Table of Contents

Marine Fitter Job Description

The maritime world has many different activities and is quite big. At the heart of a ship’s functionality and performance lies the machinery, and ensuring its optimal operation is the role of the Marine Engine Fitter. These experts are crucial for keeping a ship’s machinery running smoothly and safely during trips. Here are the ten important things they do:

- Routine Maintenance: A Marine Engine Fitter regularly inspects and maintains engines and associated equipment, ensuring they function efficiently. This job includes putting oil on parts that move, swapping out filters, and inspecting seals for damage.

- Fault Diagnostics: When machinery malfunctions, the fitter’s expertise is crucial. They figure out problems, understand data, and find out why the engine is acting strange.

- Repairs and Overhauls: Beyond just diagnosing issues, a Marine Engine Fitter is proficient in repairing or overhauling machinery. This might include replacing worn-out parts, fixing leaks, or even conducting major overhauls for machinery reaching the end of its service life.

- Machinery Installations: New machinery or upgraded systems often require expert installation. The fitter ensures these systems are correctly integrated into the existing setup, tested, and run smoothly.

- Safety Checks: Safety is paramount on board. The Marine Engine Fitter regularly checks safety devices, pressure valves, and emergency systems, ensuring they’re in top condition and functioning correctly.

- Documentation: A ship operates on records. Every time they fix, repair, or put something new in, it’s really important to write down all the details. The fitter keeps records of everything they do, which helps in figuring out problems later and makes sure they follow the rules.

- Coordination with Manufacturers: For specialized equipment, coordination with manufacturers or suppliers might be necessary. The fitter plays a liaison role, ensuring the right parts are sourced and any warranties or guarantees are honored.

- Training Junior Crew: A Marine Engine Fitter often takes on a mentorship role, training junior crew members, imparting essential skills, and ensuring the next generation is equipped to manage the ship’s machinery.

- Ensuring Environmental Compliance: With increasing focus on environmental regulations, the fitter ensures the machinery operates within permissible emission levels, and waste is disposed of as per guidelines.

- Emergency Response: In cases of machinery breakdowns during voyages, the Marine Engine Fitter takes charge, employing their expertise to quickly address and rectify issues, ensuring minimal downtime and disruptions.

Marine Engine Operation: The Integral Role of the Marine Engine Fitter

Operating marine engines is a complicated job because they have to work in tough conditions. For the safety and efficiency of the ship, Maintenance plays an important role.

That’s where the Marine Engine Fitter comes in – they’re like the bridge between making the engine run and making sure it stays in good shape.

- Startup and Shutdown Procedures: Before an engine can be started, the Marine Engine Fitter checks various parameters such as oil levels, water coolant levels, and the condition of belts and pulleys. Post-operation, the fitter ensures the engine is shut down correctly, preserving its lifespan.

- Monitoring Operational Parameters: During the engine’s operation, various parameters like temperature, pressure, and RPMs need to be within specific limits. The fitter not only monitors these parameters but also understands the reasons for any discrepancies and can take immediate action if needed.

- Lubrication and Cooling Systems: Proper lubrication and cooling are paramount for an engine’s smooth operation. The Marine Engine Fitter makes sure these systems are working at their best, stopping them from getting too hot or worn out.

- Fuel System Management: From fuel injection systems to exhaust systems, the fitter ensures the engine receives the right amount of fuel, burns it efficiently, and any waste products are appropriately managed.

- Alignment and Balancing: A small misalignment or imbalance in the engine components can lead to significant issues. The Marine Engine Fitter ensures that all parts are aligned correctly and that the engine runs smoothly without excessive vibrations.

- Managing Auxiliary Systems: Marine engines come with various auxiliary systems like turbochargers, air compressors, and oil purifiers. The fitter ensures these systems work in tandem with the main engine, enhancing its performance.

- Emergency Protocols: In case of sudden malfunctions or emergencies, the Marine Engine Fitter is well-versed in emergency shutdown procedures, isolating the problem, and ensuring the safety of the vessel and crew.

- Tuning and Calibration: To keep the engine running at peak efficiency, periodic tuning and calibration are necessary. The fitter ensures that the engine’s settings are optimal for the operating conditions.

- Integration with Automation: Modern marine engines are integrated with automation systems that offer real-time monitoring and diagnostics. The Marine Engine Fitter is proficient in working with these systems, interpreting data, and taking corrective actions when necessary.

- Upgrades and Modifications: As engines age or as newer technologies emerge, there might be a need for upgrades or modifications. Without changing the engine’s original running conditions, Marine fitters make the changes as per the requirements.

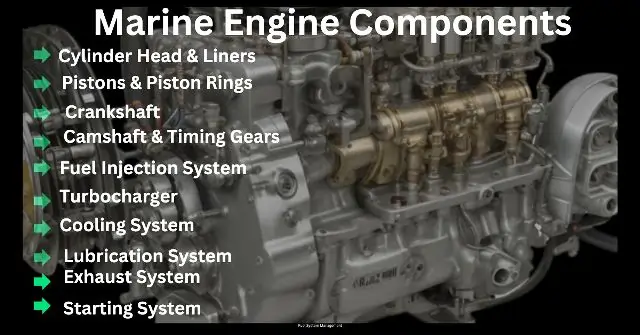

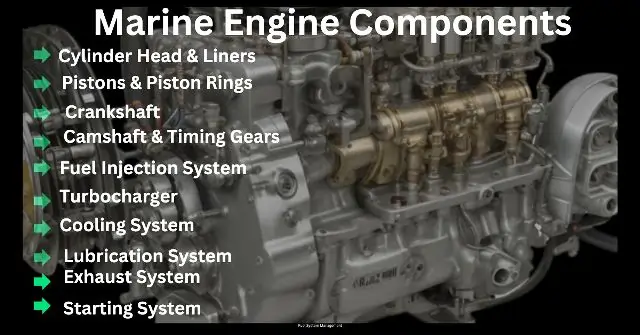

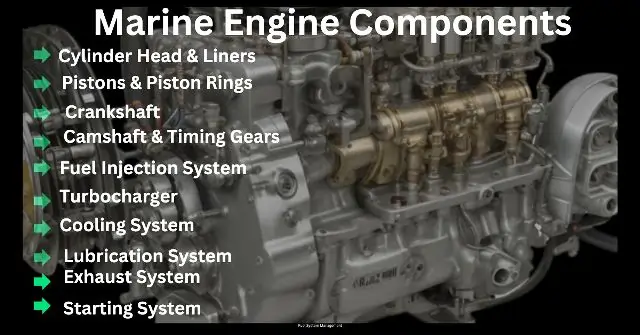

Marine Engine Components: The Marine Engine Fitter’s Domain

The engine of a ship is like its heart, made up of many parts that work together to move the vessel. Each of these components requires precise fitting, maintenance, and understanding – and that’s where the expertise of a Marine Engine Fitter comes into play. Let’s look at the important parts of a marine engine and see what the Marine Engine Fitter does with each of them.

- Cylinder Head & Liners: These are the chambers where fuel combustion takes place. The fitter ensures that the cylinder heads are securely bolted, the liners are free from scoring, and the sealing is effective in preventing any leakages.

- Pistons & Piston Rings: Pistons move up and down within the cylinder liners. The fitter ensures that pistons are free from cracks, the piston rings provide a good seal, and there’s adequate lubrication to minimize friction.

- Crankshaft: This transforms the linear motion of the pistons into rotational motion. A Marine Engine Fitter checks for any misalignments, wear, and tear, and ensures that the bearings are in good condition.

- Camshaft & Timing Gears: These control the opening and closing of the engine’s valves. The fitter ensures they’re synchronized correctly with the engine’s operation.

- Fuel Injection System: This system delivers fuel into the cylinders. The fitter’s role is to ensure injectors are clean, the fuel pumps operate efficiently, and the overall system maintains the right fuel pressure.

- Turbocharger: This boosts the engine’s efficiency by forcing more air into the combustion chambers. The fitter ensures that the turbocharger is free from deposits, its blades rotate freely, and there are no oil leakages.

- Cooling System: Comprising of pumps, coolers, and thermostats, this system keeps the engine at the optimal temperature. The Marine Engine Fitter ensures there’s no scaling in the coolers, the coolant circulates properly, and the system remains leak-free.

- Lubrication System: Ensuring smooth operation, this system reduces friction between moving parts. The fitter checks for the quality and level of oil, ensures oil pumps and purifiers work correctly, and replaces oil filters as necessary.

- Exhaust System: This system vents out the combustion gases. The fitter ensures there are no blockages and that exhaust gas boilers (if present) are functioning correctly.

- Starting System: Comprising of air compressors and starting valves, this system initiates the engine’s operation. The Marine Engine Fitter checks the compressors’ condition, ensures there’s adequate air pressure, and that starting valves are leak-free

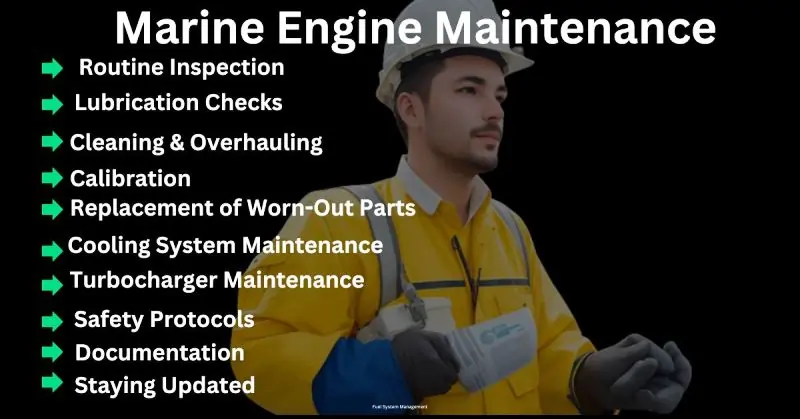

Marine Engine Maintenance: The Marine Engine Fitter’s Pivotal Role

Taking care of a ship’s engine is super important. We want it to work really well, stay safe, and last a long time. That’s where the Marine Engine Fitter comes in. They’re like the heroes who make sure the engine is in top shape. They use what they know about engines, their hands-on skills, and a forward-thinking attitude to make sure everything goes smoothly. Let’s see how the Marine Engine Fitter becomes the key player in taking care of ship engines.

- Routine Inspection: Marine Engine Fitters conduct periodic inspections of the engine components. This helps in the early detection of wear and tear, ensuring timely interventions before a minor issue escalates into a major problem.

- Lubrication Checks: A fitter ensures that all moving parts of the engine are adequately lubricated. They regularly monitor the lubrication system, change oils when necessary, and ensure that the oil purifiers and filters are in prime condition.

- Cleaning & Overhauling: Over time, engine components can accumulate dirt, sludge, or other contaminants. Marine Engine Fitters oversee the cleaning processes, and when necessary, dismantle parts for thorough overhauls.

- Calibration: To ensure the engine’s efficiency, certain components like fuel injectors and pumps need periodic calibration. A fitter performs the calibration with the help of special tools and instruments to ensure efficient combustion and engine performance to the optimum level.

- Replacement of Worn-Out Parts: Marine Engine Fitters are adept at recognizing parts that are beyond repair. They have the expertise to quickly replace such components, be it a piston ring, a valve, or a bearing, minimizing downtime.

- Cooling System Maintenance: Ensuring the engine doesn’t overheat is crucial. The fitter checks the freshwater and seawater cooling systems, ensuring pumps, coolers, and thermostats function effectively.

- Turbocharger Maintenance: A Marine Engine Fitter regularly checks the turbocharger for any deposits or obstructions. He also ensures the free movement of the blades to maintain the desired boost pressure.

- Safety Protocols: Maintenance isn’t just about fixing and cleaning; it’s also about ensuring safety. The fitter ensures that safety devices, such as relief valves, are operational and that the engine is compliant with all safety regulations.

- Documentation: Every maintenance activity, big or small, is documented. Marine Engine Fitters maintain logs that detail the work done, parts replaced, and any observations made during inspections.

- Staying Updated: The maritime industry is ever-evolving, with new technologies and maintenance methodologies emerging. A proficient Marine Engine Fitter stays updated with the latest trends, attending workshops and training sessions to ensure they employ the best maintenance practices on board.

Marine Engine Safety: The Marine Engine Fitter’s Vital Role

Safety in the maritime industry is paramount. In the complex ecosystem of a ship’s operations, the marine engine stands as the heart, and ensuring its safe functioning is a matter of both efficiency and human safety. Leading the way in this job is the Marine Engine Fitter. They’re like the guardians who use their skills to keep the crew, cargo, and ship safe. Let’s see why the Marine Engine Fitter is so important for making sure marine engines are safe.

- Routine Safety Checks: The Marine Engine Fitter carries out daily safety checks, examining alarms, shutdown systems, and safety valves to ensure they’re functional and ready to act in emergencies.

- Fire Prevention: The fitter regularly inspects fuel and oil pipelines for any leaks. They also make sure that the covering on hot parts is in good shape to stop any chance of fires starting.

- Fuel Handling: Proper handling and storage of fuels is crucial. The fitter makes sure that the machines that clean fuel, move it around, and store it are working safely, so there’s less chance of spills or leaks.

- Secure Fittings: Any loose fittings can pose a threat during operations, especially in rough seas. Marine Engine Fitters make sure that all components, from major parts to the smallest bolts, are securely fastened.

- Ventilation: Ensuring that engine rooms have adequate ventilation is critical to prevent the accumulation of harmful fumes. The fitter checks that the air systems are working really well, making sure the people near the engine room stay healthy.

- Emergency Protocols: In collaboration with other crew members, the Marine Engine Fitter plays a pivotal role in practicing and refining emergency protocols, be it for fire, engine failure, or other critical situations.

- Proper Tool Use and Maintenance: Tools that are damaged or misused can be dangerous. The fitter ensures that all tools are in good condition, stored safely, and used correctly to prevent accidents.

- Safety Gear Compliance: When people are working in the engine room, the fitter makes sure everyone has the right safety gear like helmets, gloves, goggles, ear protection, and other things to stay safe.

- Hazard Communication: The Marine Engine Fitter is trained to recognize potential hazards. They take the responsibility to communicate these risks to fellow crew members, ensuring everyone is aware and can take precautions.

- Continuous Learning: Maritime safety regulations and best practices are continually evolving. A dedicated Marine Engine Fitter keeps itself updated with the latest safety guidelines, ensuring compliance and implementing the most advanced safety measures onboard.

Marine Engine Fuel Systems: The Marine Engine Fitter’s Crucial Role

In the sea world, making sure the engine works really well and is safe is the most important thing. One of the most critical components in this equation is the marine engine’s fuel system. At the epicenter of its maintenance, troubleshooting, and optimal operation is the Marine Engine Fitter. Let’s see how the fitter does a really important job in taking care of the ship’s fuel systems.

- Fuel Quality Control: Marine Engine Fitters are responsible for ensuring the fuel’s quality, which includes checking for contaminants and water content. They verify the fuel quality by incorporating various techniques such as sedimentation tests.

- Fuel Transfer and Storage: Safely transferring fuel from storage tanks to day tanks without spillage or contamination is a vital task. The fitter ensures the fuel transfer pumps, pipelines, and valves are in optimal condition and function without leaks.

- Fuel Purification Systems: Marine engines often use fuel purifiers to remove impurities. The fitter looks after the purifiers that clean the fuel and makes sure they work well, so the engine gets clean fuel.

- Fuel injection system: Marine Fitter takes care of the fuel injection system, which makes the engine operation efficient with the best fuel economy. This system has things like injectors, fuel pumps, and timing devices. Marine Engine Fitters regularly inspect, clean, and calibrate these components to guarantee precise fuel delivery and combustion.

- Fuel System Troubleshooting: When issues arise, such as poor combustion or unburned fuel, the fitter uses their expertise to pinpoint problems within the fuel system. This could entail inspecting injectors, measuring fuel pressures, or assessing fuel quality.

- Emission Control: With stricter maritime regulations around emissions, the Marine Engine Fitter plays a part in ensuring the fuel system operates within these regulations. This includes monitoring emission levels and making necessary adjustments to the fuel system.

- Monitoring Fuel Consumption: An efficient fuel system leads to optimal fuel consumption. The fitter tracks fuel usage, identifying any discrepancies or inefficiencies that might indicate problems within the system.

- Fuel System Upgrades: As technologies advance and newer fuel types (like LNG or biofuels) become available, the Marine Engine Fitter is involved in upgrading or modifying the existing fuel systems to accommodate these changes.

- Safety Protocols: Given that fuel can be hazardous, the fitter ensures that all safety protocols related to fuel handling, storage, and combustion are strictly adhered to, minimizing risks of fire or explosions.

- Training & Knowledge Sharing: The Marine Engine Fitter often conducts or participates in training sessions, ensuring that all crew members are aware of the best practices when it comes to the fuel system’s operation and safety.

Marine Engine Lubrication Systems: The Integral Role of a Marine Engine Fitter

Lubrication is the lifeblood of any marine engine, ensuring smooth operation, reduced wear, and longevity. Given the engine’s size and complexity on ships, the lubrication system’s proper functioning is paramount. In this sphere, the Marine Engine Fitter stands as a guardian, ensuring the lubrication system works seamlessly. Here’s how the fitter is intricately linked to the marine engine’s lubrication systems.

- Understanding the Lubrication Needs: Marine Engine Fitters must be well-acquainted with different engine components’ lubrication requirements. This includes recognizing the specific lubricant type and the appropriate viscosity needed for each engine part.

- Lubricant Quality Check: Just like fuel, the quality of the lubricant is crucial. The fitter routinely checks for impurities, water contamination, or any degradation in the lubricating oil.

- System Maintenance: Marine Engine Fitters oversee the maintenance of the entire lubrication system. This includes cleaning and repairing oil pumps, and oil coolers, and ensuring the optimal functioning of oil filters.

- Monitoring Lubrication Levels: It’s crucial to maintain correct oil levels in various engine components. The fitter regularly checks and refills oil sumps, reservoirs, and other components, ensuring they never run dry.

- Lubricant Temperature and Pressure: Lubricating oil needs to operate within specific temperature and pressure parameters. The fitter ensures the correct operation of oil coolers and pressure pumps to maintain these parameters.

- Troubleshooting: When bearings overheat or when there’s excessive wear detected in engine components, the fitter troubleshoots to determine if the lubrication system is at fault. This might involve checking oil flow rates, oil quality, or system blockages.

- System Upgrades: As marine engines evolve, so do their lubrication needs. Marine Engine Fitters play a role in updating or modifying the existing lubrication system to suit newer engine models or updated specifications.

- Safety Protocols: Oil leaks or spills can lead to fire hazards. The fitter ensures all pipelines, joints, and reservoirs are leak-proof. They also ensure that safety protocols are in place in case of any lubricant spillage.

- Waste Management: Used lubricating oil needs to be disposed of or recycled responsibly. The Marine Engine Fitter ensures that waste oil is stored appropriately and helps coordinate its disposal or recycling in line with environmental regulations.

- Training & Continuous Learning: The marine industry’s dynamics require fitters to stay updated with the latest trends in lubricants and lubrication technologies. Marine Engine Fitters often engage in continuous learning and may also train junior staff about the best practices in lubrication system management.

Marine Engine Cooling Systems: The Marine Engine Fitter’s Expertise

In the vast expanse of the sea, a ship’s engine is constantly working, generating a significant amount of heat. The marine engine’s cooling system ensures that this heat is effectively dissipated, preventing engine parts from overheating and maintaining optimal operational temperatures. At the helm of ensuring the seamless function of this cooling system is the Marine Engine Fitter. Here’s a dive into their intricate relationship with marine engine cooling systems.

- Understanding the Basics: A Marine Engine Fitter must be intimately familiar with the workings of different cooling systems—whether they are direct sea-water cooling systems, indirect freshwater cooling systems, or a combination of both.

- Routine Inspections: The fitter regularly checks the cooling system components, such as water pumps, heat exchangers, and cooling towers, for any signs of wear or damage.

- Maintaining the Cooling Medium: Whether it’s seawater, freshwater, or a coolant, the fitter ensures the cooling medium’s quality is maintained, checking for impurities or contaminants that might hinder heat dissipation.

- Flow Rate Regulation: The fitter ensures that the water or coolant flows at the optimal rate, adjusting pumps or valves as necessary, to ensure effective cooling.

- Addressing Blockages: Cooling channels and heat exchangers can get blocked with impurities or marine growth. The Marine Engine Fitter is responsible for clearing these blockages to maintain efficient cooling.

- Temperature Monitoring: It’s crucial to ensure the engine operates within the designated temperature range. The fitter constantly monitors temperature gauges and makes necessary adjustments to maintain optimal temperatures.

- Pressure Checks: A drop in pressure might indicate a leak or blockage. The fitter routinely checks the cooling system’s pressure and troubleshoots any anomalies.

- Component Repairs and Replacement: From time to time, parts of the cooling system, such as pumps, gaskets, or seals, might need repair or replacement. The fitter’s role is to ensure these parts are promptly attended to.

- Safety Protocols: Given that the cooling system operates under pressure and involves water or coolants at high temperatures, there are potential hazards. The Marine Engine Fitter ensures that safety valves function correctly and that the crew is aware of safety protocols in case of any system malfunctions.

- Continuous Learning and System Upgrades: With advancements in marine engineering, newer and more efficient cooling systems are introduced. The Marine Engine Fitter stays updated with these changes and may play a role in retrofitting or upgrading older systems on board.

Marine Engine Electrical Systems: The Crucial Role of the Marine Engine Fitter

The marine engine is not just a mechanical powerhouse; it is intricately intertwined with sophisticated electrical systems that ensure its optimal functioning.

These electrical systems are really important because they help start the engine, keep an eye on it, control it, and make sure it’s safe. At the crossroads of this convergence of mechanical and electrical systems stands the Marine Engine Fitter, ensuring harmony and seamless operation. Let’s look at how they help with the electrical systems on marine engines, and why it’s important.

- Understanding Electrical Schematics: A Marine Engine Fitter must be adept at interpreting and understanding the electrical schematics associated with the marine engine. These drawings show how to connect electrical things, like wires, parts, and circuits.

- Routine System Checks: Regular inspection of starters, alternators, sensors, and control panels falls under the fitter’s responsibilities. They make sure all these parts work the way they should, and there are no strange problems with how they work.

- Wiring and Connection Maintenance: Wires, connectors, and terminals in marine engines are exposed to a corrosive environment. The fitter frequently checks these for signs of wear, corrosion, or damage and replaces or repairs them as necessary.

- Battery Management: Batteries are crucial for ignition and other auxiliary functions. The fitter ensures that they remain in top condition, checking their charge, and ensuring connections are clean and tight.

- Sensor Calibration: Various sensors monitor temperature, pressure, RPM, and more. The fitter checks that these sensors are set up right, so the numbers they show tell us exactly how the engine is doing.

- Safety Systems: Emergency shutdown systems, alarms, and other safety-related electrical components are regularly tested and maintained by the Marine Engine Fitter, ensuring they activate when needed.

- Troubleshooting and Diagnostics: When there’s an electrical fault, the fitter employs diagnostic tools and expertise to locate the issue, be it a faulty sensor, a malfunctioning control panel, or a short circuit.

- Integration with Control Systems: Modern ships come equipped with advanced control systems that centralize the monitoring and control of various functions, including the engine. The fitter ensures that the engine’s electrical components integrate seamlessly with these systems.

- Updates and Upgrades: With rapid technological advancements, marine engines are constantly evolving. The Marine Engine Fitter stays updated with new electrical components or systems, retrofitting older systems or installing new ones when necessary.

- Training and Skill Development: As electrical systems become more advanced, there’s a continuous learning curve. The fitter goes through training and learns new skills to make sure they can work with the latest electrical systems on ships.

Marine Engine Emissions Control: The Pivotal Role of the Marine Engine Fitter

In the past few years, people have become really worried about the environment and climate change. They’re paying a lot of attention to the stuff that comes out of ship engines because it can make the air dirty. There are strict rules now that say how much dirty stuff can come out of big ship engines.

Because these rules are getting tougher, the Marine Engine Fitter’s job is super important. They have to make sure the engine follows the rules and works well.

- Understanding Regulations: Different groups from around the world, like the International Maritime Organization (IMO), have made rules about how much pollution ships can make.. A Marine Engine Fitter must be well-versed with these regulations, ensuring that the engines they work on comply with the mandated limits for nitrogen oxides (NOx), sulfur oxides (SOx), and other pollutants.

- Emissions Monitoring: Modern marine engines are equipped with emission monitoring systems that continuously track the levels of pollutants. The fitter checks that these systems are working really well and keeping track of how much pollution the ship is making.

- Maintaining Exhaust Gas Cleaning Systems: Many ships use exhaust gas cleaning systems, or “scrubbers,” to reduce pollutants. Marine Engine Fitters are in charge of making sure these systems are fixed when they break and work really well all the time.

- Selective Catalytic Reduction (SCR): SCR systems are used to reduce NOx emissions by injecting a urea solution that reacts with NOx to form harmless nitrogen and water. The fitter ensures the correct functioning of SCR, from urea injection systems to catalysts.

- Ensuring Fuel Quality: With the recent regulations limiting sulfur content in marine fuels, it’s crucial to ensure that ships are using compliant fuel. The fitter plays a role in monitoring fuel quality, ensuring it meets regulatory standards.

- Optimizing Combustion: Efficient combustion can significantly reduce harmful emissions. Marine Engine Fitters regularly check and adjust engine parameters to ensure optimal combustion, minimizing the release of unburnt hydrocarbons and other pollutants.

- Retrofitting Older Engines: Many older engines aren’t compliant with current emissions standards. Fitters have an important job in upgrading these engines with new systems that control emissions, so they can follow the rules.

- Regular Training: Emissions control technology is rapidly evolving. Marine Engine Fitters must undergo regular training to stay updated on the latest advancements and best practices in emissions reduction.

- Collaboration with Environmental Officers: On many ships, especially larger vessels, there’s a designated environmental officer responsible for overall environmental compliance. The Marine Engine Fitter works closely with this officer, especially when it comes to engine emissions.

- Documentation & Reporting: Proper documentation of emissions, maintenance routines, and any corrective actions taken is essential for regulatory compliance. The fitter makes sure they keep really good records, which helps tell the authorities what’s going on.

Conclusion

Marine engine fitters are extremely important in the maritime industry today. Their job goes beyond basic maintenance due to ever-changing rules and new technology. They look after both the environment and how well engines work, ensuring that big ship engines are as eco-friendly as possible.

FAQ on ” Marine Engine Fitter”

Question: What does a Marine Engine Fitter do?

Answer: Inspects, diagnoses, repairs, installs, and maintains marine engines.

Question: What are the qualifications for a Marine Engine Fitter?

Answer: Strong understanding of marine engines, ability to use tools, and work safely in a marine environment.

Question: Where can I get training to be a Marine Engine Fitter?

Answer: Marine engineering school, apprenticeship program, or on-the-job training program.

Question: What is the job outlook for Marine Engine Fitters?

Answer: Good, as the demand for marine engines is expected to grow in the coming years.