in crucial safety procedures.

Q17-How do you adapt to evolving rules and norms in the marine sector?

Ans: I know how important it is to keep learning in the marine industry. I have a way to keep learning all the time. I read special books and go to meetings to learn the newest rules. I talk to other chief engineers to learn from them too. I use a computer to keep track of changes and make sure I know the latest rules. This helps me stay organized and make sure the ships I take care of follow all the important rules.

Q18-How do you manage your workflow when multiple tasks require immediate attention?

Ans: When presented with numerous immediate tasks, I begin by evaluating each task’s urgency and significance. The potential fallout from leaving a task unattended aids in determining my task priority. Additionally, I employ techniques for managing multiple tasks and, if necessary, distributing tasks among my team members. My primary goal is to ensure all tasks are completed in a timely and competent manner, with any potential hazards being mitigated.

Q19-Can you describe your approach in managing emergencies like fires or water ingress in the engine room?

Ans: In case of emergencies like fires or water ingress in the engine room, my initial focus is to guarantee the safety of the crew. I would quickly evaluate the situation and prioritize the necessary actions to manage the emergency. It’s absolutely essential to maintain composure and make rational judgments amidst such high-pressure situations. Therefore, I’d consult with my team and superiors as necessary while adhering strictly to established emergency procedures. My past experiences in dealing with such emergencies have equipped me well, and I am confident in my ability to tackle similar situations effectively.

Q20-Can you elaborate on your experience managing budgets and controlling costs in the context of marine engineering initiatives?

Ans: I have a lot of experience in managing money for marine engineering projects. I use different ways to make sure projects don’t spend too much money. I plan carefully, watch how things are going, and check money regularly. I’m also good at guessing if we might spend too much by looking at how things are selling. I’ve done well with money for engineering projects before, and I’m sure I can help your team with this too.

“Essential Qualities Every Marine Engineer Should Possess

The most important qualities of a marine engineer are:

Math Skills: Being good at math helps with calculations and measurements needed for ship work.

Engineering Knowledge: Knowing how ships and machines work is crucial.

Technical Skills: Being able to use, fix, and take care of machines and tools is a must.

Physics Understanding: Knowing how things move and work in the water helps with ship operations.

Design Abilities: Being able to plan and create designs for ship parts is important.

Thinking and Reasoning: Having good thinking skills helps solve problems and make decisions.

Attention to Detail: Paying close attention to small things is important for safety and efficiency.

Problem-Solving: Being able to solve complex problems helps in tricky situations on the ship.

All these qualities together make marine engineers skilled and capable in their job.

Which marine course is best?

Among the top marine courses after finishing 12th grade, there are several good options to consider:

Diploma in Nautical Science: Learn about navigation and ship operations.

Diploma in Marine Engineering: Focus on ship machinery and systems.

BE Marine Engineering: Study more about ship engines and technology.

B.Tech in Marine Engineering: Dive deeper into marine technology and systems.

B.Sc Maritime Science: Explore a broader range of maritime subjects.

BBA in Shipping Management: Learn about managing shipping businesses.

B.Sc in Ship Building and Repair: Understand how ships are built and fixed.

B.Sc Nautical Science: Study navigation and ship operations in detail.

The best course for you depends on your interests and career goals in the maritime field.

Blog post Conclusion

Becoming a Marine Chief Engineer is an important and satisfying career choice, but it comes with lots of different things to do.. You have to make sure things are safe, use fuel well, lead a team, and handle problems. This needs a mix of knowing how things work, being a good leader, and staying calm when things are tough.

Knowing the newest stuff in ships and rules is really important, and so is being good with money. With these skills, a Marine Chief Engineer can do well even in tough situations on the sea.

This blog post talked about all these things so that people who want to be marine engineers or already can understand what it takes to do a great job in this important job on ships.